Applications of cnc tube bender

With the development of the science and technology of tube bending machine, the types of cnc tube benders are increasingly diversified and the performance of cnc tube bender is also improved greatly. The development of the cnc tube bender software is particularly rapid. This allow the cnc tube bender for sale to become more powerful, more efficient, more labour-saving and more accurate in pipe bending and cnc tube benders can bend pipes in complicated shape. In the future, cnc tube and pipe bender will replace the traditional tube bender manual as main equipment for modern pipe bending.

CNC tube benders for sale can be widely used for all kind of production and manufacturing of modern enterprises.

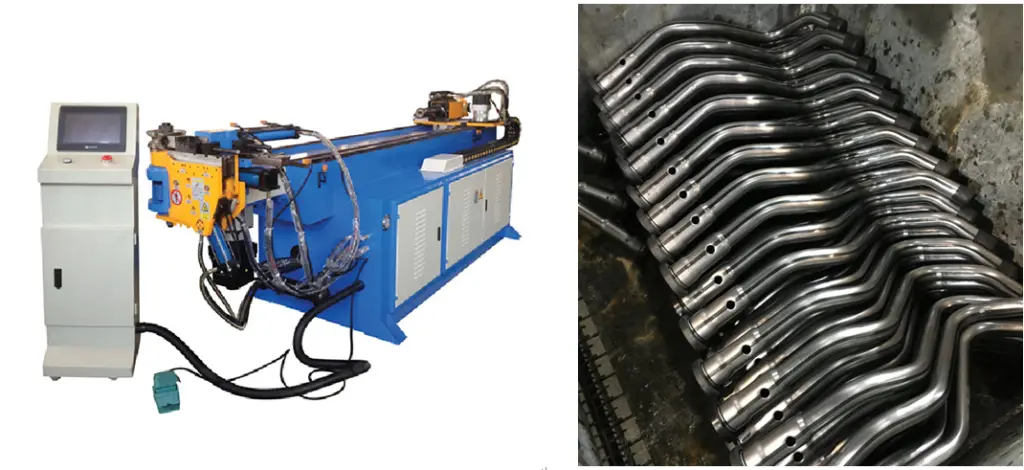

● 1. 3 axis cnc tube bender in production of auto-parts.

With the rapid development of the automobile industry, the demand for auto-parts increased rapidly, too, especially, the demand for pipe bending for exhaust pipe and radiator pipe. Exhaust pipe and radiator pipe produced by 3 axis cnc tube bender can not only fulfill the job with the engine bit only have beautiful shape. The application of cnc tube benders in automobile industry becomes more and more extensive and popular.

It’s necessary to create several bends on the same pipe and those bends may have different bending radius when produce exhaust pipes of automobile. It’s very complicated if produce this kind of exhaust pipes with a manual tube bender: one sets of manual tube bender dies only can create bend with same bending radius one time, so if we want to create bends with several bending radius we need to change manual tube bender dies. More important, the bending accuracy is not guaranteed when we use the manual tube bender to do this job. A multi-layer dies cnc mandrel tube bender for sale can do this job at one time and it has higher accuracy. And using the cnc tube bender machine to do the production is more labour-saving. The cnc tube bender machine is becoming more and more popular among the automobile exhaust manufacturers.

The cnc hydraulic tube bender is also used to produce roll bar for pick-up. Pipes used for roll bar can be carbon steel pipe and stainless steel pipe. Bending these pipes with cnc hydraulic tube bender can ensure the beautiful appearance of the pipes, which the manual tube bender can not make it.

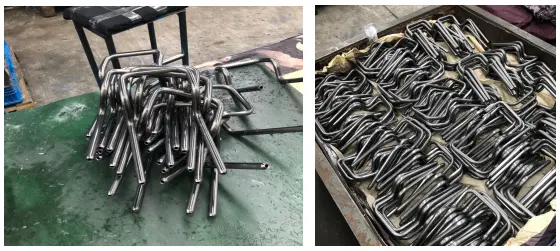

2. CNC tube and pipe bender in furniture industry

There are obvious difference between production of office chair with cnc square tube bender and with manual tube bender, especially when the chair is in complicated shape. It’s necessary to measure length between bends and feeding distance and to change bending angles in several directions. It’s very completed in bending procedure and more important, there will be a certain error in the bending angles, which will lead to asymmetry of the two sides of the chair or wrong size at both ends. This will cause a waste of pipes. On the contrary, producing chairs with the cnc square tube bending machine can do the bending and forming job once only and greatly reduces the complexity of the bending process. The cnc tube bender for sale can fulfil the bending job automatically after the cnc tube bender for sale operator inputs all bending data in the machine. This kind of bending method can ensure not only the bending accuracy but also the bending quality. At the present time, the cnc square tube bender is widely used in the furniture industry, it’s gradually replacing the manual tube bender which was commonly used before.

3. Small diameter cnc tube bender for refrigeration equipment.

Pipes for refrigeration equipment have small diameter and very complicates shapes, at the same time, these pipes require very high precision because they will be installed in other parts. YANSUMI MACHINERY produced small cnc tube bender according to these requirements. This small diameter cnc tube bender is equipped with 3 servo motors. The automatic feeding, automatic rotation of pipes and bending are under precise control of these servo motors. Complex bending work becomes very simple with this small diameter cnc tube bender for refrigeration, thus, the small cnc tube bender becomes very popular among the refrigeration equipment manufacturers.

4.CNC mandrel tube bender for bicycles and motorcycles.

CNC tube bender machine is used to produce bicycle rudder and motorcycle rudder. There are 3 or 4 bends on the same pipe and the cnc tube and pipe bender can do this work perfectly and in very short time.

The demand for motorcycle backrests is increasing recently, manufacturers of backrests are looking for improvement both in appearance of backrests and in production procedure. As cnc tube benders supplier of these factories, YANSUMI MACHINERY does production based on customer requirements. The cnc tube bender for sale of YANSUMI MACHINERY plays an important role in the production of motorcycle backrests. Backrests produced by this cnc tube bender machine do not need other procedure for shape forming. This can greatly shorten the production time and it’s very labour-saving.

5. Big diameter cnc tube benders for pipes in construction.

In road construction often needs to lay pipes for transporting natural gas and water. These bent pipes in large diameter can guarantee the integrity and are more resistant. Big diameter cnc mandrel tube bender of YANSUMI MACHINERY is very powerful and can bend pipes in big diameter.

In this article we talk about some applications of cnc tube benders of YANSUMI MACHINERY. And the powerful and multifunctional cnc tube benders can serve in more industries. You can read our blog for more information about the cnc tube benders.

+86 19112905173

+86 19112905173