staircase formwork

● what is stair formwork

Staircase formwork is a commonly used construction formwork employed for the placement and reinforcement of staircases. It is an auxiliary tool utilized for pouring concrete stairs and is typically made from materials such as wood, steel, or aluminium alloys. The primary function of staircase formwork is to provide a temporary supporting structure that allows the concrete to flow evenly and take on the shape of the staircase. It ensures precise geometric shape of the stairs and provides sufficient support to withstand the weight and pressure during the concrete pouring process.

Staircase formwork typically consists of multiple components, such as a step, waist slab, riser, landing, etc. These components are assembled according to design requirements to form a complete stair formwork system. During usage, the formwork needs to be securely fixed in place and adjusted or calibrated to ensure that the dimensions and flatness of the stairs meet the design specifications.

Staircase formwork effectively enhances the load-bearing capacity and stability of the staircase, ensuring its safety and reliability. During construction, workers need to operate according to design requirements, ensuring accurate and stable installation of the formwork and proper placement of reinforcement bars in accordance with relevant standards. Simultaneously, safety measures must be strictly followed to ensure the personal safety of the construction personnel.

● Aluminium formwork for staircase

Aluminium formwork for staircase is a formwork system made of aluminium material specifically designed for constructing staircase structures. It consists of various specifications and sizes of aluminium alloy components that can be adjusted and assembled according to the design requirements of the staircase. Aluminium formwork for staircase is widely adopted due to its lightweight, durable, easy installation, and reusable characteristics.

The aluminium formwork for staircase plays a significant role in enhancing construction efficiency and ensuring project quality.

1. Improving construction efficiency: Aluminium formwork for staircase features rapid assembly and disassembly, eliminating the complex processing and installation steps required by traditional wooden formwork. This can significantly reduce construction time. Furthermore, the precise geometric design and adjustability of the formwork ensure that the shape and dimensions of the staircase meet design requirements, avoiding the need for later repairs and adjustments.

2. Ensuring project quality: The high strength and stability of aluminium formwork for staircase guarantee the stability and load-bearing capacity of the staircase structure, preventing engineering quality issues caused by formwork instability. Additionally, the precise design of the formwork system effectively prevents problems such as unevenness and asymmetry in the staircase, improving the aesthetics and quality of the project.

3. Enhancing safety: Aluminium formwork for staircase is constructed using high-quality aluminium alloy material, which possesses excellent compressive strength and wear resistance. It provides a reliable support structure, reducing the risk of formwork collapse. Additionally, the formwork surface is typically designed to be slip-resistant, providing a safe working environment for workers and reducing the risk of accidents.

So, aluminium formwork for staircase plays a crucial role in improving construction efficiency and ensuring project quality. It not only accelerates the construction progress and saves time and labor costs but also guarantees the stability and aesthetics of the staircase structure, enhancing project quality. Moreover, it provides a secure and reliable working environment for workers. Therefore, it is widely applied in modern construction projects and has become an efficient tool for both high-efficiency construction and high-quality engineering.

● Aluminium formwork of staircase:

High strength: The aluminium formwork of staircase is constructed using high-strength aluminium alloy material, which exhibits excellent compressive and bending resistance. It can withstand significant loads while maintaining the stability and durability of the staircase structure. Experimental test data have demonstrated that the aluminium alloy possesses a bending strength three times that of ordinary steel materials, with a tensile strength of ≥180 MPa and a yield strength of 180 MPa.

2. Lightweight and easy to transport: The aluminium formwork of staircase is lighter , weighing approximately 25kg/m². This makes it easier for workers to transport and manipulate the formwork on the construction site. It reduces the need for heavy lifting equipment and improves operational efficiency.

3. High reusability: The aluminium formwork of staircase exhibits high reusability, as it is resistant to wear and deformation. It can be reused for approximately 300 cycles. In contrast to disposable wooden or steel formwork, aluminium staircase formwork significantly reduces material waste, lowers costs, and is more environmentally friendly.

4. Quick assembly and disassembly: The aluminium formwork of staircase adopts a simple assembly method, where the components are connected using connectors. This design enables a fast and efficient installation and disassembly process, with form removal typically taking 18-36 hours, thus saving time and costs. Additionally, the easy disassembly feature facilitates cleaning and maintenance of the formwork.

