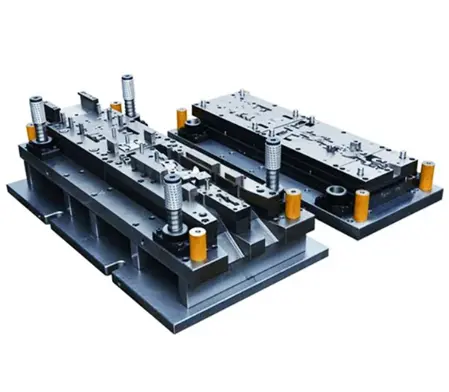

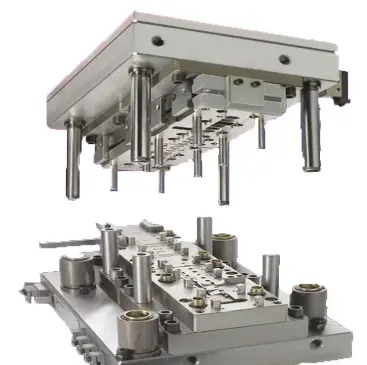

Drawing Die

What is drawing die?

Drawing die is a tool usually used to help metal shaping processing. Its main function is to stretch the metal sheets or bar steel to make metal parts with various shapes and sizes.

Drawing die is made of many parts, including die set, side plate, guidepost , drawing column, pressing plate, drawing block, upper die, lower die, locating pin and spring . The upper formwork and lower formwork of drawing die is respectively to press and draw. The drawing stick is used to press the materials into required shapes. The locating column and guide sleeve are used to ensure the precision and stability of dies. The drawing block is the core of metal drawing die. The design of its size and structure can determine the size, shape and quality of formed parts. The shapes and quantities of drawing block depend on the needs. The common ones are single stage drawing die and multi stage drawing die.

● parameters of extrusion die drawing

| Regular shape drawing die | Type10 | 25×12 28×16) | 0.25~0.8 | for drawing black non-ferrous metal wire rod |

| Type11 | 28~40×12~28) | 0.4~5.7 | for drawing ferrous metal wire rod | |

| Type12 | 25~50×1028 | 0.4~8.0 | for drawing non-ferrous metal wire rod | |

| Type13 | 66~220×35~80 | 3.7~84.0 | For drawing black non-ferrous metal steel bar | |

| Type S11 | 28~40×12~28 | 0.4~5.7 | Large compressed angle die for drawing non-ferrous metal wire rod | |

| TypeS13 | 66~220×35~80 | 3.7~ 84.0 | Large compressed angle die for drawing ferrous metal wire rod and steel bar | |

| TypeW1 | 24~230×12~90 | 0.5~55.0 | Large entrance angle die for drawing ferrous metal wire rod | |

| Type20 | 32~ 190×22~75 | 2.0~60.0 | Thick-walled pipe die | |

| Type21 | 98~190×55~70 | 20.0~62.0 | Thick-walled pipe die | |

| Type22 | 45~ 220×25~75 | 3.0~90.0 | drawing ferrous metal pipe die | |

| Type23 | 98~200×55~75 | 20.0~ 70.0 | Dual purpose dies for pipe diameter and wall reduction | |

| Irregular shape drawing die | Type40 | 33~200×20~70) | 1.8~55 | For drawing square steel bars |

| Type41 | 40~135×20~ 35 | 1.9~32.0×1.0~6.5 | Drawing rectangular material die | |

| Type42 | 25~50×1028 | 0.4~8.0 | for drawing non-ferrous metal wire rod | |

| Type60 | 66~ 200×30~ 70 | 2.5~ 75.0 | Drawing hexagonal material die |

| Drawing the tube core | Type30 | 28~64×27~ 35 | 17~ 28 | Drawing dies for seamless steel pipes |

| Type31 | 14~47×25~45 | 7~ 26.4/td> | Drawing dies for seamless steel pipes | |

| round and straight coating die | QN4710~ QN4716 | 8.5×12 10.5×12 | 3.2~5.5 | For producing electrodes |

| QN105~ QN1033 | 15×20 | 1.5~7.0 | ||

| Drawing the tube core | Flat head die | Cold heading and cold punching of copper, aluminium, alloy steel, wire earwig, Mao, etc. | ||

| Countersunk head die | ||||

| Flaying die | Type QCI | Medium3.0~p30,0 | For stripping ferrous and non-ferrous wires and tubes before drawing | |

| Type QC2 | p32.8~w50.0 | |||

| Wire feeder flywheel | p136 p150 p160 | For producing electrodes |

● drawing dies types

There are many drawing dies types. We can classify them according to different standards.

