wall formwork

● wall formwork define

Wall formwork is a temporary structure utilized in construction to support the pouring of concrete. It is typically employed for erecting vertical structures such as walls and columns, with its primary function being to ensure that the concrete maintains the desired shape and dimensions throughout the pouring and curing process. The construction of wall formwork is relatively straightforward, primarily used for the installation of formworks at shear wall locations. After the reinforcement of the wall, plumbing and electrical works are completed, and the necessary inspections are done, the assembly of shear wall formwork can commence. During the construction process, wall formwork is placed in its designated position, and concrete is poured into it. Once cured, the formwork can be dismantled, leaving behind a fully intact wall structure.

There are various types of wall formwork available, including metal formwork wall, plastic wall formwork, plywood wall formwork, timber wall formwork, and aluminium wall formwork, among others. The choice of wall formwork depends on several factors, including the required load-bearing capacity, construction duration, cost, and construction methodology.

Aluminium wall formwork systems, as an advanced construction formwork, hold a significant position in modern construction practices.

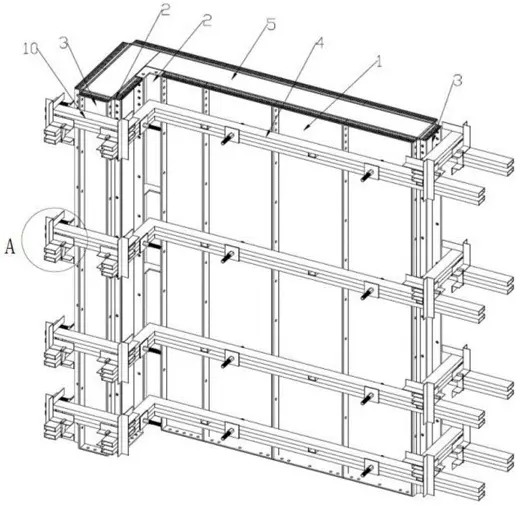

Aluminium wall formwork system consists of foundation wall formwork, formwork tie rods, and steel waler. These wall formwork components are interconnected using connectors and support rods to form a stable structure. The system is characterized by its lightweight, durability, and ease of installation and dismantling. It not only improves construction efficiency and quality but also reduces costs and saves resources.

● single sided wall formwork parameter

| single sided wall formwork parameter | ||||||

|---|---|---|---|---|---|---|

| Name | Size(L*W) | material | thickness | wall formwork weight | load | surface treatment |

| single sided wall formwork | 2600mm*400mm(customizable) | 6061-T6 | 4mm | 25kg/㎡ | 20kN/m² | Anodizing |

● Aluminium concrete wall formwork systems role

Aluminium concrete wall formwork systems are temporary structures utilized in construction, It mainly has the following functions

1. Formwork support: The wall formwork system provides support and shaping functions for the walls during the construction process. It allows the pouring of concrete inside the formwork, giving them specific shapes and dimensions.

2. Space partitioning: The wall formwork system can be utilized to partition different areas of space. It enables the division of the interior of a building into distinct rooms, zones, or functional spaces, meeting the requirements of the building's usage.

3. Lateral pressure resistance: The wall formwork system is capable of providing a certain level of lateral pressure resistance, ensuring that the walls are less prone to collapse during the construction process. This is particularly important for high-rise buildings or structures that need to withstand horizontal forces.

4. Surface smoothness: The surface of formwork wall systems is typically very smooth and even. After pouring the concrete, a smooth wall surface can be achieved, which is aesthetically pleasing and meets the design requirements.

5. Embedded piping: Formwork wall systems can be used for the embedding of pipes, such as electrical conduits and heating pipelines. By allowing space within the formwork, these fixtures can be conveniently installed and concealed.

It is important to note that concrete wall formwork systems are temporary in nature. Once the concrete has cured and achieved sufficient strength, the wall formwork is dismantled. Its purpose is to assist in the construction of the building, providing structural support and shaping, rather than becoming a permanent part of the structure.

● Aluminium formwork for concrete wall features

1. Improved construction efficiency: The assembly speed of aluminium formwork for concrete wall is fast, and the assembly and dismantling process is simple, which can significantly reduce construction time. Prefabricated holes and positioning features make installation more convenient, saving labor costs.

2. Lightweight and convenience: Aluminium wall formwork components are lighter compared to traditional wooden or steel formwork, weighing around 25kg per square meter. This makes them easy to carry and install. It also reduces structural loads and facilitates construction operations.

