slab formwork

● what is slab formwork

Slab formwork is a critical component in the formwork system, widely used for constructing concrete floors. It forms a sturdy working platform by connecting and securing with other formwork components, providing support for concrete pouring and the entire construction process. Slab formwork materials come in a variety of options, including timber, steel, and Aluminium alloy, each with different advantages and applicable ranges.

Among various materials, aluminium slab formwork stands out for its excellent stability and is widely adopted in modern construction projects. aluminium slab formwork is a reusable formwork system that can be used repeatedly in multiple construction cycles, optimizing construction efficiency and reducing costs.

● Aluminium slab formwork system design

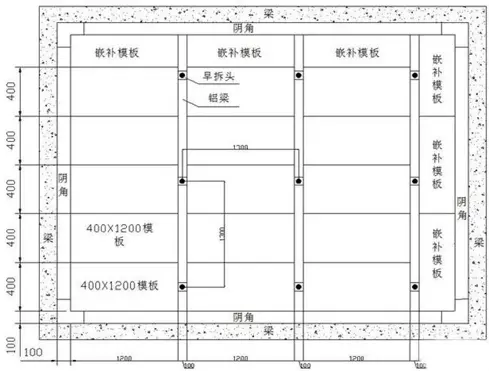

The standard size of aluminium slab formwork is 400x1200mm, with adjustments made to accommodate the actual structural dimensions in certain areas. The slab formwork thickness is 4mm, and a 100mm wide beam is provided on the floor, with a bottom support upright spacing of 1300mm x 1300mm. The basic distribution of slab formwork is shown in the diagram below:

● Aluminium slab formwork system structure and materials

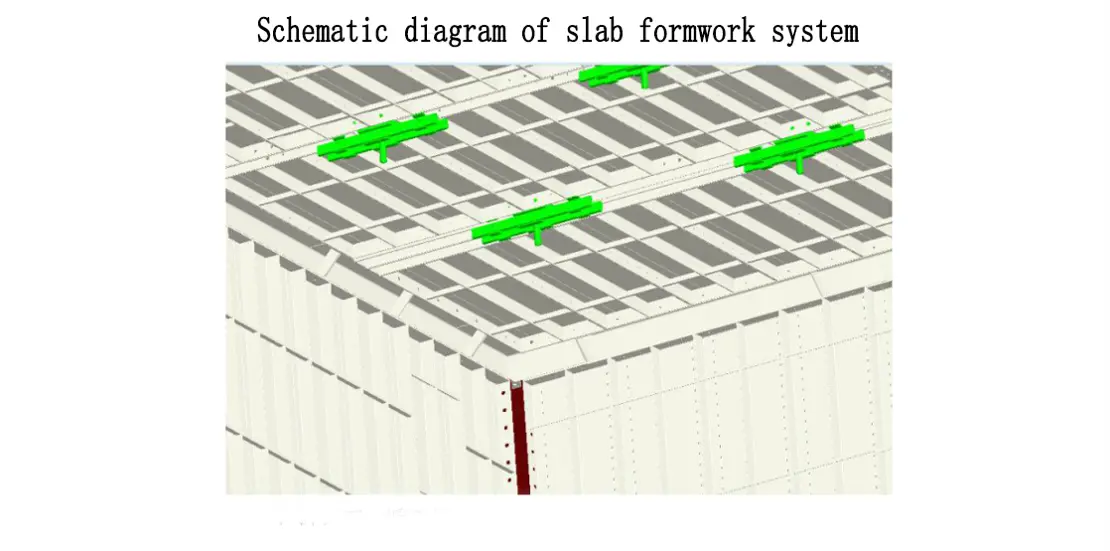

★ Structure of the aluminium slab formwork system

The aluminium slab formwork system is made of lightweight aluminium alloy material, featuring a design that is structurally simple and easy to assemble. The slab formwork structure consists of slab formwork, beams, support systems, and connectors. Slab formwork is typically made of flat and high-strength aluminium alloy sheets, while beams are used to reinforce and support the panels. Connectors are used to join the slab formwork and beams, ensuring the stability and load-carrying capacity of the entire formwork structure.

★ Materials of slab formwork components

The slab formwork components are made of high-strength aluminium alloy material, characterized by excellent weather resistance, corrosion resistance, and compressive performance. This material can withstand the loads during construction and maintain a long service life. Additionally, the lightweight nature of aluminium alloy makes aluminium slab formwork easier to transport and install compared to traditional wooden slab formwork. To enhance the corrosion resistance and surface hardness of aluminium slab formwork, it is commonly subjected to anodized treatment, which forms a layer of aluminium oxide film on the surface, protecting the aluminium material from environmental erosion. These surface treatments and corrosion protection measures can prolong its service life and maintain its excellent performance.

