30kw mini concrete pump machine

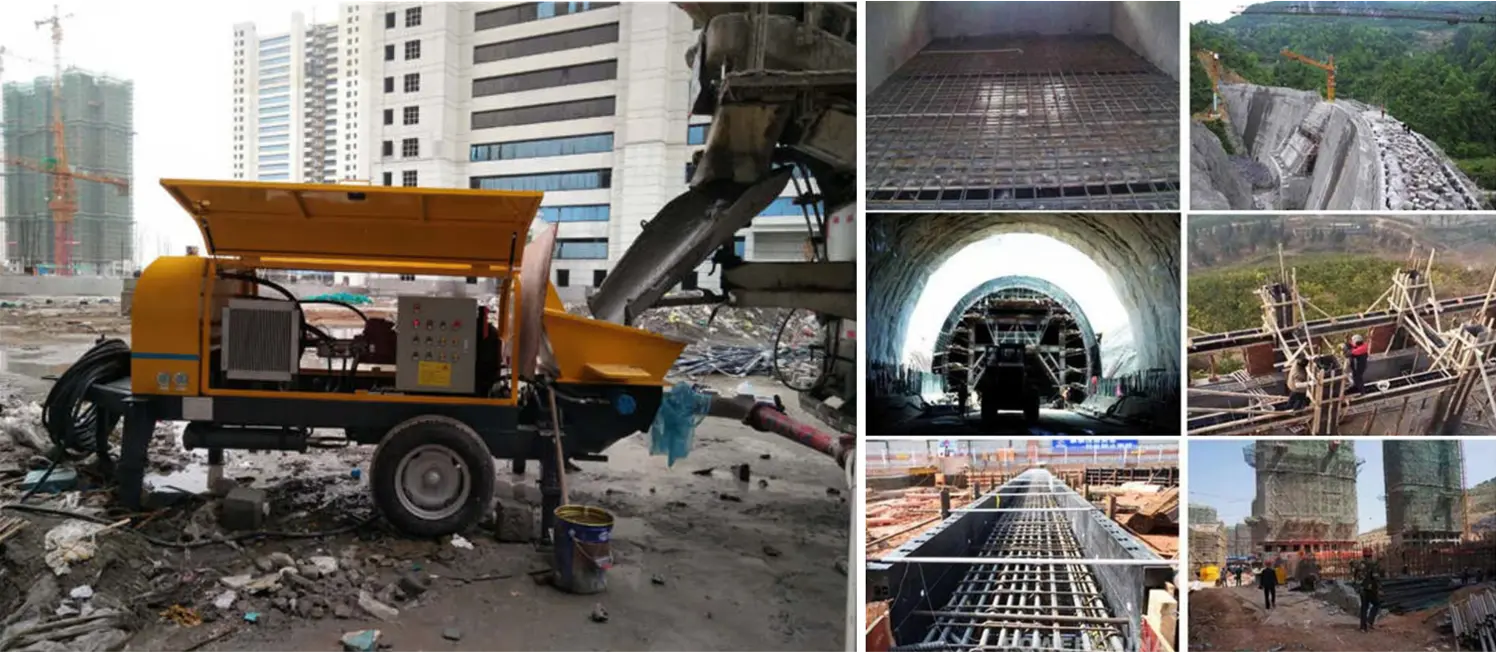

The mini concrete pump machine consists of pump and delivery pipes. It is a machine that uses pressure to continuously deliver concrete along the pipeline. It equips the steel pipes and soft pipes, and it can deliver the concrete to the remote, narrow construction site. The mini concrete pump machine for sale has wide applications in house building, bridge, and tunnel construction, it can reduce the construction costs and construction time. Our mini concrete pump for sale is loved by customers.

1. Pure copper motor

The mini concrete pump machine equips a powerful pure copper motor, it has stable performance and can continuously work in complex environments.2. Operation panel

Deliver speed, start, and stop of mini concrete pump machine for sale controlled by the operation panel and the operation is easy.3. Enlarge hopper

The mini concrete pump capacity is large and effectively prevents material spillage.4. Solenoid valve

The portable mini concrete pump adopts the solenoid valve and has the advantages of fast response, high precision, strong reliability, and easy operation. So, the delivery of the concrete is stable and accurate.

● Portable mini concrete pump specifications

| Maximum particle diameter | 3cm |

| Motor Power | 37kw |

| Conveying capacity | 15-20m3/h |

| Rated voltage | 380v |

| Horizontal conveying distance | 180m |

| Vertical conveying height | 80m |

| Size | 360*145*146cm |

| Weight | 2000kg |

| Maximum particle diameter | 3cm |

| Diesel engine power | 410 |

| Conveying capacity | 15-20m3/h |

| Delivery pipe diameter | 80-100-125mm |

| Horizontal conveying distance | 250m |

| Vertical conveying height | 120m |

| Size | 360*145*146cm |

| Weight | 2400kg |

Note: The mini portable concrete pump standard configuration is motor driven, and users can choose the diesel driven according to actual needs.