1,by process:

a)first drawing die: use flat blank materials.

b)Subsequent processing drawing die: use semi-finished tube workpiece which has been drawn.

2,by functions:

a) ironing die: the change of tension piece diameter is small. During the drawing process, the thickness of the bottom of work piece will not change, and the side wall thickness will go thin and the height will increase like deep drawing die. Die of deep drawing need to make deeper depression area to ensure that metal sheets can be stretched completely. To make sure the precision and quality of die, this kind of die usually use high precision technology and device to design and produce, such as CAD, CAM, CAE.

b) reverse redrawing dies: its working principle is to turn the inside of workpiece out, so that the contact surface between workpiece and concave die will be big.

3, by processing directions:

a) single directional drawing die: stretch the metal sheets into processing die with certain shapes in a certain direction. It is suitable for producing vortical and symmetrical parts, such as metal shells and lids.

b) Multidirectional drawing die: it can stretch metal sheets into complex shapes in multiple directions. It is suitable for producing various metal parts with complex shapes, such as car body and airplane casing.

4, by shapes:

a) ball drawing die: it’s used to make ball or ball cap formed parts.

b) pipe drawing die: it’s used to make pipes with various shapes, such as square pipes and round pipes.

5, by materials:

a) wire drawing die: it can draw various types of non-ferrous metals and steel like die for wire drawing.

b) pipe drawing die: it can draw various types of non-ferrous metal pipes and steel pipes.

c) special shaped material drawing die: it is used to draw special shaped or irregular shaped materials like conical drawing die.

In the metal processing industry, deep drawing is an essential craft. It involves a special used die called Deep drawing die, which can make metal products with deep cavities and complex shapes. Design of deep drawing dies and deep drawing die material are very important to ensure product quality and efficiency.Let’s learn some terminologies about deep drawing die.

Drawing die angle usually refers to the bevel angle used to draw metal in the die. It determines the flow direction and speed of metal, directly influencing the product’s quality and the shaping effect.

Drawing die box refers to the main body of deep drawing die. It contains metal sheets and stretch them into required shapes in the punching process.

Deep drawing die clearance refers to the space used for the flow of metal sheets in the die. The area of this gap needs to be designed by the nature of materials and the precision of the desired products.

Deep drawing die design involves the whole structural design of the die, including the shapes of the die, the choice of materials, hot treatment craft, etc. It aims to make sure the die work efficiently and stably.

Drawing die holder is a device to fix and support the deep drawing die. It ensures the dies maintain stable location and shape in the punching process.

Drawing die radius refers to the fillet radius used to draw metal in the die. The size of this radius will greatly influence the quality of products, the service life of die and the uniformity of metal flow.

Die drawing ratio refers to the deformation degree of metal sheets in the drawing process. It is one of the important indicators to evaluate the performance of die and the reasonableness of products design.

We are deep drawing die manufacturer. We can customize and produce dies according to the requirements of clients and specifications of products. We have special deep drawing die design software, which can simulate the flow and deformation of materials. It can help engineers make deep drawing die design precisely and improve processing efficiency and products quality. If you need to buy dies, please contact us at any time. We can provide you with excellent dies, machines and metal forming solutions.

● drawing die process application

Drawing die is a kind of punching die, usually used in deep drawing process in metal punching. It can stretch flat metal materials into deeper shapes. Different drawing dies types are used in different areas.It is also widely used in production of precise parts, such as tubes, bushings, ball shells, nozzles, etc. Meanwhile, cold drawing die is also widely used in the production of cars, motors, electrical machinery, boilers and other mechanical equipment, to produce various types of metal products, such as metal cover, metal barrels and barrel covers, car doors, trunk covers, shells and various household appliances shells, etc.

● drawing die process

drawing die is mainly used in the drawing of metal sheets. In this process, you should go through the following steps:

1, Dies installation: you should fix the drawing dies on the lower die surface of press machine first, and then adjust the die according to the sizes and shapes of required products.

2, Sheets assembly: put the metal sheets to be processed into the die through the upper die surface. If the sheets don’t keep flat and completely contact with dies, they will deform or form incompletely.

3, Drawing process: drawing die will put pressure on the paint surface, so that the sheets can draw the convex parts to make deformation, completing the deep drawing process.

4, Convex forming: the depth of drawing has been limited by controlling the processing depth of the inner drawing die , and the local sheets need to be formed by the convex parts expansion.

5, Product demoulding: after the forming, you can divide the metal parts and drawing die by mechanical system.

+86 19112905173

+86 19112905173