5. Precise design and adjustment capabilities: The aluminium formwork of staircase allows for precise adjustment and assembly according to the specific design requirements of the staircase, ensuring geometric shape accuracy and consistency. It possesses high dimensional precision and flexibility, with geometric dimensions maintained within a tolerance of 3-5mm for verticality and flatness. This helps to avoid issues such as uneven or asymmetrical staircases, thereby enhancing the quality and aesthetics of the staircase.

6. Easy operation: The staircase formwork procedure is simple and does not rely on formwork technicians with long-term experience. It is easy to learn the assembly and disassembly process. Skilled installers can install 30 square meters per day, while regular workers can independently operate after simple training.

If you would like to learn more about the aluminium formwork of staircase or buy concrete stair formwork, you can contact us via WhatsApp.

● Aluminium concrete stair formwork design

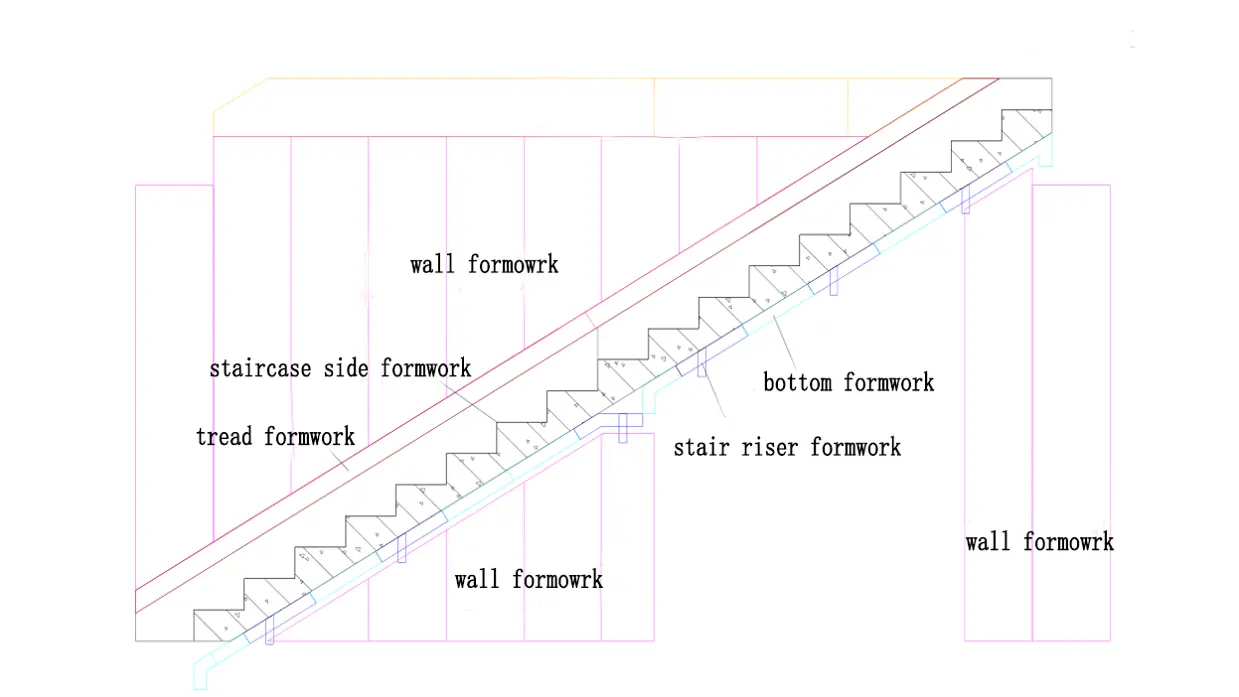

The aluminium concrete stair formwork systems consist of components such as the tread formwork, bottom formwork, bottom stringer, wall formwork, staircase side formwork, and side closure panels. Among them, the standard size for the aluminium stairmaster formwork is 400x900mm, with adjustments made to accommodate the actual structural dimensions.

