Comparison of Different formwork for concrete

● what is formwork for concrete

Formwork for concrete refers to the template material used for pouring concrete, which serves the purpose of supporting the concrete and maintaining its shape.The common formwork for concrete includes timber formwork for concrete, steel formwork for concrete, and aluminium formwork for concrete, each possessing distinctive features. Depending on specific construction requirements and utilization, various materials of formwork for concrete can be selected. This article aims to compare these materials in terms of concrete formwork material, construction efficiency, construction quality, and sustainability. Additionally, it will emphasize the advantages of aluminium formwork.

● concrete formwork material comparison

★timber formwork for concrete

Advantage:

1.Low cost: Timber formwork for concrete is a traditional formwork for concrete that has a large supply in the market and relatively low production technology, resulting in intense competition and lower prices.

2.Easy to process: Timber formwork for concrete is relatively easy to process, allowing on-site customization to meet complex and specific shape requirements during construction.

3.Lightweight: Timber formwork for concrete primarily utilizes panels made from softwood or hardwood, resulting in a lightweight material weighing approximately 12kg/m². This characteristic enables easy handling and installation.

4.Good thermal insulation: Wood is a favorable thermal insulating material, which helps reduce temperature loss during the concrete pouring process.

Disadvantages:

1. Vulnerable to moisture and deformation: timber formwork for concrete is easily affected by environmental humidity and temperature, and is prone to deformation and cracking. It is necessary to pay attention to the storage and use environment.

2.Relatively short lifespan: Timber formwork for concrete has a limited service life and needs to be frequently replaced, resulting in increased costs and labor requirements.

3.Non-reusability: Timber formwork for concrete has a limited number of uses, typically around 3-5 times, as excessive reuse can lead to warping at the edges.

★ steel formwork for concrete

Advantage:

1.High strength: Steel formwork for concrete is made of high-strength steel, providing excellent resistance to bending and load-bearing capacity. It can withstand significant loads and pressures, offering stable support structures for large, complex, or high-rise construction projects.

2.Excellent durability: Steel formwork for concrete exhibits strong resistance to corrosion and oxidation, resulting in a longer lifespan.

3.Strong deformation resistance: Steel possesses high rigidity, making it less prone to deformation.

4.Reusability: Steel formwork for concrete can be reused multiple times, typically up to 50 cycles, reducing material consumption and waste.

Disadvantages:

1.High cost: Compared to some low-cost formwork for concrete, the manufacturing and purchasing costs of steel formwork for concrete are relatively high. Additionally, maintaining and servicing steel formwork for concrete also involves additional costs.

2.Heavy weight: Steel formwork for concrete is comparatively heavy, weighing around 35-50kg per square meter. It requires additional equipment and labor for handling and installation.

3.Poor heat conduction: Steel has low heat conduction properties, which may result in uneven temperature distribution during the concrete pouring process.

4.High noise during construction: Steel formwork for concrete generates significant noise during the installation and dismantling process, which can have an impact on the construction environment

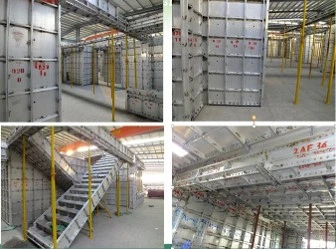

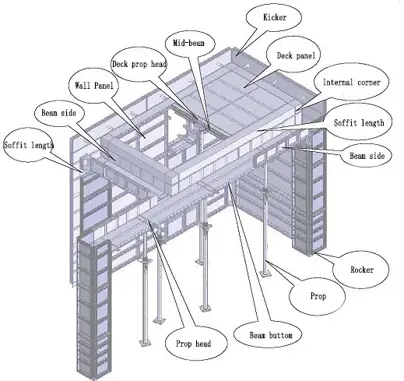

★ aluminium formwork

Advantage:

1.Lightweight: aluminium formwork is lighter than steel formwork for concrete slab, aluminium formwork weight is 21KG/㎡, which is easy to carry and install.

2.High strength: Aluminium alloy materials have high strength and rigidity, with a load-bearing capacity of up to 60KN per square meter, which can meet the requirements of most construction projects.

3.Strong durability: aluminium is resistant to corrosion and oxidation, and its surface is treated with anodization, giving it a longer lifespan.

