Metal Scaffolding

● what is metal scaffolding?

Metal Scaffolding is a temporary device made of metal pipes, used for support and erection during construction. Metal Scaffold is widely used in indoor and outdoor high-altitude operations in construction projects because of its stability, reliability, strong applicability, and easy installation.

● Metal scaffold types

There are many types of metal scaffolding,

According to the connection method, it can be divided into 3 types:

Coupler Scaffold

This type of metal scaffolding for sale is mostly used for exterior walls of indoor and low-height projectsRinglock Scaffolding

This type of metal scaffold for sale is reliable, convenient, mostly used in high-height projects.Cuplock Scaffolding

This type of metal frame scaffolding can work well with curves and is mostly used in bridges and cylindrical buildings.

According to the material, it can be divided into 3 types:

Steel Scaffold Automatic

Carbon Steel Scaffolding

Aluminum Alloy Scaffolding

● Metal scaffolding components

Crossbar

Crossbars are used to carry the weight of construction workers, tools, materials, and formwork.Vertical Pole

The vertical pole is the main supporting component of metal tech scaffold. It is connected to the horizontal pole through buckles to form a stable structure.Tie Rod

The diagonal tie rod is a rod in the metal scaffolding that ensures the stability of the structure.Hook Springboard

The hook springboard is strong, lightweight and easy to install and disassemble.

● metal scaffolding parts

90 degree scaffold coupler

coupler scaffolding parts

Scaffolding docking fasteners

ringlock scaffolding parts

scaffolding parts for cuplock

Top brackets and flat brackets

● Advantages and disadvantages of metal scaffolding

advantages of metal scaffolding

1. High safety: The metal frame scaffold has a solid structure, simple construction and high reliability. It is not prone to accidents such as tilting and collapse during use, and it can ensure the safety of workers.

2. Strong stability: The metal frame scaffolding will remain firm after being built and will not deform or tilt due to uneven force or external interference, providing safety guarantee for high-altitude operations. Therefore, it has become a commonly used climbing frame for high-altitude operations in construction projects.

3. High construction efficiency: The metal frame scaffolding is simple to set up and can be installed and disassembled quickly, thus saving a lot of time and labor costs. This can greatly improves the construction efficiency.

4. Strong load-bearing capacity: metal frame scaffold has a stronger load-bearing capacity than scaffolds made of other materials, such as wooden scaffolds. This is because steel is heavy-duty and hard. Metal frame scaffold can not only bear the weight of workers themselves, but also bear the weight of building materials and tools.

5. Corrosion resistance: The surface of metal frame system scaffolding is usually treated with anti-rust treatment, which greatly improves its anti-corrosion performance, That makes the service life of the scaffold longer and more durable.

6. Wide scope of application: metal frame scaffold is suitable for various construction scenarios such as construction, decoration, door and window installation, bridge maintenance, etc. Whether it is high-rise buildings in urban areas or infrastructure construction far away from the city, steel scaffolding can be wildly used.

1. Heavy weight: Because metal scaffolds are made of steel, whose weight is relatively large. This results in metal scaffolds requiring greater manpower and material investment during handling, installation and disassembly.

2. The cost of metal scaffolding rental is high: the manufacturing cost of metal formwork scaffold is relatively higher than wood scaffold, so for some small projects with limited budgets, this may increase the investment cost of the project.

3. Fasteners are easy to lose: metal formwork scaffold's fasteners (especially screws) are easy to lose, which may affect the integrity and stability of the scaffold. Additional measures are required to prevent loss of fasteners.

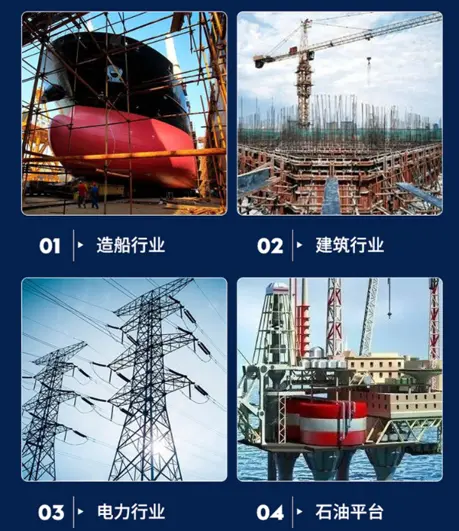

● Applications of metal scaffolds

1. Construction field: The metal scaffolding for construction can provide a stable working platform for construction workers and is widely used in new houses, decoration and demolition of houses.

