formwork for slab construction

Formwork for slab is used in construction to support the pouring of concrete and create the structure of the slab. It plays a crucial role in bearing and securing the concrete, directly influencing the stability and quality of the building. The construction of formwork for slab is a critical step in building projects, as proper installation ensures the stability and safety of the entire structure. This article will provide a comprehensive overview of the steps and key points involved in the construction of formwork for slab, aiming to help readers gain a thorough understanding of the process and achieve better results in practical implementation.

● types of slab formwork

According to different purposes:formwork for floor slab, formwork for roof slab, formwork for flat slab, formwork for shed slab, deck slab formwork, bridge deck slab formwork, and raft slab formwork.

According to different materials:slab timber formwork,metal slab formwork,suspended slab steel formwork, aluminium formwork for slab, plastic formwork for slab.

The mentioned types of slab formwork are commonly used in construction. By selecting the appropriate formwork for slab based on project requirements and structural characteristics, construction efficiency and quality can be improved.

● slab formwork procedure of construction

The construction process of slab formwork procedure consists of preparation, installation of formwork for slab, inspection of formwork for slab, removal of slab formwork, and concrete curing.

1. During the preparation phase, it is necessary to clean up the construction site, ensuring it is level and free from debris. At the same time, the formwork for slab should be inspected to ensure its quality and reliability.

2. Next is the installation phase of the formwork for slab. Following the slab formwork diagram and specifications, a sturdy slab formwork system is set up to ensure it can withstand the weight of the concrete and the loads during the construction process.

3. During the inspection phase of the formwork for slab, it is necessary to refer to the slab formwork checklist to check for any issues such as loosening or deformation. Additionally, slab formwork leveling should be conducted to ensure an even surface for pouring the concrete.

4. After completing the concrete pouring process, it is necessary to proceed with the removal of slab formwork. Following the construction plan and procedure, the formwork for slab is gradually dismantled while taking care to avoid damaging the concrete structure. Once the removal is completed, the construction site is cleaned up, preparing it for subsequent processes.

5. Lastly, following the requirements for concrete curing, appropriate measures are taken to ensure the strength and durability of the concrete.

● formwork for slab preparation work

1. Before officially starting the installation of formwork for slab, the first step is to provide technical guidance and ensure that construction workers are familiar with the slab formwork method statement.

2. To ensure the quality of the formwork for slab installation, it is important to set up measurement control points at the construction site. This will make it easier to check.

3. According to the relevant requirements, an inspection is conducted on the formwork for slab and slab formwork parts. Any defective components must not be used in the construction project.

4. Before installing the formwork for slab, it is necessary to apply a release agent to prevent the concrete from sticking to the formwork. In the case of using beams and slab formwork support pillars in soil, it is necessary to level the ground first and then compact it.

5. During the installation of formwork for slab, it is essential to have a flat and solid bottom surface that meets the required standards. To ensure the stability of the formwork for slab, it is necessary to incorporate embedded support anchorages based on the specific conditions of the project.

● formwork of slab installation

★formwork of slab installation technology

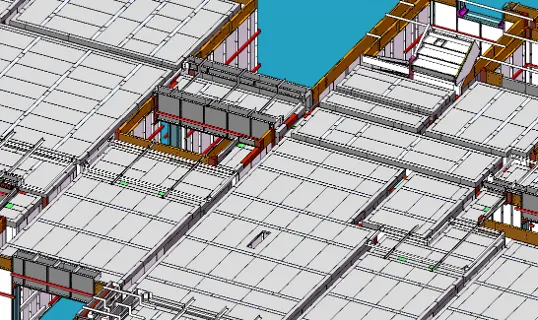

1. slab formwork system consists of Beam, slab formwork support, scaffolding for slab formwork, formwork of slab

2. The formwork of slab is connected and secured using pins and wedges, while the soffit formwork to slab is also connected and secured using pins and wedges.

3. Pins and wedges installation principles: For the soffit formwork, pins and wedges should be placed at both ends, and the distance between the pins and wedges in the middle should not exceed 300mm.

4. the formwork of slab and beam is joined together using pins and wedges. The formwork of slab is connected to the wall formwork using the soffit formwork.

