The purchase process of aluminium formwork

● What is aluminium formwork?

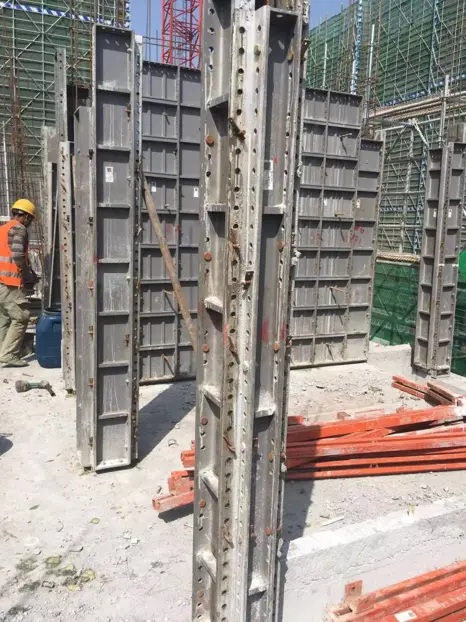

Aluminum formwork is a formwork which is suitable for concrete projects. It takes aluminum alloy profiles as main material and made through mechanical processing, welding and other processes. Aluminum formwork can make concrete structures and components to be cast according to the geometric dimensions and positions required by the design, and ensure that the shape, size and mutual position of the concrete structure or components are accurate.

How to successfully purchase aluminium formworks that meet your design requirements? We will make a detailed introduction as below.

● Purchase process of aluminium formwork

Step 1. Provide structural drawings of your project

Each project has its own features. In order to make an aluminium formwork construction plan that is completely suitable for your specific project, we need you to provide structural drawings which is as complete and accurate as possible in addition to introduce the specific conditions of the project, so that we can analyze that whether your project can be constructed with aluminium formwork and how to use the aluminium formwork in construction.

Step 2. Calculate the approximate quantity of the aluminium formwork

We are an experienced aluminium formwork manufacturers. Based on your project structure drawings, we will calculate the approximate aluminium formwork square meters which is required for the project according to our experience. It should be noted that this square meters value is not fixed. It is variable because it will be affected by many factors such as different construction methods, construction progress requirements, etc.,. The finally value will be counted after the latest design is determined.

Step 3. Quote aluminium formwork price preliminary

At this stage, we will quote you the price of aluminium formwork per square meter. If you have interest in visiting our factory, we will be very happy. And if you want to visit our aluminium formwork construction site, we can also arrange it, and this process may have some costs which will be calculated based on the exactly situation.

Step 4. Confirm the aluminium formwork price

At this step, we will confirm the finally price of aluminium formwork per square meter with you. And we will design an economical and suitable aluminium formwork construction proposal for you combine your requirements after you pay a certain amount (approximately few thousands dollars). This is because a truly feasible solution proposal need to do a lot of complicated and meticulous jobs on the aluminium formwork design calculation, this needs to be carried out by our professional design team. But please don’t worry, this money will be deducted from the balance of your purchase amount of our aluminium formwork.

In the aluminium formwork design proposal, we will do our best to make the aluminium formwork to have the strongest versatility, so that you can greatly reuse this batch of aluminium formwork into current project and other new projects in the future as much as possible, to save you investment and construction costs. With this design plan, you will see the specific details such as which construction areas require aluminium formwork, how many and what types of aluminium formwork will be used, etc.

It should be noted that in order to maximize the utilization rate of aluminum formwork, we need to communicate with your project manager responsible for executing the construction plan. Only in this way, the aluminum formwork construction plan can be the lowest cost, most economical and applicable for you.

Step 5. Pay the deposit and start the aluminium formwork manufacturing process

According to the aluminium formwork construction plan which determined by both parties, we will calculate the final quantity of aluminium formwork required for the complete project, combined with the fixed unit price of aluminium formwork, get the total amount of the aluminium formwork, and sign a sales contract. At this time you will pay a certain percentage of the amount as a deposit (usually 30% of the total amount), and then we will officially start the aluminium formwork manufacturing process after receiving the deposit.

Step 6. Pay the balance and assemble the aluminium formwork in China

After we finish the production of the aluminium formwork, your company will pay the balance. Then we will assemble the aluminium formwork and do aluminium formwork modification accordingly in China, to ensure that the aluminium formwork parts you receive can be assembled and used smoothly.

We will number each aluminium formwork panels carefully according to the updated drawing, and will provide you with a management system. With this system, you can check the aluminium formwork details such as specifications, quantity and application position by entering the number or scanning the QR code, so that you can easily know the usage of the aluminium formwork, and it is very helpful for aluminium formwork installation, and also can improve your construction efficiency and management efficiency.

Aluminium wall formwork provides support for the pouring of concrete walls.

Step 7. Aluminium formwork shipping

After finish the debugging of the aluminium formwork, the party will contact the freight forwarding company for shipment according to the negotiated trade terms.

Step 8. Guide the aluminium formwork installation

After you receive the aluminium formwork, we can send people to your location to provide installation guidance for the aluminium formwork as needed, or train technical workers for you to help you master the installation and use of the aluminium formwork.

At this time, the complete aluminium formwork transaction process is finished. Of course, if you have any questions during the use of the aluminium formwork, please feel free to contact us, we will provide you with corresponding aluminium formwork construction technology supportation. You don’t need to worry.

● Advantages of aluminium formwork

● Aluminium formwork has strong bearing capacity. Our aluminium formwork panels have high strength, stiffness and stability. It can reliably withstand the weight of poured concrete, lateral pressure and other construction loads, ensuring that there will be no serious deformation, overturning or instability.

● Aluminium formwork system has high construction speed and short construction period, generally can complete one floor in 3-5 days;

● Aluminium formwork can be reused many times (more than 300 times, depend on actually construction status);

● Aluminium is convenient construction. The aluminium formwork weight is light, this making it easy to transport. The aluminium formwork installation and disassembly is also very simple, making construction very convenient.

● Aluminium formwork has wide application range. It can use for the construction of residential, apartment, commercial, bridge, tunnel and other more concrete projects.

Based on the aluminium formwork advantages, it is more and more favored by contractors in the construction industry.

We are an aluminium formwork manufacturers that integrates R & D, design, production, sales, installation, and maintenance, we have professional teams and with rich experience, we provide high quality and comprehensive service to customers. We supply complete aluminium formwork panels, aluminium formwork accessories, aluminium formwork components, and aluminium formwork parts. Our aluminium formwork system has been widely used by large domestic construction companies such as China Communications Construction Company, China State Construction Engineering Corporation, Vanke, and Poly, and it also been used in construction projects in many other countries. If you hope to improve the construction efficiency and effect of your project and save construction costs, please contact us for more detailed communication.

+86 19112905173

+86 19112905173