● Concrete pump advantages

1. Reduce construction cost

The portable mini concrete pump usually adopts a mechanical drive present. Compared with the traditional delivery method, the portable mini concrete pump has a powerful delivery capability and can reduce manpower and materials. It can continuous horizontal and vertical transportation to improve delivery capacity and reduce construction costs and times.

2. Good delivery capability

The mini concrete pump machine not only equips the steel pipes and soft pipes but also can add a placing boom to directly deliver the concrete. It can improve the delivery capability of mini concrete pump machine in the narrow construction site.

3. Complex usage environment

When the environment is bad, construction sites may face challenges such as muddy roads, making it difficult for vehicles to enter or workers to move around. The mini concrete pump machine for sale has big advantages for this condition. The mini concrete pump machine for sale can adopt longer delivery pipes to achieve long-distance delivery and can still be used for normal construction in harsh environments.

● Mini pump concrete applications

The mini pump concrete is a high efficiency delivery equipment and has the features of High-rise delivery and long-distance delivery. It has wide applications in various concrete projects, such as high-rise buildings, coal mines, mines, tunnels, railways and highways, bridges and culverts, ports, water conservancy, electric power, national defense projects, etc. The mini pump concrete pumping can not only deliver fine stone concrete but also deliver mortar for wall and slab construction.

● FAQ

How to choose mini concrete pump machine?

The mini concrete pump machine can be divided into electric mini concrete pump machine and diesel mini concrete pump machine according to different drivers.So, how to choose a suitable mini concrete pump machine according to your needs? YANSUMI as a professional mini concrete pump companies, we provide the following suggestion.

Take the model 30 electric mini concrete pumping machine as an example, this product adopts a 37kw pure copper motor and It can deliver aggregates less than 3 centimeters, 80 meters vertically, 180 meters horizontally, and 15 to 20 square meters per hour. Compared with diesel mini concrete pumping machine, the mini concrete pumping machine is more stable in operation, with a lower failure rate and lower usage costs. Additionally, the maintenance expenses are also relatively low. In general, the electric mini concrete pump cost is lower.

The model 30 diesel mini pump concrete pumping adopts the 4105 diesel engine, compared with electric mini pump concrete pumping, it has a larger power and has fewer limitations and no usage scenario restrictions. but the diesel mini pump concrete pumping cost is higher.

Therefore, if there are 3 phases of 380v power on the construction site, we can buy the electric mini concrete pump machine, the economic effect is better, otherwise buy diesel mini concrete pump machine.

How to use mini portable concrete pump?

The mini portable concrete pump is a normal delivery equipment for concrete, this mini portable concrete pump has wide application in high-rise buildings, tunnels, railways and roads, and dams. And popular with construction parties. However, how to use mini portable concrete pump?

1. Preparation

We should check the hydraulic gauge and working status of various parts before starting portable mini concrete pump.In general, the outlet of the portable mini concrete pump is prone to clogging. In case of a blockage, the machine should be in reverse rotation operation to allow the blocked concrete to flow back. Once it is evenly mixed, it can be delivered again. If there is no improvement, the machine should be stopped and the blockage cleared.

2. Using

During delivery of the concrete, the concrete should be continuously supplied, we should slow the delivery speed of concrete if can not be continuously supplied. The concrete pump mini can not allow stop working if the concrete supply disconnects. It should be rotated forward and reversed operational every 4-5 minutes to prevent the mixture from clumping or settling in the pipeline. If it is stopped for more than 45 minutes, it should be cleaned before delivering again.

During delivery of the concrete, keep a certain amount of concrete in the hopper to prevent the air into the pipes and causing the concrete to flow back and form blockage. If happen this problem, The concrete pump mini needs to be reversed operational so that the concrete returns to the hopper, and normal delivery can be carried out after the air has gone out.

During vertical delivery of the concrete, the water hammer will cause a reverse flow of concrete and reduce the conveying efficiency. The higher the conveying height, the more obvious the phenomenon will be. For this problem, we can set up a horizontal pipe of more than 10 meters between concrete mini pump and a vertical pipe to reduce the influence of the concrete falling and install the check valve in the discharge port. In addition, we should pay attention to protection from sunlight and spray water regularly to prevent the blockage of pipes during construction at high temperatures.

YANSUMI is a manufacturer specializing in the development, production, and sales of mini concrete pump machine. With our strong capabilities, competitive mini trailer concrete pump price, reliable product quality, and comprehensive service support system, our company has won unanimous praise from customers.

+86 19112905173

+86 19112905173