2. Electric power industry: Electrical workers often need perform equipment maintenance and installation work at high places, metal tech scaffold platform can also provide them with a safe working platform.

3. Bridge construction: metal tech scaffold can be used for maintenance and construction of bridge. metal tech scaffold can provide a safe working environment and ensure the safety of workers to a certain extent.

● Assembling and disassembling of metal scaffolding

Steps of assembling of metal scaffolding (taking fastener scaffolding as an example)

1. Place the base: Place the metal scaffolding base at the preset position and level it with a level to ensure the stability of the base.

2. Construct the pole: Insert the metal scaffolding pole vertically into the base, maintain the specified spacing between adjacent metal scaffolding poles, and fix it with right-angle fasteners.

3. Install cross bars: Install large cross bars and small cross bars on the vertical pole according to the design elevation, and also use fasteners to fix them to form a stable frame structure.

4. Set up diagonal braces and scissor braces: In order to enhance the overall stability of the metal scaffold, it is necessary to set up diagonal braces or scissor braces and cross-fix them between two vertical poles.

5. Install the wall fittings: Firmly connect the wall fittings between the metal scaffold and the main structure of the building to prevent the metal scaffold from moving sideways.

6. Interlayer protection: After completing the construction of a certain number of layers of metal tech scaffold platform, interlayer protection facilities such as skirting boards, railings, and toeboards should be installed.

7. Comprehensive inspection and acceptance: After the overall installation of metal tech scaffold is completed, strict quality and safety inspections are required to confirm that all connection parts are fastened and reliable, and the overall structure is stable and meets the design and safety specifications.

Attention should be paid to the following during metal scaffolding construction:

1, metal scaffold boards should be placed accurately on the positioning line. The backing boards must be laid smoothly and must not be suspended in the air. When erecting columns, steel pipes with different outer diameters can not be mixed. The butt fasteners of adjacent columns must not be at the same height. The staggered distance should meet the structural requirements. When starting to erect the columns, a thrown brace should be set up every 6 spans. The wall parts should be installed stably, after that, you can do the disassembling of metal scaffolding according to the situation of your construction project.

2, When the metal tech scaffold is erected on the structural floor with connecting wall parts, the connecting wall parts should be installed immediately after the upright columns, longitudinal horizontal rods, and transverse horizontal rods are erected there. The longitudinal horizontal poles of metal tech scaffold must be circled on all sides and fixed to the inner and outer corner posts with right-angle fasteners. The distance between the end of the horizontal horizontal rod against the wall and the decorative surface of the wall should be less than 100mm.

3, When the metal scaffolding operating level is two steps higher than the connecting wall parts, temporary stabilization measures should be taken. After all the connecting wall parts are erected, disassembling of metal scaffolding can be carried out. Scissor braces and transverse braces should be erected simultaneously with columns, vertical and horizontal horizontal bars, etc. The distance between the center line of scissor braces, transverse braces and other fasteners and the main node should be less than 150mm.

● Metal scaffold safety precautions

1, Set up safety fences and warning signs: Set up safety fences and hang obvious warning signs at the job site to prevent unrelated personnel from entering the dangerous area.

2, Set up temporary supports or ties: For the metal formwork scaffold parts that have not yet formed or have lost structural stability, temporary supports or ties should be added in time to ensure their stability.

3, Use seat belts and safety ropes correctly: When using seat belts, make sure they are on a reliable safety belt buckle. If you cannot find a reliable safety belt buckle, you should set up a safety rope. Safety ropes should be securely fastened and their integrity checked regularly.

4, Safety facilities during the disassembling of metal scaffolding: When disassembling metal scaffolding, lifting or lifting facilities should be installed, and throwing materials is prohibited to prevent people and objects from falling.

5, Protective facilities: When the operation faces the outer facade, metal scaffolding boards plus two protective railings should be used, and a peripheral plastic woven cloth should be set (the height can not be less than 1.0m or set according to the step distance) to prevent people and objects from falling.

6, Strict operating specifications: The erection and dismantling of metal scaffolding must be carried out by trained professional scaffolders with certificates. Operators must strictly implement safety technical briefings and work arrangements before taking up the job. When the metal scaffold competent person leaves the working position, no rods to be fixed and unsafe hazards should not be left, you should ensure the stability of metal brackets for scaffold board fixtures. During the use of the scaffolding, it is strictly prohibited to dismantle the structural members without authorization. If dismantling is required, it must be reported to the technical person in charge for approval, and remedial measures should be implemented after determining the remedial measures.

+86 19112905173

+86 19112905173