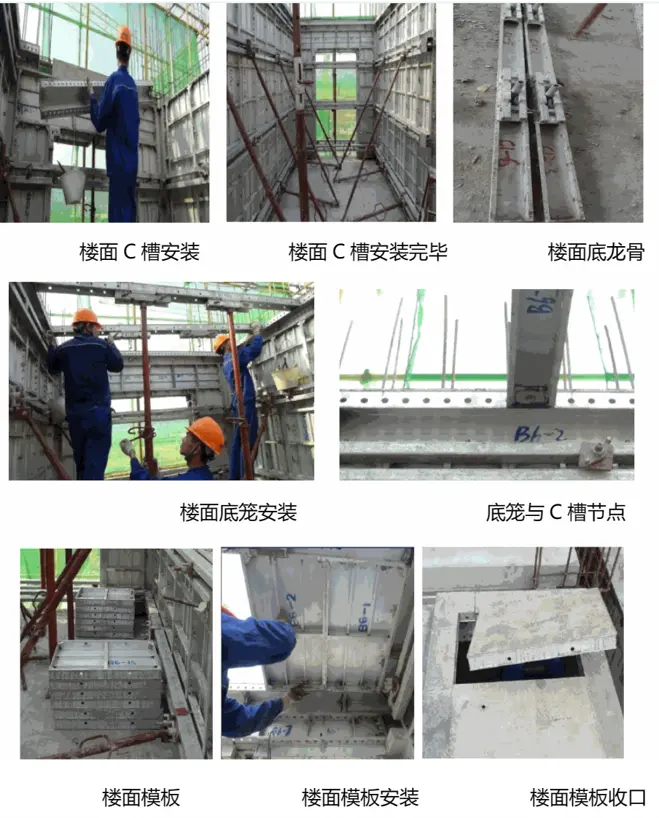

★ formwork of slab installation

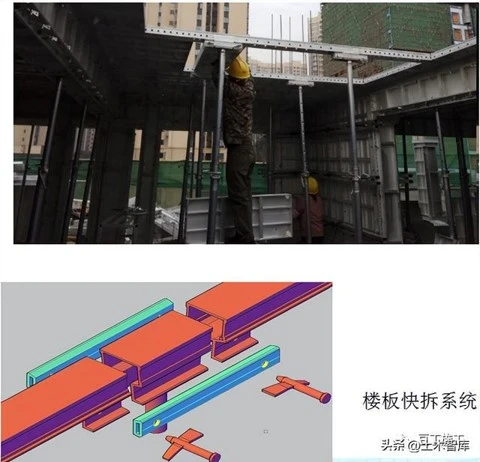

1.After installing soffit formwork at the top of the wall, the floor joists should be installed, and then the formwork of slab should be installed sequentially following the numbered drawing, until all parts are completely assembled. The slab formwork support should be vertical with no looseness.

2. After finishing the formwork of slab, it is necessary to adjust the slab formwork support to the appropriate position, ensuring that the surface of the board is level.

3.The arrangement and spacing of slab formwork support and steel walers should be determined based on the weight of the concrete and the magnitude of the construction load. Generally, the spacing between the slab formwork support is between 800 to 1200mm

★ Installation Notes for formwork of slab

1.Before installing the formwork of slab, it is necessary to inspect the spacing between the keel, with a requirement that the measurement deviation should be no greater than 3mm. If the deviation exceeds this limit, an adjustment to the keels will be necessary.

2. formwork of slab sequence: soffit formwork → formwork of slab keel assembly → fixed formwork of slab。

3. During the assembly process of formwork of slab, it is necessary to check if the positions of the reserved openings (including alignment holes, material transfer openings, and pre-embedded openings for water and electricity) are correct.

4. When installing the keel, it is essential to ensure that the support positions align with the design, and the supports should be erected simultaneously with the keel.

5.After the installation of formwork of slab, it is necessary to add push-pull props according to the push-pull prop placement diagram.

● slab formwork checklist

1. During the installation process of elevated slab formwork, it is important to pay attention to controlling the elevation and horizontal level.

2. The vertical deviation of slab formwork support should not exceed 50mm.

3. The variation in horizontal level for elevated slab formwork should be kept within a maximum of 5mm.

4. After the assembly and reinforcement adjustment of elevated slab formwork, a comprehensive inspection is required. The inspection includes checking the section dimensions, spacing and depth of the boards, diagonals of the boards, elevation, joint width, and variation in joint height.

5. Once the inspection is passed, the next step is to proceed with the reinforcement binding and subsequent work.

● ground slab formwork removal

1. The removal of ground slab formwork should be determined based on the specific conditions on-site, but typically it can be done after a period of 24 hours. It is advisable to begin by removing the pins and wedges before dismantling the ground slab formwork.

2.To ensure safety, it is essential to construct a work platform before commencing any construction work. During the removal of ground slab formwork, at least two individuals should collaborate together, using a mold puller to separate the peri slab formwork.

3.The ground slab formwork comes into prolonged contact with concrete, so it requires appropriate cleaning and oiling before pouring to facilitate easy removal. Once removed, the ground slab formwork should be cleaned immediately.

4.The removal of ground slab formwork must be carried out during daylight hours and should be done in sections. It is strictly prohibited to throw any components or objects from a height while dismantling, and proper cleanup should be conducted at the end of the work.

5.During thunderstorms, rain, snow, or when the wind speed reaches five or above, the removal of ground slab formwork must not be carried out.。

● concrete curing

1. After the completion of slab formwork for concrete, it is necessary to carry out curing. The temperature at the construction site should be controlled within the range of 5-35°C to avoid extreme weather conditions. In hot weather, it is important to extend the curing time and strengthen the curing measures. In cold weather, insulation measures should be taken to prevent the concrete from freezing.

2. During the curing period of slab formwork for concrete, it is important to avoid strong winds as they can cause premature drying of the concrete surface, compromising the effectiveness of curing. In the presence of strong winds, measures such as providing shade and protection should be taken to keep the concrete surface moist.

3. During the curing period of slab formwork for concrete, it is advisable to minimize exposure to direct sunlight. This is because sunlight can cause rapid drying of the concrete surface, affecting the effectiveness of curing. In hot weather with intense sunlight, shade measures should be taken to keep the concrete surface moist.

● Recommended

+86 19112905173

+86 19112905173