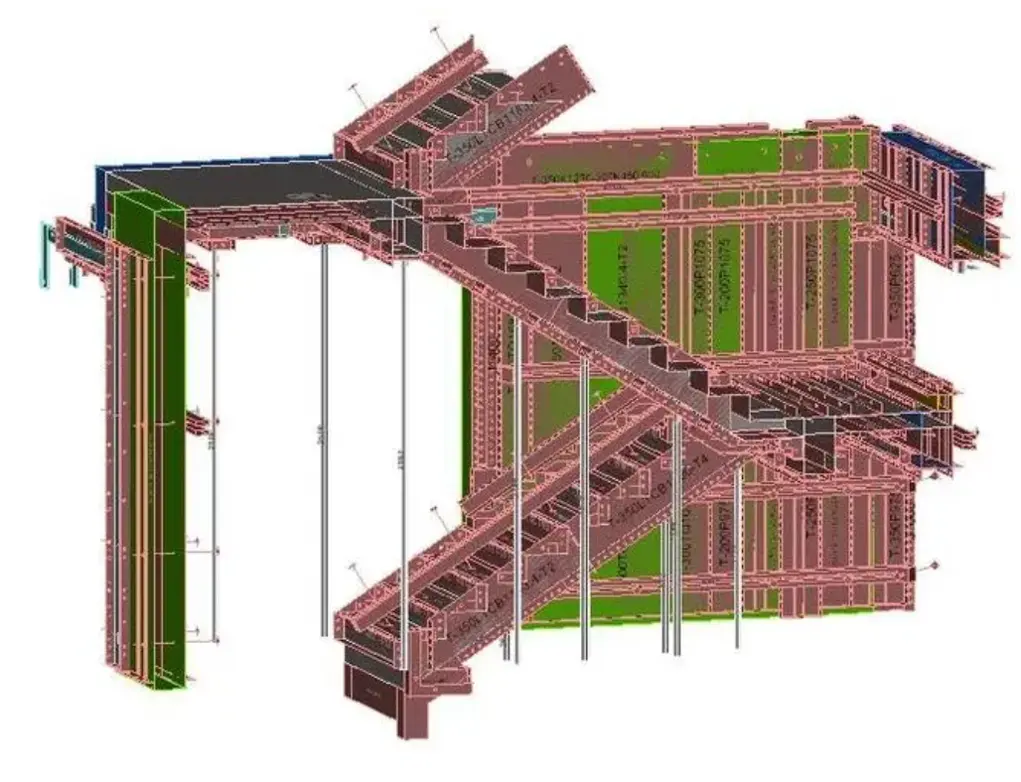

Staircase formwork construction

Staircases are vertical components in buildings that provide access for people and objects to move between floors. They are indispensable and essential elements of a building, particularly in multi-story and high-rise structures, serving a crucial role in vertical transportation.

For the construction of cast-in-place concrete stairs, staircase formwork is used to provide temporary support and shaping of the structure. Staircase formwork can be designed based on the actual shape and size of the stairs, offering support and positioning to maintain the accurate shape and dimensions of the stairs after the concrete pouring. The staircase formwork details parts include the steps, treads, and kickboards of the stairs. Staircase formwork plays a crucial role in construction, ensuring the stability and safety of the staircase structure. Through this article, we are providing users with a quick and safe construction solution for staircase formwork. If you need staircase formwork or want to learn more about construction details about staircase formwork, you can contact us via WhatsApp.

● staircase formwork procedure

The staircase formwork procedure involves several steps, such as staircase formwork calculation and design, staircase formwork measurement, staircase formwork installation, staircase formwork removal, and concrete curing. Only by completing these steps correctly can we build a stable and durable staircase.

1. Staircase formwork calculation and design are crucial steps to ensure stability and compliance with the safety requirements of the staircase structure. This involves calculating the dimensions, slope, number of steps, and heights of the staircase while determining an appropriate staircase formwork solution based on relevant regulations and standards.

2. Staircase formwork measurement. Before construction, it is necessary to accurately measure the position, length, width, and height of the staircase. This will provide precise references for the fabrication and installation of staircase formwork.

3. Installation phase of staircase formwork. Prior to installation, proper technical guidance is required for staircase formwork, ensuring its correct Installation.

4. Once the staircase formwork installation is complete, you can pour the concrete. Before starting the pouring process, make sure that the staircase formwork has been correctly installed according to the design requirements. During the pouring process, it is essential to pay attention to controlling the speed and uniformity of the concrete pour, to ensure that the concrete is filled solidly without any voids.