● Characteristics of aluminium Formwork for Slab

1. Load-bearing capacity: aluminium formwork for slab can bear significant loads, including the weight of concrete as well as the working loads of construction personnel and equipment. Its high-strength aluminium alloy material and structural design ensure excellent load-bearing capacity and stability.

2. Flatness: aluminium formwork for slab has a high surface flatness, ensuring the required flatness and levelness of the floor slabs, resulting in a more robust and stable building structure.

3. Construction efficiency: The design of aluminium slab formwork allows for rapid assembly and disassembly. Compared to traditional wooden formwork, it is simple and quick to assemble, eliminating the need for support structures and tedious finishing work. This significantly improves construction efficiency.

4. Quality Control: aluminium concrete slab formwork systems improve the quality of concrete pouring, ensuring a smooth and stable surface for floor slabs while reducing the risks of concrete cracking and deformation.

5. Safety: aluminium formwork for slab demonstrates excellent safety performance, providing a secure and reliable working platform for construction workers. Its stable structural design and dependable connection methods reduce the risks of workers slipping and falling.

6. Reusability: aluminium formwork for slab has a long lifespan and can be reused in multiple construction projects. Compared to traditional wooden formwork, it is more durable and less prone to damage, effectively saving material resources and labor costs.

Therefore, aluminium formwork for slab plays a significant role in improving construction efficiency, ensuring quality control, and providing safety in the field of building construction. Its widespread application has become an important technology in modern construction industry.

● Slab formwork procedure

★ slab formwork steps of Installation:

(1) Sequence of slab formwork system installation: Floor soffit → Installation of beams → Installation of formwork of slab panels.

(2) Start by installing the floor soffit, connected to wall formwork using pins.

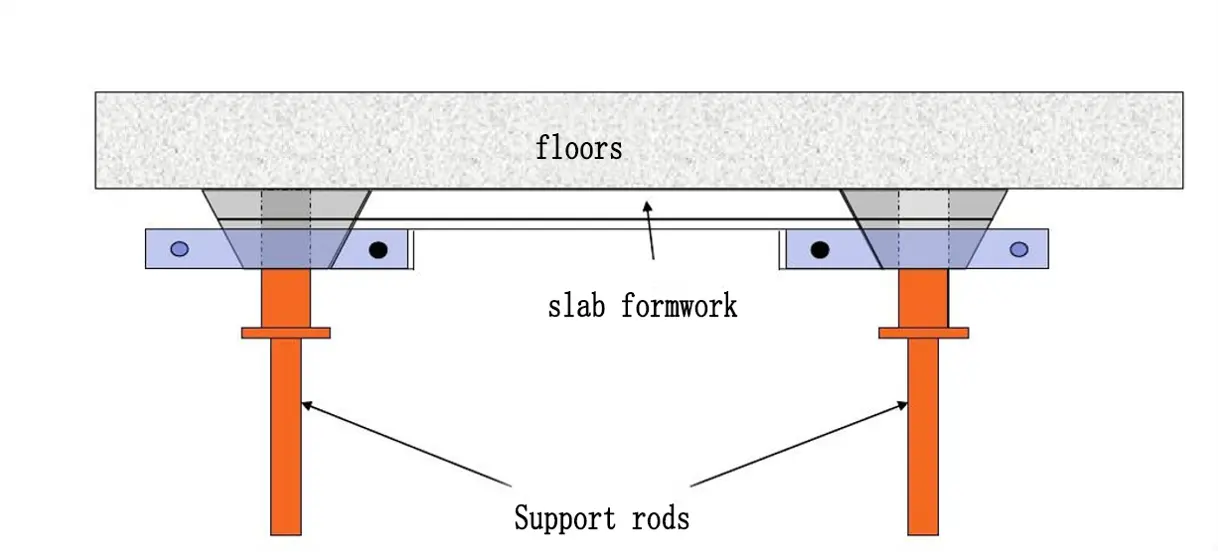

(3) Following the slab formwork drawing, two people should install the floor beams. Each beam's top must be secured with a support rod head(early dismantling head), and the formwork of slab panels should be placed parallel and installed one by one.

(4) Once all slab formwork is installed, Connect the support rod to the support head. The 400-type formworks should have at least 10 pins connecting them on all four sides.

