Aluminium formwork manufacturer

We provide our clients with comprehensive services from aluminium formwork design to aluminium formwork construction. As a supply chain enterprise for multiple real estate developers, it seamlessly connects with developers from material supply, technology optimization to construction guidance.

● Our advantage

◆ Welcome to Hebei to visit our factory.

◆ Large production scale, advanced equipment and perfect management system

◆ Rich design and production experience, strong comprehensive strength

◆ Professional export capabilities and rich experience

◆ High quality aluminum material, sturdy and durable, long service life

◆ Professional R & D team, advanced technical support

◆ Various domestic qualification certificates and CE certification, quality guaranteed

◆ Provide technical support and professionals to assist in solving problems during construction

◆ Worry-free installation, personnel can be dispatched to help you train workers

◆ Multiple purchasing options to meet the needs of users with different budgets

◆ Design aluminum formwork drawings and plans according to users' specific projects

◆ Most standard formwork can be reused for multiple projects, suitable for small projects too

◆ Scientific formwork management system, high construction efficiency and management efficiency

◆ Formwork data comparison function provides basis for secondary purchases

◆ Light and compact, low labor intensity

◆ Easy to install and disassemble, low construction difficulty

◆ Fixing system, quality controllable, weak reliance on worker skills

◆ Low requirements for construction personnel, only simple training is required

◆ Simple support structure, easy access for personnel and materials, safer construction

◆ Anti-corrosion and anti-rust, high reusability, can be reused more than 300 times

◆ Various specifications, modular combination into required size

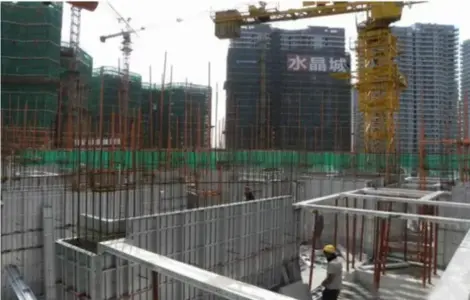

◆ Suitable for various projects such as residences, apartments, commercial centers, bridges, tunnels, pipe corridors, etc.

◆ Wide construction range, suitable for walls, columns, floors, beams, stairs, windowsills, floating boards, etc.

◆ Strong bearing capacity, no deformation, no mold expansion, no mold explosion

◆ Good poured structure, no gaps or deformations

◆ Flat and smooth poured structure surface, improving the quality of your construction

◆ No need for leveling and plastering, low decoration cost

◆ Concrete is poured more evenly and tightly, structure is no water leakage

◆ Fast construction progress, short construction period

◆ Manual transfer of formwork, no tower crane required

◆ Good fire resistance, safer construction

◆ Convenient and simple disassembly, no lifting equipment required

◆ No sticking to concrete, no damage to structural surfaces during disassembly

◆ Easy to clean and easy to recycle during project construction

◆ Safe and hygienic construction site after formwork removal

◆ Less construction waste, convenient and quick on-site cleanup

◆ Recyclable, no environmental pollution

◆ Simple maintenance, less repairs and low losses.

◆ Less labor, saving management and labor costs

◆ Low comprehensive construction cost

◆ One-time investment, long-term profits

◆ Excellent construction effects can better establish your brand image and reputation

◆ High construction efficiency makes your company more competitive

◆ Not only can use it yourself, but also can rent out to share the cost and create profits

◆ Can be used for mortgage loans and financing when necessary

◆ An indispensable tool for modern building construction

◆ Improve construction quality and promote the development of the construction industry

◆ Harmoniously build a better and livable future city

● Our aluminium formwork system project The purchase process of aluminium formwork

Cheng Ji Xin Yuan Aluminium Concrete Formwork Systems Project

Commerce Building Concrete Formwork Aluminium Project

Tian Xiwan Aluminium concrete formwork panels project

Feicui Jun Aluminium Concrete Formwork Scheme

Weilaicheng aluminium concrete formwork design project

Vanke City Aluminium Concrete Formwork Hire Solution

Jinse Jiayuan concrete formwork materials Project

As a professional formwork manufacturers,our company is equipped with advanced aluminium extrusion equipment,aluminium punching machine, and complete quality inspection equipment domestically and internationally. We have established a sound ISO quality management and quality assurance system, together with a sophisticated production management software system and the most advanced and powerful aluminium formwork design software system in the industry, ensuring that our products are of the highest quality and leading level in the industry.

Our formwork products for sale have both competitive pricing and quality advantages, which is why many foreign the formwork company have also purchased from us, such as Aluminium formwork manufacturer in Pune, Aluminium formwork manufacturer in India, aluminium windows manufacturers in chennai, and have received positive feedback from customers. At the same time, our products such as aluminium formwork in India, Pune, Chennai, USA, Korea, Malaysia, Singapore, Australia, and other markets have also been well received by users.

Our company use the latest domestic technology and equipment, including new extrusion, vertical spraying, imported deep processing sawing and punching machines, as well as the internationally recognized 7S management system. This approach has significantly improved our labor productivity and asset utilization efficiency, and strengthened our competitiveness in both domestic and international markets.