The aluminium concrete stair formwork systems support system is illustrated in the diagram, with the red circles indicating the stairmaster formwork support heads and the rectangular bars representing the support stringers. In this particular case, the support system is equipped with 4 sets of support stringers. When the concrete reaches the demolding time, only the staircase formwork is removed while the staircase support system is retained, allowing for quick demolding. The spacing between the support heads at the lower part of the staircase is 1000mm each, evenly distributed on both sides of the staircase base.

● install of stair formwork systems

The construction sequence for stair formwork systems is as follows: Installation of stairmaster stair formwork → Installation and reinforcement of staircase bottom stringers → Installation of wall formwork at the staircase location → Reinforcement of staircase rebars → Installation of staircase side formwork → Installation of staircase tread formwork → Securing of staircase tread formwork. As the staircase area serves as the only access point for operations throughout the entire tower, it is essential to promptly install and reinforce the bottom stringers when constructing formwork for stair.

● Formwork for stair Installation technology

1. The stair formwork design adopts a fully enclosed assembly process, where it is assembled together with the adjacent wall formwork (using special C-slot connections). Vibration openings need to be provided on the tread formwork.

2. Parts of stair formwork, such as the tread formwork, side panels, and shear wall formwork, are all connected using dowel pins..

3. After the installation of the treads is complete, the tread formwork is further reinforced.

● Staircase formwork removal

Formwork removal time for staircase is set at 5-7 days, with the condition that the concrete attains a strength of 75%.

1. Spans of 2 meters or below should achieve 50% of the design strength.

2. Spans between 2 and 8 meters should achieve 75% of the design strength.

3. Spans exceeding 8 meters should achieve 100% of the design strength. It is strictly prohibited to excessively pile building materials on removed floor slabs until they have reached 100% strength.

● Categorization of stair formwork

The choice of formwork for staircase construction depends on the specific type of staircase. We will now present four commonly used types of stair formwork along with their respective applications.

★curved staircase formwork

Curved staircase formwork is designed specifically for the construction of curved staircases, including spiral staircase formwork. Curved staircases generally follow a circular or elliptical path. These staircases are characterized by their graceful and visually appealing appearance, making them well-suited for public buildings where space-saving is crucial. However, the formwork required for curved staircases is intricate, posing challenges during construction. The structural forces involved are complex, resulting in a greater demand for concrete and steel. Moreover, the structure itself carries a significant self-weight. 。

curved staircase formwork

★ Straight stair formwork

Straightstair formwork is designed specifically for constructing straight staircases, which are the most basic type of staircase. The overall shape resembles a straight line. In situations where the staircase is considerably long, a resting platform can be incorporated in the middle to prevent direct falls to the lowest level. The design of the staircase should avoid excessively steep inclines.

★ Platform stair formwork

Platform stair formwork is used for constructing platform staircases. A staircase platform refers to the horizontal section that connects two flights of stairs. The platform serves as a transition point in the staircase, providing a connection between different levels or allowing users to take a rest after climbing a certain distance.

★Floating stair formwork

Floating stair formwork is used for constructing floating staircases, also known as cantilevered staircases. From the exterior view, all steps appear to be suspended in mid-air, with only the side of each step connected to the wall. The floating effect is achieved by concealing the fixed devices and supporting structures within the wall.

● knowledge

★How do you calculate staircase formwork?

By utilizing staircase formwork calculation, which includes determining parameters such as slope ratio, slope coefficient, and hypotenuse length, it is possible to accurately calculate the area of the formwork and the required amount of concrete, as well as budgeting. This process can assist in optimizing the construction plan for staircases.