★ Preliminary Reinforcement of formwork of slab

When assembling formwork of slab up to the support head, it is necessary to promptly reinforce and support it using prop rods. After the assembly of panel formworks is completed, the numbers of slab formwork support must not be less than 50% of the original support.

★ Overall Reinforcement of formwork of slab

Firstly, each lower part of the prop head should be equipped with a supporting vertical rod, and all of them should be tightened. Secondly, between formwork of slab should be done using nails and reinforcing plates, and the nails and reinforcing plates should be fully hammered in. Lastly, the wall formwork needs to be properly set up with diagonal braces and securely fastened. At this point, the slab formwork system is fully reinforced.

★ Slab formwork removal time

The slab formwork removal time is usually after 24 hours, but the actual timing may vary depending on the construction environment and local regulations. When removing top slab formwork, it is recommended to start from the positions of beams and panel support rods. Remove the pins securing the beams and panel support rods, as well as the connecting components. Next, remove the nails connecting the adjacent beams and panels before proceeding with the removal of the top slab formwork, Use a pry bar to detach the formwork and the concrete. Once removed, clean the formwork and slab formwork parts promptly and transport them to the same location on the upper floor for proper stacking.

Note: Ensure that the support rods remain intact and do not loosen during the removal process. Generally, the slab formwork support can be removed after 21 days.

★ Cleaning:

1. Start by removing debris and residues layer by layer from the house slab formwork.

2. Disassemble the connecting components one by one and separate the house slab formwork from the beams.

3. Clean the aluminium house slab formwork using water, cleaning agents, etc., ensuring that the surface of the formwork is clean and free from contamination.

During the dismantling and cleaning process, it is important to prioritize safety to avoid any harm to personnel or damage to materials. Additionally, proper disposal of waste and cleaning agents should be carried out in accordance with relevant regulations and requirements to protect the environment and maintain cleanliness at the construction site.

Note: The translation above is as per your request, but please note that the specific terminologies used in the construction industry may vary across regions and countries. It is important to adapt the translation to the local standards and practices.

● Competitive advantages:

1. Improved construction efficiency and time savings

aluminium slab formwork is characterized by its lightweight and high efficiency. It is easy and quick to assemble, significantly reducing construction time. Its sturdy structure and reusability allow construction teams to complete floor construction and concrete pouring more quickly.

2. Reduced labor costs and material waste

During slab formwork construction, there is no need for additional support systems, thus reducing the demand for labor resources. The durability and reusability of aluminium alloy materials help reduce the cost of replacing and repairing formwork.

3. Improved construction quality and stability

Formwork design for slab offers excellent anti-slip capability and stability, providing a safe construction platform for workers. Its sturdy structure and special connection methods ensure tight formwork assembly, reducing leakage and deformation during the concrete pouring process.

4. Comparison with timber formwork for concrete slab

Compared to traditional timber formwork for concrete slab, aluminium formwork for suspended slab has significant advantages. Traditional slab formwork often requires complicated installation and dismantling processes, while aluminium slab formwork adopts a quick assembly method, saving time and labor costs. Additionally, traditional slab formwork is prone to damage after multiple uses, requiring frequent replacement. In contrast, the durability and reusability of aluminium formwork for suspended slab make it more economically viable. It also provides higher safety and stability, effectively reducing the risk of accidents during the construction process.

● Knowledge

★ What supports slab formwork?

The slab formwork shuttering for the floor is set with 100mm beams, with a distance of 1300mm between each beam. Support rods are connected at the bottom of the beams for support, and the floor formwork is then laid flat on the beams in sequence and connected using dowels.

★ How long does formwork take to remove slabs?

The suspended slab formwork can typically be removed after 24 hours (Note: Early removal may result in concrete sticking to the formwork, affecting the quality of the floor). To ensure safety, the strength of the suspended slab formwork must reach at least 50% before removal operations can be carried out. Additionally, the timing of removing slab formwork is influenced by various factors, including season, temperature, construction environment, and cement grade. Therefore, the specific removal time needs to be determined based on the user's own construction characteristics. If users are uncertain or have any unclear points regarding the removal formwork time, they can contact us via WhatsApp. We will provide detailed construction plans and assist in resolving any queries, our commitment is to provide users with optimized services.

| Component Name | span(m) | strength of concrete(%) |

|---|---|---|

| slab formwork | ≤2 | ≥50 |

| >2,≤8 | ≥75 | |

| >8 | ≥100 | |

| Cantilever | - | ≥100 |

● Recommended

+86 19112905173

+86 19112905173