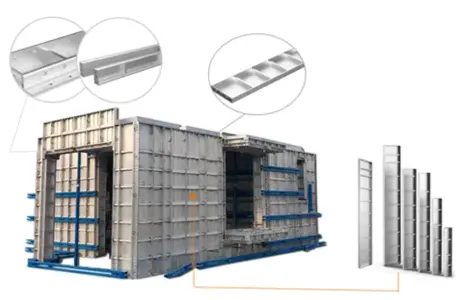

● What is aluminium formwork

Aluminium formwork is a new generation of formworks systems following wood formwork, plastic formwork, and steel formwork. The shuttering material is aluminum alloy profiles and is processed through mechanical machining and welding to create panel formwork suitable for concrete engineering. The formwork is made up of panels, ribs, main profiles, flat formwork, corner formwork, and early disassembly devices. Aluminium formwork design and aluminium formwork construction represent a revolution in formworks technology for concrete engineering and a reflection of the industrialization of construction technology.

The aluminium formwork system consists of four parts: slab formwork system, wall formwork system, beam formwork system, and accessory system. It is suitable for various structural forms such as high-rise buildings, residential areas, bridges, tunnels, etc. The advantages of formwork for sale lie in its flexibility and efficiency, greatly improving construction speed and quality, while reducing construction costs.

● Advantages of aluminum formwork:

1. Lightweight and high strength: shuttering material is made of aluminum alloy, which has a lower density and higher strength, making it lightweight and rigid. Compared to plastic formworks and steel shuttering, shuttering material is more lightweight and easy to transport and install, reducing the labor intensity of workers.

2.Easy processing and assembly: Aluminum formwork can be customized and processed according to specific requirements, adapting to different building structures and shapes. Its modular design and connection system make the aluminium formwork construction process more convenient and efficient, improving construction efficiency.

3. High efficiency and energy-saving: aluminium shuttering has excellent thermal conductivity, allowing heat to be quickly and evenly conducted, resulting in more uniform concrete solidification. Additionally, the smooth surface of aluminium shuttering reduces friction between the concrete and panel formwork, minimizing damage to the concrete during formwork removal and increasing the reusability of system formwork.

4. Durable and reliable: alu formwork exhibits excellent corrosion resistance and mechanical properties, allowing it to withstand heavy loads. It has a long service life and, with proper maintenance, can be used repeatedly, reducing construction costs.

5. Safe and environmentally friendly: aluminium system formwork uses non-toxic and environmentally friendly materials that do not have harmful effects on construction workers or the environment. The surface coating and anti-corrosion treatment enhance the fire resistance and weatherability of the formwork, providing higher construction safety.

6. Aesthetic effect: The surface of aluminium formwork panels is smooth and even, eliminating the need for additional painting or decoration. It can be directly used for concrete pouring, resulting in a consistent, smooth, and aesthetically pleasing appearance of the building surface.

In summary, aluminum formwork is widely used in the construction of various building structures and concrete pouring due to its advantages such as lightweight and high strength, easy processing and assembly, high efficiency and energy-saving, durability and reliability, safety and environmental protection, and aesthetic effect. As a result, it brings many conveniences and economic benefits to the construction industry.

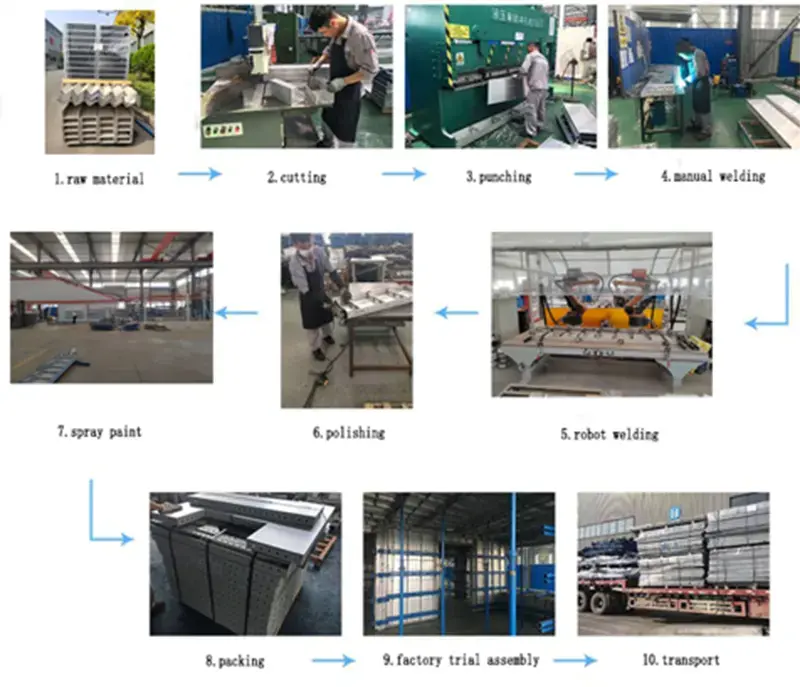

● production process

● After-sales service

Technical Services

Shengzuo Aluminium formwork manufacturer provide professional installation guidance services, including training for installation workers, technical briefing, and on-site guidance. We actively assist installation personnel in solving difficult problems during aluminium formwork construction.secondary matching services

We have established a standardized aluminium formwork system, in which 80% of the formwork for sale is standard version and 20% is non-standard version. We provide secondary matching services, which can provide convenient services for the next use of 80% standard formwork for sale.Old Formwork Recycling

Shengzuo formwork manufacturers provide services such as old-for-new replacement, formwork refurbishment, and formwork recycling.

+86 19112905173

+86 19112905173

Aluminum formwork price

Aluminum formwork price  How to buy aluminum formwork ?

How to buy aluminum formwork ? Aluminum formwork construction video

Aluminum formwork construction video Aluminium formwork VS Steel formwork

Aluminium formwork VS Steel formwork