Pipe Bending Die

pipe bending die price:400usd---2500usd

Pipe bending die (tube bending die) is a special tool for bending pipes, usually used to make various pipe parts and connecting parts. This bend die tooling is widely applied in machinery processing industry.

Pipe bending die set is usually made of good alloy steel structural steel materials, having high stability and long service life. Die body is the main part of the whole pipe bending die,playing the primary role of carrying, supporting, and bending forces transmission.

● The working principle of pipe bending die

The principle of pipe bending die design is very simple: bend the metal materials into required shapes by machine pressure. In practical operation, put the metal pipe on the working platform of pipe bending die, and adjust the direction of working platform as required to bend the metal pipes flexibly. When the metal pipe arrives at required angle, push the switch to the front to turn on the pipe bending motor, run the motor to drive the die core and the die body to bend the metal pipe at a certain angle.

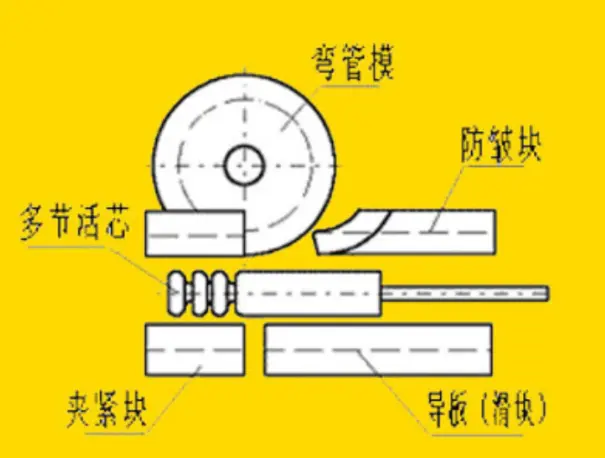

● The basic structure of pipe bending die set

Pipe bending die set mainly consists of 5 parts:

1. bending die.

2. clamp die.

3. pressure die ( to press the pipes and help to push the pipes to bend).

4. mandril (the shape of mandrills is various, it mainly used to support and then control the deformation and quality of the bent part of pipes).

5. anti-wrinkle block (to support pipes and prevent them from wrinkling).

When pipe bending dies are working, bending die process is: put the core into mandril, then the clamp die grips the pipes turning with the bending die. The pressure die will press the pipe and follow with the pipe bending, and the anti-wrinkle block is fixed, When the bending angle reaches the required angle, the mandril is withdrawn, and the pressure die and clamp die are loosened and returned to complete the whole action.

● Features of tube bending die for sale

-

Resistance to corrosion

Our tube bending die adopts professional lubrication way to make it have high resistance to corrosion. -

Tube bending die material is strong and durable.

Our bending die material is hard and durable, ensuring the good quality of surface. -

Save the consumption

Due to the bending die design calculation, the friction coefficient of our die is low, and the drawing electric consumption can be reduced.

● The parameter of bending die set

| bending machine diename | round tube bending die |

| tube bending die material | copper alloy(customizable) |

| die type | forming die |

| function of bending die | to bend. |

| die core processing | Process the core |

| specifications of bending materials | 38/50/75/89/168 |

● Bending die types

Bending die types are variously. According to different classification standards, they can be categorized as follows:

1. Classification by shape:

● V bending die: V bending die mainly used for V-shaped bending processing for the tubes, plates, etc. The cross section is like shape v. Both sides are 45 degrees angle, you can get relatively uniform bending angle when it is applied to bending materials.

● U bending die: U bending die is suitable for U-shaped bending, its cross section is like shape u. Both sides are 90 degrees, it’s helpful to prevent the workpieces from drifting to two sides.

● Round bending die: The cross section is arc-shaped, used for workpieces with small bending radius. You can choose the degrees of arc according to the bending radius of workpieces.

● Cone bending die: It is used for the processing of concavo-convex workpieces, usually divide into inner cone die and outer cone die.

2. Classification by structure:

● Single station die: Complete the whole forming process in one operation.

● Dual station die and multi-station die: Complete different forming processes at multiple stations, improving production efficiency.

3. Classification by use:

Bending die can be divided into square tube bending die, round tube bending die, rebar bending die, wire bending die, sheet metal bending die, etc.

● Bending die uses applications

Pipe bend die is a machinery parts with high accuracy, it is used for the forming processing of metal pipes. This die of bending is widely applied in the fields such as vehicle manufacturing, machinery and equipment, household supplies, etc. Tube bend die is used to complete pipes bending processing. Its main uses include the following aspects:

1. Precise pipe bending processing: With the improvement of pipe bending dies manufacturers technology, bend dies can achieve highly precise pipe bending processing, meeting the bending accuracy requirements of industrial productsfields, such as aviation, manufacturing, construction, etc., it can also be used in home decoration and other fields.

2. Improve working efficiency: Normal pipe bending craft wastes time and energy and is easy to make mistakes, while pipe bending dies for sale can complete large scale pipe bending processing in short time, having advantages both in working efficiency and quality.

3. Save labor costs: Using pipe bending dies can efficiently reduce the demand of labor force, and make workers work easier. And it can improve the production efficiency and quality of production line.

4. Wide range of applications: Sheet bending die and tube bend die are widely used in all walks of life, not only can be used in a variety of industrial fields, such as aviation, manufacturing, construction, etc., but can also be used in home decoration and other fields.

● How to choose pipe bending dies for hydraulic press and the size of round pipe external diameter?

1. Choose suitable pipe bend die

● Learn about types of pipe bend die

Pipe bend die includes fixed die, left-right moving die, lifting die, adjusting die and pushing back die, etc. Different types of dies are apply to different types of round pipes processing.

● Choose dies according to the processing requirements

When choosing pipe bending dies, you should rely on processing requirements and round pipe materials. If you need to bend small round pipes, you can choose lifting die or pushing back die. While for large size round pipes, you need to choose fixed die or left-right moving die.

● Consider the quality and durability of pipe bending dies

When choosing dies, please pay attention to its quality and durability. Good pipe bending dies should have high hardness, high strength and durability.

2. Choose suitable round pipe external diameter size

● The relationship between round pipe external diameter and bending radius

When bending round pipes, the round pipe external diameter determines the pipe bending die radius. The larger the external diameter of the round pipe, the larger the bending radius.

● Determine the size of the external diameter of the round pipe according to the required bending radius

When choosing round pipe external diameter, you should consider the required bending radius. In general, the bending radius should be 2 to 3 times the external diameter of the round pipe.

● For special processing needs, can choose nonstandard round pipe sizes

If you have special processing needs, you can choose nonstandard round pipe sizes. However, you should pay attention that the selection of nonstandard round pipe size will bring some difficulties to the determination of bending die size, die making and processing.

+86 19112905173

+86 19112905173