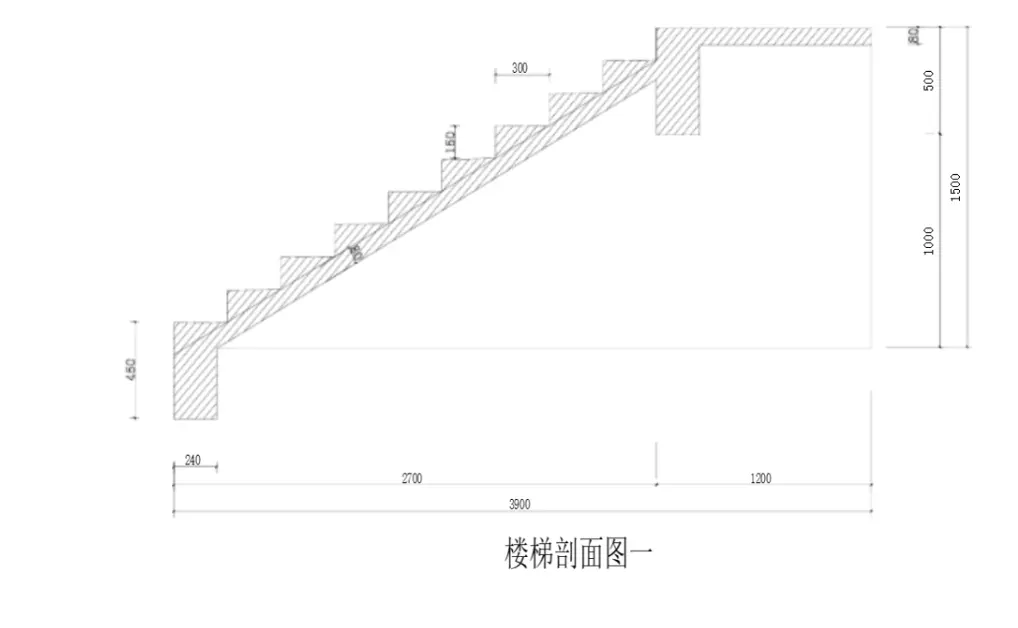

1. The height and width of each stair tread form a right-angled triangle, which is similar to the right-angled triangle formed by the staircase base and its horizontal projection. The slope ratio and slope coefficient of each tread are equivalent to the slope ratio and slope coefficient of the staircase base and its horizontal projection. Refer to Figure (Staircase Profile 1) for illustration.

(1) Tread height = 150mm, tread width = 300mm

(2) Applying the Pythagorean theorem, the length of the hypotenuse of each tread is calculated as: 335.41mm

(3) Slope ratio = short side/long side = 150/300 = 0.5

(4) Slope coefficient = hypotenuse/long side = 335/300 = 1.118

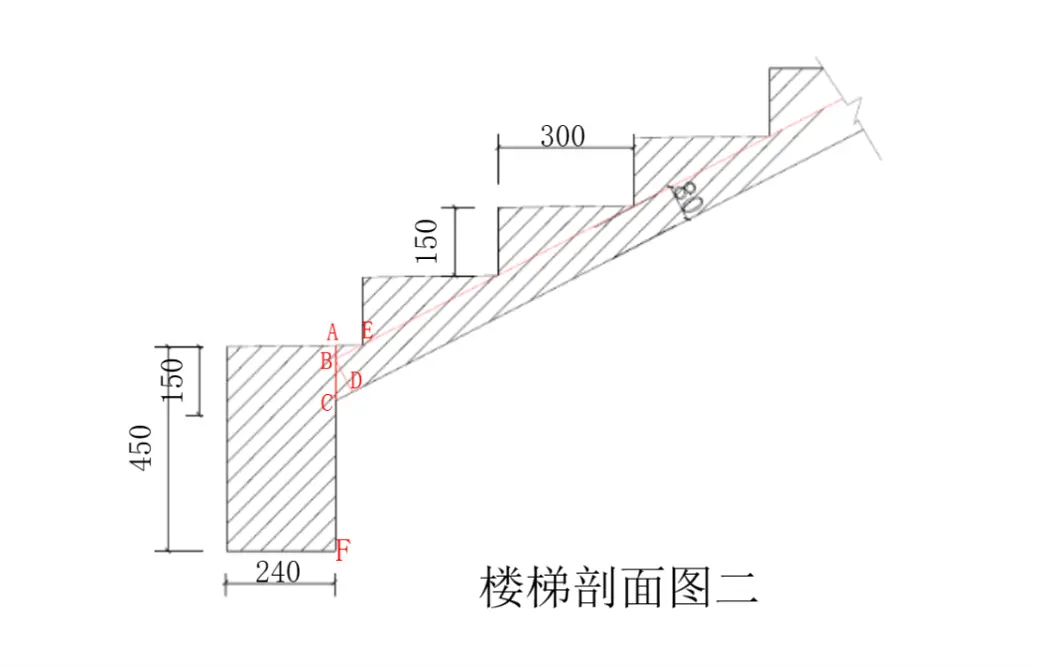

2. The height of the outer formwork is 450mm, and the height of the inner formwork (CF)= height of the outer formwork-AC (refer to Staircase Profile 2).