5. After the completion of concrete pouring, you can proceed with removing the staircase formwork. It is important to handle the staircase formwork removal with caution to avoid damaging the newly poured concrete. Once the staircase formwork removal is done, it is necessary to carry out concrete curing for the stairs to ensure their stability and durability.

6. Concrete curing involves maintaining appropriate humidity and temperature conditions to promote the strength development and maturity of concrete, thereby increasing the quality and lifespan of the stairs. This may involve measures such as covering the concrete, keeping it moist, and controlling the temperature to ensure the best curing effects during the necessary period.

● staircase formwork calculation and design

1. design :

(1). Based on the type of building and the position of the stairs in the floor plan, determine the form of the staircase formwork to determine whether it is a curved staircase formwork or a straight staircase formwork.

(2). Based on the characteristics and purpose of the stairs, determine the suitable slope for selecting the riser height (h) and tread width (b).

(3). Determine the staircase width (a) based on the number of people passing through and the size of the staircase.

(4). Determine the number of steps in the staircase. Divide the building height (H) by the stepping height (h) to obtain the number of steps N = H/h. The number of steps should be a whole number. Considering the form of the staircase, determine the number of steps in each staircase segment.

(5). Determine the staircase landing width (D).

(6). Determine the horizontal projection length of each staircase segment based on the initial tread width b.

(7). Calculate the staircase clearance to meet the required height clearance.

(8). Finally, draw a staircase formwork sketch and a cross-sectional diagram.

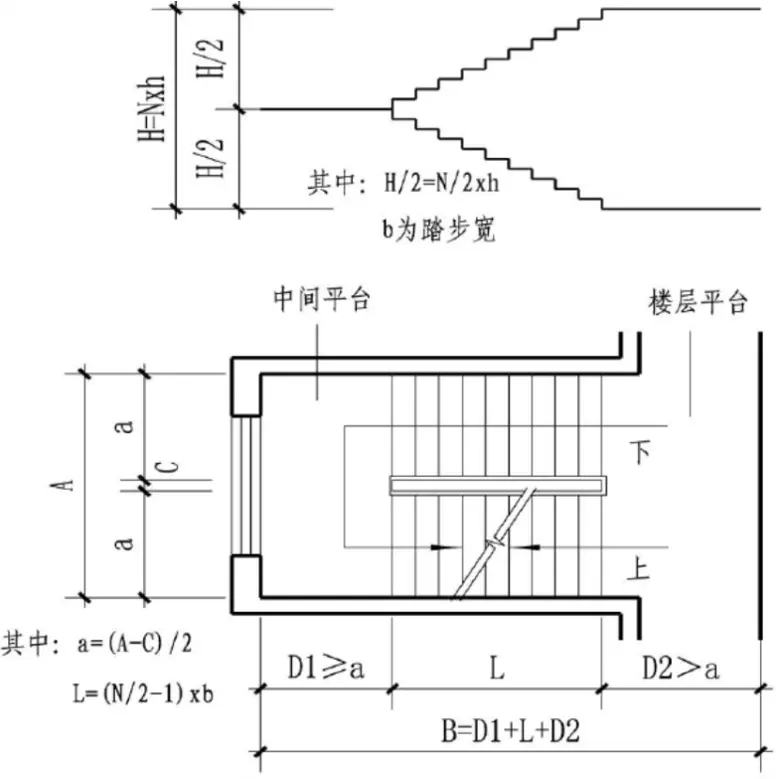

2.staircase formwork calculation

(1). Based on the floor height (H) and the chosen stepping height (h), determine the number of steps N for each floor: N = H/h.

(2). Based on the number of steps (N) and the tread width (b), determine the horizontal projection length of the staircase segment L: L = (1/2N-1) x b.

(3). Determine the stairwell width (C).

(4). Based on the net width of the stairwell opening A and the width of the stairwell C, determine the width of the staircase segment a: a = (A-C) / 2.

(5). Verify whether it meets the requirements for emergency evacuation of people (C). Calculate the net length of the stairwell depth (B) based on the width of the intermediate platform D1 (D1 ≥ a), the width of the floor platform D2 (D2 > a), and the horizontal projection length of the staircase segment L: D1 + L + D2 = B.

Note: The value of B is fixed, if the size is more than enough, the value of b and D2 can be widened generally.

● spiral staircase formwork installation

The construction sequence for spiral staircase formwork is as follows: Install the steps of spiral staircase formwork→install and reinforce the bottom beams of spiral staircase formwork. → Install the wall formworks at the stairs→secure the steel bars for the stairs→install the side formwork for the spiral staircase formwork→ Install and fasten the step for the spiral staircase formwork.

