Stamping Die

Stamping die is the die fixed on stamping machine. It put certain amount of pressure on sheets to form the materials, in order to get parts with certain size requirement and qualified appearance and quality.

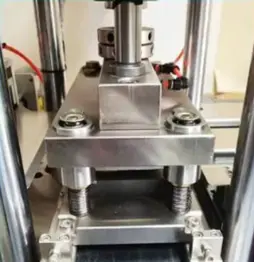

Stamping die usually concludes upper and lower die, die set, guide pin, discharging rack, etc. The precision and quality of these parts determines the service life of stamping die and the quality of stamping products. Stamping die can perform repeated stamping, bending and drawing to make the metal sheets into required parts.

● principle of stamping die process

The principle of stamping die process: at room temperature, use the die fixed on stamping machine to put pressure on materials to make separation or plastic deformation, in order to get the required parts. This process not only include simple blanking, dropping and punching, but also include more complex forming process like drawing, bending and expanding.

Stamping die design and stamping dies manufacturing are the core of stamping process. First, we design the dies corresponding to products requirement. The metal stamping die design needs to consider the shapes, sizes and materials of products. Then, we use highly precise machine and tool to begin stamping dies manufacturing to ensure the precision and quality of the die.

Stamping die process involves multiple aspects, including pressing, feeding, positioning, pressing, and discharging. In forming process, stamping die will move up and down. The upper die put pressure on the lower die, forming the metal materials according to the shape of die. In the process, metal materials are controlled and deformed by external force and the metal particles produce displacement and densification changes, which ultimately results in molding.

● die stamping benefits

1, Achieve high precision. Due to the improvement of metal stamping die factories technology, stamping dies manufacturing use computer numerical control, the precision of stamping press die block is relatively high, reducing the mistakes in processing.

2, Achieve mass production. Due to stamping die manufacturing process is easy and processing efficiency is high, making parts with the same specifications rapidly and mass production can be realized. In the manufacturing industry, especially in the car and electronics industries, the stamping process reaches a level of automation, which can greatly improve efficiency and reduce costs.

3, Reduce processing periods. stamping die manufacturing is relatively simple and the processing periods are short, which can meet the urgent needs of production.

4, Enrich products types. Due to stamping press die can make parts with various shapes and sizes, processing diversification can enrich products types to improve quality and market power.

● metal stamping die for sale parameter

| name | metal stamping die |

| die set | It is made by chromium 12 heat treatment and wire cutting, and not easy to break and have high stability. |

| stamping knife stamping die materials | Molybdenum-vanadium steel has good toughness and high hardness. Wear-prone specifications can use tungsten steel or DC53 material. |

| materials processing | The hardness reaches above HRC58℃ after heat treatment, so it has strong toughness. |

| stamping die manufacturing process | The shape of the die is formed by wire cutting into an arc, no burrs, and the arc is flat. |

| die specification | It is customizable.one specification, one stamping die clamps |

| die thickness | It can be customized according to customer's requirements, the difference of 50 thickness share the same set of dies. |

● stamping die components

In the metal stamping processing industry, a set of complete stamping die is indispensable. Stamping die usually consists of many key parts, including the head of stamping die punches. They are key parts used to form specific shapes in materials. In addition, the stamping die also includes various parts, such as stamping die parts, stamping die attach, stamping die bushings and stamping die bracket. These parts ensure the stability and accuracy of the die.

The stamping die box of stamping die is a shell to contain and protect all inner parts. The stamping die cam of stamping die is to drive the die to move. These complex parts need accurate design and manufacturing, ensuring the desired result in stamping process.

In order to meet the needs of different industries for high quality stamping die, professional stamping die manufacturers can provide specific solution and ensure that our customers can buy stamping meeting their specific needs through continuous technological innovation and process improvement.

● stamping die applications

Stamping die cost is low and efficiency is high. Stamping die is wide used in mechanical, car, electronics, household appliances, architecture, aerospace fields, etc.

1, mechanical field: In traditional machine manufacturing, stamping die is usually used to make various parts like gear and bearing.

2, car field: stamping die automotive is very important in car manufacturing and it almost covers the entire aspects of car manufacturing, such as car frame, car door, hood and other metal parts. Car manufacturers will use stamping dies as one of their core competencies, effectively improving production efficiency and quality.

3, electronics field: With the rapid development of technology,stamping die process begin to applied widely in electronics field, usually used for making metal shells, meatal connectors, etc.

4, household appliances field: die stamping equipment is used to make various shells and parts of household appliances, such as TV shell, fridge door , washing machine cylinder, etc.

● common machine types of stamping dies

1, punch press machine

Punch press machine is a common machine type in punching processing. It has the nature of high speed, high precision and high production efficiency. Punch press is widely used in car, electronics, household appliances industries.

When using stamping die on the punch press machine, please pay attention to suitable size and type of dies to ensure the processing precision and production efficiency.

2, numerically controlled machine tool

Numerically controlled machine tool is another type of machine usually used to process stamping dies. Compared with traditional manual machines, it has higher processing accuracy and production efficiency. For those companies using numerically controlled machines for stamping, please pay attention of the choice of machine type, control system, and the selection of tools and fixtures.

3, injection machine

Injection machine is also a one of the machines which can use punching die to stamp. The parts produced by injection machine can be cut by punching die and be formed into corresponding shapes. When using injection machine, please select suitable plastic materials, specifications of die and machine types, ensuring processing quality and efficiency.

4, shearing machine

Shearing is a stamping die machine specially used for sheet metal processing, commonly used in cars, machinery and other industries. The use of shears for stamping die processing requires attention to the selection of the suitable thickness, size and angle of the shearing machine to ensure processing quality and efficiency.

+86 19112905173

+86 19112905173