AC = AB + BC

AE = 300 - 240 = 60mm

AB = 60 × 0.5 = 30mm

BC = 80 × 1.118 = 90mm

AC = 30 + 90 = 120mm

Inner formwork height (CF) = 450 - 120 = 330mm

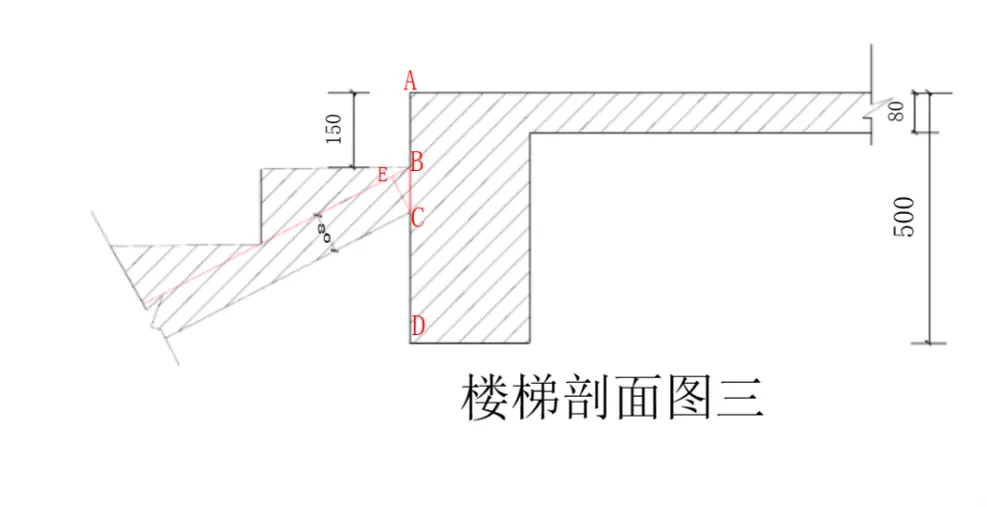

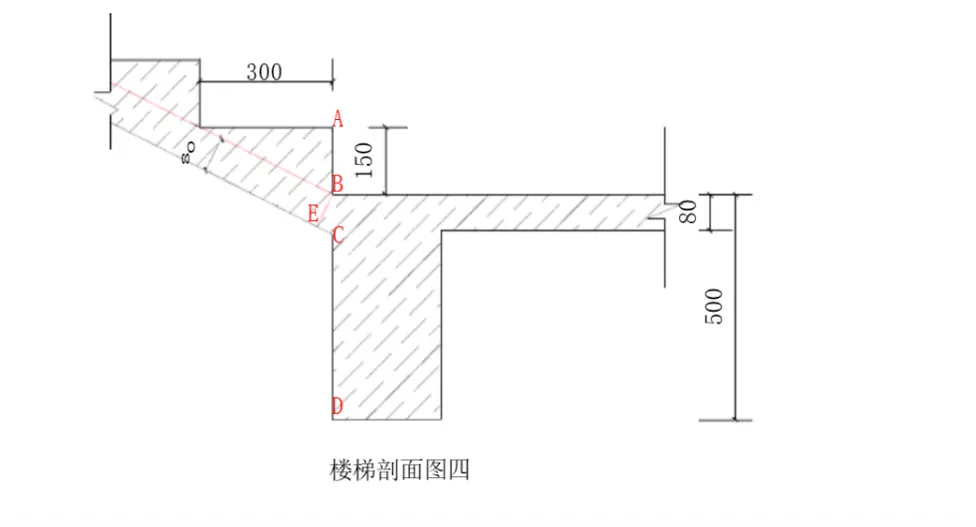

3. inner side formwork calculations for the first segment of the staircase

CD = AD - AC

AD = 500mm

AC = AB + BC

AB = 150mm

BC = 80 × 1.118 = 90mm

CD = 500 - 150 - 90 = 260mm

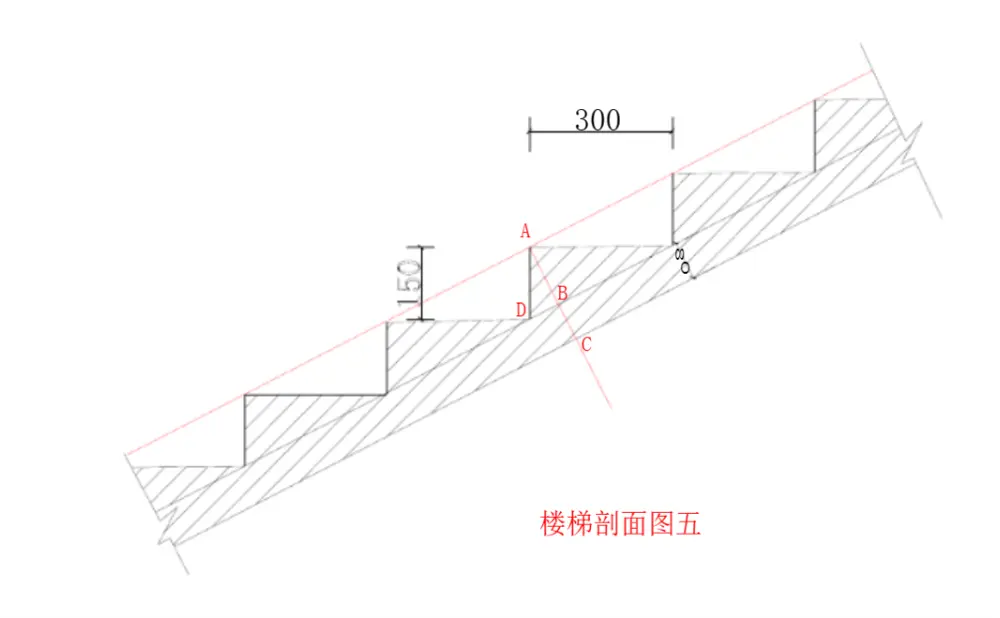

4. inner side formwork calculations for the second segment of the staircase

CD=BD-BC

BD=500mm

BC=80×1.118=90mm

CD=500-90=410mm

5. The length of the bottom formwork= horizontal projection length of the bottom formwork * slope coefficient.

horizontal projection length of the bottom formwork=2700-240-30(formwork thickness)-30(formwork thickness)=2400mm

the length of the bottom formwork=2400×1.118=2683mm

6. Calculation of Side Formwork for Staircase:

AC = AB + BC

BC = 80mm

AB = 150÷1.118 = 134mm

AC = 134 + 80 = 214mm

For example, if there are 17 steps in each level of the staircase, with each step measuring 24cm in length and 12cm in height, the length of the hypotenuse would be 26.83cm. With 17 steps, there would be 17 hypotenuse, resulting in a bottom formwork length of 456cm, considering a staircase width of 120cm.