● The installation technology of spiral staircase formwork

1. Before assembling the spiral staircase formwork, check the structural elevation, layout dimensions, and positioning of steel bars.

2. The spiral staircase formwork consists of a step baseboard, step cover board, step sideboard, and steel waler.

3. The spiral staircase formwork is assembled using a fully enclosed method, and the step cover board needs to have a vibrating hole.

4. Pins and wedges are used to connect the step boards, sideboards, and wall boards together.

5. After the installation of spiral staircase formwork, it is necessary to use shoring props to prevent the formwork from expanding.

6. After the step installation is completed, it is necessary to reinforce the steps with steel waler.

● staircase formwork pouring

(1)When pouring concrete for staircase formwork, care should be taken to prevent concrete layering. Concrete should be poured after unloading through a hopper, with a maximum free fall height of around 2 meters. When pouring concrete for vertical structures, the height should not exceed 3 meters.

(2) When pouring concrete, it should be done in sections and layers continuously. The height of each pouring layer should be determined based on the structural characteristics and reinforcement density. Typically, it should be about 1.25 times the length of the vibrating part of the compactor.

(3)When using a plug-in vibrator, it should be inserted quickly and pulled out slowly. The insertion points should be evenly spaced and moved point by point in a sequential order without any omissions.

(4)When pouring concrete, it is important to regularly observe the staircase formwork, reinforcement, embedded holes, and fixtures for any signs of movement, deformation, or blockage. If any issues are detected, the pouring should be immediately stopped.

(5) The pouring of concrete for the staircase formwork should be done continuously, If there is a need for interruptions, the duration of these interruptions should be minimized as much as possible. The maximum allowable interruption time depends on the type of cement used and the concrete curing conditions. Generally, if the interruption exceeds 2 hours, it should be treated as a construction joint.

●Handling of construction joints for concrete staircase formwork

When continuing to pour concrete at the construction joints of concrete staircase formwork, the following regulations should be followed:

(1) The compressive strength of the already poured concrete should not be less than 1.2MPa.

(2) On the hardened surface of the concrete, remove any cement scum and loose stones. Thoroughly wet the surface with water, ensuring a wetting time of at least 24 hours, but without allowing pooling of water.

( 3) Before pouring the concrete, apply a layer of cement slurry at the joint, with a thickness of 10 to 15mm.

( 4) When continuing to pour from the construction joints, it should be poured gradually to the construction joints, and the tamping work on the joints of the construction joints should be strengthened to make them tightly bonded.

(5) After the completion of pouring concrete for concrete staircase formwork, it is important to avoid stepping on it and take proper protective measures.

● staircase formwork removal

1. The staircase formwork can only be removed when the concrete strength reaches 100% of the design strength. The removed formwork for staircase should be cleaned promptly, gathered together, and neatly stored.

2. The sequence and method of staircase formwork removal should follow the specifications provided in the formwork design. In the absence of specific design instructions, non-load-bearing parts should be removed first, followed by the removal of load-bearing parts (such as the bottom of the staircase formwork). Generally, the shoring props can be removed after a period of 21 days.

3. When the staircase formwork removal, it is important to avoid using force or throwing it away and try to prevent any damage to the concrete surface. After removal, it should be promptly cleaned up and transported away.

4. During the process of staircase formwork removal, if any quality issues are detected in the concrete that could affect the structural safety, the removal should be temporarily halted.

After the staircase formwork removal, it is important to properly cure the concrete to ensure the stability and durability of the staircase. This ensures the quality of the concrete and prevents the occurrence of cracks, and other structural issues.

For the curing of cast-in-place concrete stairs, natural curing is commonly employed. Natural curing refers to utilizing the natural conditions where the average temperature is above 5℃. It involves covering the concrete with burlap sacks, straw mats, sawdust, or sand, and periodically moistening it to keep the concrete in a damp state during a certain period of time for proper hardening. For regular plastic concrete, curing should begin within 6 to 12 hours after pouring if the highest temperature is below 25℃. If the highest temperature exceeds 25℃, watering and maintenance should start within 2 to 3 hours.

The frequency of watering should keep the concrete in a moist state. Typically, when the temperature is around 15℃, watering should be done 2 to 4 times a day. In hot and dry weather, it may be necessary to increase the frequency accordingly. When the average temperature during the day and night is below 5℃ or the lowest temperature drops below -3℃, special winter construction measures should be taken. It is important to avoid watering the concrete surface to prevent freezing of the structural components caused by sudden temperature drops.

If you want to know more about formwork construction, such as Precautions for dismantling aluminum shuttering system, don't hesitate to contact us.

● Recommended

+86 19112905173

+86 19112905173