3. Adjustable height and reusability: The design of aluminium concrete wall formwork is scientific and adjustable, allowing it to adapt to the construction requirements of walls with different heights. The standard width is typically 400mm, but there are also supplementary wall formwork with widths of 350mm, 300mm, and 250mm. Additionally, it can be reused multiple times, reducing costs and minimizing waste.

4. Improved construction quality: Formwork for concrete wall exhibits high flatness and precision, ensuring the levelness and verticality of the walls. It also provides uniform pouring pressure, reducing the risk of concrete cracking and leakage.

5. No need for secondary plastering: By utilizing concrete formwork wall ties, the concrete surface achieves high flatness and smoothness, eliminating the need for secondary plastering. It can directly carry out the decoration on the wall surface.

6. Enhanced structural stability: Formwork for concrete wall enhances the lateral stability of structures such as beams and columns by providing additional stiffness and support. It reduces the deformation of the structure under lateral loads, thereby improving overall seismic performance.

7. Low wall formwork cost for aluminium: Despite the higher initial cost of aluminium formwork for concrete wall, the construction cost per usage gradually decreases due to its reusability. After exceeding 30 usages, the construction cost of aluminium wall formwork becomes significantly lower than timber wall formwork.

● Concrete wall formwork design

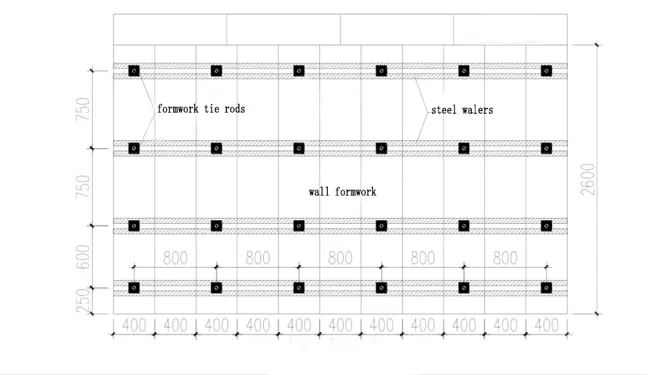

The wall formwork design adopts a formwork method with vertical 400*2600mm wall panels, with minor adjustments made in specific locations according to the actual conditions.

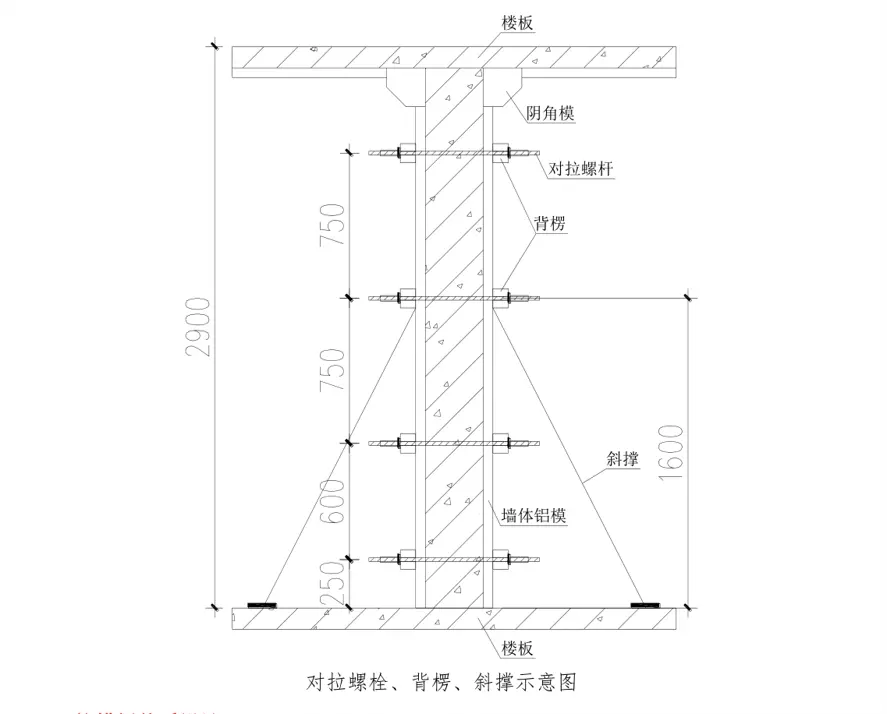

The formwork for wall incorporates M18 high-strength formwork tie rods. The horizontal spacing, from bottom to top, is set at 250mm, 600mm, 750mm, and 750mm. In the vertical direction, four rows of steel walers are installed with the ground serving as the reference level. The formwork for wall utilizes adjustable push pull props for lateral support. These braces are fixed to the ground using expansion bolts (or embedded rings), while the other end is bolted to the steel waler. They serve to enhance bending resistance and adjust verticality. The height of the diagonal brace is 1600mm, with a horizontal spacing of 2000mm. Please refer to the diagram below for illustration:

