Mini Concrete Pump

mini concrete pump, also known as secondary construction pump, concrete pump, etc., is a mechanical equipment composed of a pump body and pipeline. It uses pressure to continuously transport concrete along the pipeline. It is mainly used for the construction of building structures, underfloor heating insulation, flooring, cushion layers, module casting, bridge and tunnel construction, etc.

● Specifications

| Allowable delivery particle size | 1-2cm |

| Vertical conveying distance | 20m |

| required power cord | 6 square national standard 3+1 |

| Operation method | remote or manual |

| Total Weight | 500kg |

| Machine size | 200X 700X 1200mm |

| machine layout | horizontal |

| Standard pump tube | Iron pipe + hose |

| Horizontal conveying distance | 40m |

| Pump pipe diameter | 75mm |

| mini concrete pump capacity | Theoretical flow 8.5 square meters |

| Motor Power | 7.5KW |

| way of walking | Electric |

| Feeding method | Pumpable and suctionable |

● Features

1. mini pump concrete pumping is easy to operate, convenient and quick, with an efficiency hundreds of times higher than that of manual pouring, reducing construction time and labor costs.

2. It is easy to move, with stable performance, compact structure, high configuration, low failure rate and long service life, good conveying continuity and high pressure.

3. portable mini concrete pump has a far conveying distance and high elevation, and can directly pour on the floor, effectively improving work efficiency.

4. The powerful diesel power is used for the transportation of concrete in high-rise buildings, with high working pressure, large displacement, and low failure rate.

Control Panel

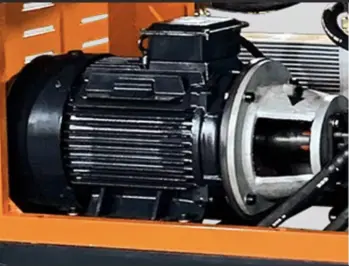

One-key start, simple operation, Easy to master, efficient and convenient.High-power Motor

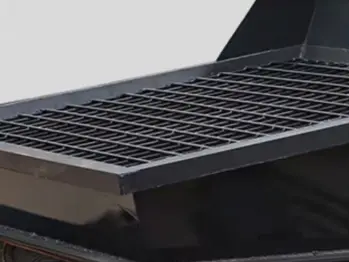

Pure copper motor with strong power, Stable performance, durable and long-lastingEnlarge Feeding Hopper

Enlarging and widening the feeding hopper improves efficiency, the baffle screen prevents material blockage.

High Outlet Pressure

Meets the requirements of high-rise building and long-distance construction conveying.

Four legs are used to fix it during operation, stable and reliable.

● mini concrete pump machine

How to handle the concrete components of different grades when pouring with mini concrete pump truck?

1,When conveying concrete with mini concrete pump truck for sale, it should be poured from far to near.

2,For concrete in the same area, it should be poured layer by layer according to the order of first vertical structure and then horizontal structure.

3,When the strength grade of column or shear wall concrete is higher than that of beam concrete, the concrete at the beam-column junction should be poured according to the strength grade of the column or shear wall concrete. At this time, the high-grade concrete of the column should be poured first, and then the low-grade concrete of the beam should be poured. Simultaneous pouring is also possible, but special attention should be paid to ensure that the low-grade concrete does not spread to the structural parts of the high-grade concrete, so as to ensure the structural quality of the high-strength concrete.

"How to maintain mini concrete pump machine for sale?

During the use and storage of mini concrete pump machine, due to mechanical wear, natural corrosion, and aging, its technical performance will gradually deteriorate, and maintenance and repair must be carried out in a timely manner. The purpose of maintaining mini concrete pump machine is to restore its normal technical state, maintain good performance and reliability, extend its service life, reduce oil and equipment consumption, prevent accidents, ensure driving and operation, and improve economic and social benefits. Here are some maintenance and maintenance methods for small concrete conveying pumps.

Cleaning

Ensure that the machine is clean, the engine and all assemblies and accompanying tools are free of dirt, all filters are used normally, and the hydraulic oil and pipelines are unblocked.

Inspection

Check whether the engine and all assemblies and components are in normal state. The components should be complete and reliable and whether the connection and fasteners are intact.

Fastening

All fasteners must be complete and undamaged, and the installation must be secure, and the tightening degree should meet the requirements.

Adjustment

Familiar with the technical requirements of the adjustment of each component, and carefully adjust according to the method and steps of adjustment.

Lubrication

Select lubricants correctly according to different regions and seasons. The oil and tools added should be clean. The filling port and oil nozzle should be wiped clean, and the filling amount should meet the requirements.

When operating mini concrete pump, what issues should be paid attention to?

During the construction process, it is important to follow the operating rules of mini concrete pump companies to ensure construction safety. So what should be noted during the operation of a concrete conveying pump? This is a question that many construction parties are very concerned about.

Firstly, it should be ensured that the pipeline of mini concrete pump is firmly supported, and the connection of each joint should be firm. Pressure or heavy objects should not be added above the pipeline, otherwise the conveying pipeline may be damaged.

Before use, check the working status of the electrical equipment of mini concrete pump, whether the instruments work normally, and whether the hopper filter screen and safety protection device are normal. During the concrete pumping process, pay attention to whether the pressure gauge indication is normal. If the machine stops due to a malfunction, open the bleed valve to release the pressure and eliminate the malfunction. When the pressure has not reached zero, do not disassemble the air chamber, pressure valve and pipeline to prevent danger.

In addition, if mini concrete pump generates heat due to the hydraulic system during use, it must be given sufficient attention by the operators, because the phenomenon of heat generation often causes many malfunctions. From the perspective of the manufacturer, prevention should be implemented starting from the design stage, reducing the heat generated by its hydraulic system to a lower value, and improving the service life of mini concrete pump.

If you want to buy machines for construction, such as motorized wheelbarrows,concrete screed machine, track barrows,concrete power screed, concrete mixers, you can contact us.

+86 19112905173

+86 19112905173