The area of the bottom formwork is calculated as 4.56 * 1.2 = 5.47 square meters. Additionally, the area of the internal formwork is 1.2 * 0.12 * 17 = 2.45 square meters. The side formwork area is 4.56 * 0.11 = 0.5 square meters. Therefore, the total formwork area for,staircase formwork is 5.47 + 2.45 + 0.5 = 8.42 square meters.

★ Do you need rebar in concrete stairs?

Rebar is required in formwork on stair to enhance its load-bearing capacity and stability. The rebar can be embedded in the stair structure before pouring the concrete, ensuring integration between the rebar and the concrete to improve the strength and durability of the stairs. Furthermore, the incorporation of rebar helps prevent issues such as cracking or deformation in the stairs over time.

Before pouring concrete into shear walls, reinforcement should be pre-installed at corresponding locations based on elevation and drawings. The reinforcement should extend 25cm into the concrete, with the exposed length of short bars being 20 times the diameter of the rebar (20d), and long bars being 35 times the diameter of the rebar (35d). The ratio of joints between long and short bars should be determined based on 50% of the length of the long bars. For the steel reinforcement reserved in the stair platform slab, it should protrude 50cm externally, with the reinforcement extending 25cm into the concrete. The steel reinforcement in the reserved reinforcement includes welding on one side for beam bars, while for the stair platform slab, the construction should follow overlapping methods.

● Recommended

+86 19112905173

+86 19112905173