4.Reusable: Aluminium formwork can be used repeatedly, often up to around 300 times, which helps reduce the consumption of resources and costs.

5.Good heat conduction: aluminium has excellent heat conduction properties, which helps facilitate uniform solidification of the concrete.

6.High construction efficiency: Aluminium formwork is easy to assemble and has a fast installation speed, resulting in improved construction efficiency.

Disadvantages:

1.Higher cost: Due to the complex aluminium formwork manufacturing process, the aluminium formwork profile is more expensive, resulting in a higher price of aluminium formwork compared to timber formwork for concrete slab.

● Comparison of construction efficiency for formwork for concrete

★ Timber formwork for concrete slab: Since timber formwork for concrete slab needs to be shaped and processed by skilled carpenters, the processing time is relatively slow.The concrete slab formwork removal time usually occurs after a period of 3 days, and both the installation and dismantling processes require a significant amount of time and labor. In comparison to steel formwork for concrete slab and aluminium formwork, timber formwork for concrete slab generally exhibits lower construction efficiency.

★ Steel formwork for concrete slab: Due to the heavy weight of steel formwork for concrete slab, installation and dismantling typically require mechanical assistance. This can potentially increase the time and labor cost during construction, thereby reducing construction efficiency.

★ Aluminium formwork: The lightweight and easy-to-use features of aluminium formwork make it highly efficient in construction. The aluminium formwork system can be easily removed, resulting in a construction period as short as one floor every four days, saving management costs for the construction company. The installation of aluminium formwork is simple and convenient, with a weight of 21KG/㎡, enabling it to be assembled entirely by manual labor without the need for any mechanical equipment. Each installer can install up to 30 square meters per day.

● Quality control comparison of formwork for concrete

★ Concrete formwork timber bunnings: The quality of concrete formwork timber bunnings is greatly influenced by humidity and processing accuracy. As wood is prone to moisture absorption and deformation, special attention needs to be paid to humidity control and processing accuracy when using concrete formwork timber bunnings, ensuring the surface smoothness of concrete formwork timber bunnings.

★ Steel formwork for concrete for sale: Due to its high strength and excellent rigidity, steel formwork for concrete for sale is resistant to deformation and provides stable template support, ensuring quality throughout the construction process.

★ Aluminium formwork: Aluminium formwork is known for its structural stability and precise dimensions, ensuring control over construction quality. The use of aluminium formwork in construction results in a smooth and even concrete surface with a flatness tolerance of 0-4mm and verticality tolerance of 0-4mm. This meets the requirements for fair-faced concrete, eliminating the need for plastering and saving costs and time associated with materials and labor.

● Comparison of sustainability in formwork for concrete

★ Concrete slab formwork timber: There are certain challenges when it comes to the sustainability of concrete slab formwork timber. Its relatively short lifespan requires frequent replacement, resulting in a higher demand for wood.

★ Steel formwork for concrete walls: Steel formwork for concrete walls can be reused multiple times, reducing material waste. However, the production and processing of steel typically require significant energy consumption, which can have an impact on the environment. To enhance the sustainability of steel formwork for concrete walls, energy-saving and emission-reducing measures can be implemented.

★ Aluminium formwork system for sale: Aluminium formwork system for sale is known for its reusable nature, typically allowing for approximately 300 reuses. As the number of reuses increases, the construction costs gradually decrease. When the number of reuses exceeds 60, the overall aluminium formwork cost becomes lower than the construction cost of concrete slab formwork timber. Additionally, aluminium formwork system for sale employs recyclable materials, with a recycling price ranging from 20% to 25% of the purchase price.

After analyzing the characteristics of timber formwork for concrete, steel formwork for concrete, and aluminium formwork for concrete, aluminium formwork has become a widely chosen option in the construction industry. This is primarily due to its lightweight design, high strength, durability, and the ability to be reused.Although the relatively higher aluminium formwork price is a factor to consider, its high construction efficiency and advantages in quality control can help save time and costs. Additionally, aluminium formwork aligns with sustainable development requirements and has a minimal environmental impact.Therefore, opting for aluminium formwork in construction projects is a great choice.

Recommended

aluminium formwork components

aluminium formwork construction and other types of work

aluminium advantages

+86 19112905173

+86 19112905173