● Aluminium wall formwork procedure of construction

★ Installation of aluminium formwork for shear wall

The wall formwork procedure for aluminium is straightforward. After the completion of electrical and plumbing installation, the aluminium formwork for shear wall can be assembled. Initial reinforcement is done using dowel pins and wedges, followed by the installation of wall formwork ties. During this process, temporary support with push pull props should be employed to prevent potential tilting of the single-sided formwork. Finally, a detailed inspection of the wall reinforcement is conducted. If there are no major issues, the next step of the construction process can proceed.

When installing the formwork for the other side of the wall, it is important to assemble it according to the formwork code and the positions of the screw holes. During the assembly process, care should be taken to avoid damaging the embedded water and electricity pipeline in the wall. Prior to the installation of formwork for shear wall, a suitable amount of form release agent should be applied.

★ Reinforcement of shear wall formwork

At this point, the wall formwork ties are threaded through the holes in the aluminium shear wall formwork and secured with dowel pins and wedges. Once the dowel pins and wedges are in place, the diagonal brace rods can be gradually removed. During the assembly process, attention should be given to maintaining the verticality and smoothness of the aluminium shear wall formwork.

★ removel of aluminium shear wall formwork

The aluminium shear wall formwork can be removed after 12 hours when the concrete has achieved 50% of its strength. The removal process involves first dismantling the diagonal supports, followed by removing the wall ties for formwork, and finally removing the dowel pins connecting the formwork. A crowbar is then used to pry the formwork away from the wall, separating them. The disassembled formwork and accessories should be promptly cleaned and carefully stacked in the same location on the upper floor.

● Knowledge

What is the formwork for a wall consist of?

Wall formwork is a temporary structure used in construction to support the pouring of concrete. It consists of several components, including:

1. Foundation wall formwork: The foundation wall formwork is joined together by fittings to form a complete wall formwork system. Common materials for wall formwork materials include plywood, aluminium, steel, or plastic sheets, which are selected based on the load requirements and construction specifications.

2. Vertical supports: Vertical supports are used in wall formwork to provide stability and vertical alignment. These supports are typically made of wood, steel tubes, or metal columns.

3. Horizontal bracing: Horizontal bracing is employed to connect and reinforce the horizontal elements of the wall formwork. It can take the form of horizontal beams, struts, or rods, which help distribute the forces exerted by the concrete, ensuring the stability and durability of the formwork.

4. Fastening devices: Fastening devices are used to secure and support the wall formwork system. These devices typically include support rods, steel walers, or formwork flat ties that are used to connect, tighten, and adjust the position of the formwork to ensure it can withstand the required pressure during concrete pouring.

5. Wall formwork accessories: Wall formwork accessories encompass connectors, braces, adjustment devices, etc., which facilitate the assembly, adjustment, and dismantling of the formwork of wall. These accessories contribute to ensuring the accuracy, stability, and reliability of the formwork system.

By combining these components, wall formwork creates a temporary structure that provides support and shapes the concrete. It ensures that the concrete maintains the desired shape and dimensions during the pouring and curing process, thereby achieving accurate construction of the wall structure.

What Is Wall Formwork?

Wall formwork, also known as concrete retaining wall formwork, is a temporary structure used in construction to support and shape the concrete wall. The primary purpose of concrete retaining wall formwork is to ensure that the concrete maintains the desired shape and dimensions during the pouring and curing process. It provides necessary support and stability to ensure the quality and accuracy of wall construction.

There are various types of wall formwork, such as plywood, steel plates, or plastic sheets. Retaining wall formwork is composed of a series of components, including wall panels, vertical supports, fastening devices, horizontal bracing, and other accessories. Vertical supports are used to support and position the wall panels, while horizontal bracing reinforces the formwork structure and distributes the forces exerted by the concrete. Fastening devices are used to secure the formwork, ensuring its stability and load-bearing capacity. Other accessories such as connectors and push pull props can provide additional support to the formwork of retaining wall.

Formwork for retaining wall plays a crucial role in the construction process as it ensures not only the accuracy and quality of wall construction but also enhances work efficiency and safety. Once the concrete has fully cured, formwork for retaining wall can be dismantled and reused for other construction tasks.

● Recommended

+86 19112905173

+86 19112905173