Aluminium shuttering

Aluminium shuttering price:170USD/M2

● What is aluminium shuttering

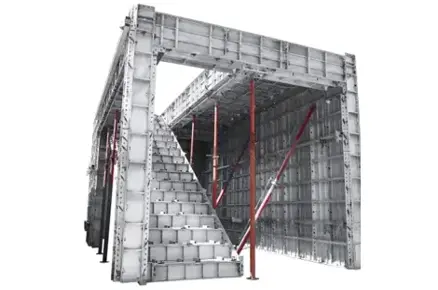

Aluminium shuttering is a temporary support structure made of aluminium alloy. They are used to create the shape and dimensions of walls, floors, stairs, beams, or other structures, ensuring that they meet design requirements and standards. Because each component of the aluminium shuttering is machine processed in the factory, the flatness and quality of the joints are ensured. By employing innovative aluminium shuttering technology, the load-bearing capacity of residential buildings can be improved. Adopting structural insulation integration can eliminate issues such as hollowing, effectively reducing cracking and enhancing overall housing quality. So, more and more construction units adopt aluminium shuttering system which can effectively ensure the accuracy and stability of concrete and components while improving construction efficiency and reducing construction costs.

● Aluminium shuttering parameters

| Material type | Complete extrusion |

| Thickness of panel | 4mm |

| Thickness of frame | 8mm |

| Height of frame | 65mm |

| Average weight | 22-25KG/Sqm |

| Raw materials | Aluminium alloy 6061-T6 |

| Standard wall panel width | 50mm to 600mm |

| Standard slab panel size | 400x1100mm |

| Surface treatment | Mill finish or Powder coating as client's requirement |

● Aluminium shuttering advantages

1. The aluminium shuttering system is characterized by its lightweight nature, with a weight of typically around 22-25kg per square meter. As a result, it enables fast construction speed and short project duration, meeting the requirements for construction efficiency.

2. The material of aluminium shuttering plates is aluminium alloy, which has a high level of reusability and a relatively low average usage cost, allowing for significant savings in production costs.It can be reused 300 times.

3. Aluminium shuttering material present excellent stability with high load-bearing capacity.It can withstand a load of 70kW/m2.

4. Aluminium shuttering plates can be assembled into formwork of different sizes and shapes, solving some of the shortcomings of traditional formwork and improving work efficiency. In theory, using aluminium shuttering plates can achieve the effect of no plastering, but it is necessary to ensure proper vibration and correct construction procedures during the construction process in order to maximize the effectiveness of aluminium shuttering.

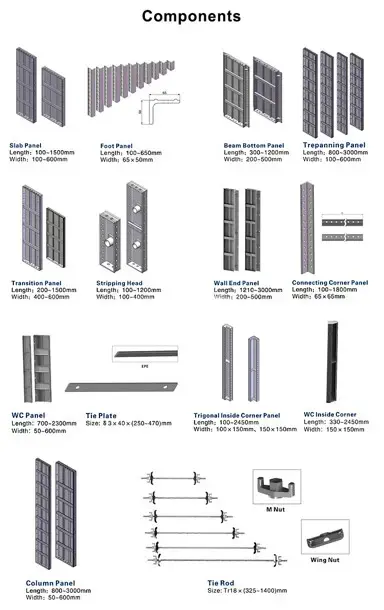

● Aluminium shuttering components

Aluminium shuttering system provide a one-time molding, overall pouring, and precise construction with minimal errors and high accuracy to ensure the overall strength and service life of buildings. They are particularly suitable for high-rise buildings as well as single-story villas. Many components are required for the construction of aluminium shuttering pans, which play a vital role in the construction process.

● Aluminium shuttering components tools

Hole Bari Tool are used to align holes with each other and reinforce the locking pins and wedges.

Panel Puller are used for the quick removal of the aluminium shuttering plates.

Transfer Box is used to transfer aluminium shuttering pans between two floors.

● Aluminium shuttering sheet application

The aluminium shuttering sheet serves as an efficient and reliable construction support system, widely applied in various projects such as high-rise buildings, apartment complexes, commercial structures, bridges, and villas. As a result, its utilization can be observed in an increasing number of countries and regions worldwide, including Hong Kong, Macau, Indonesia, the Middle East, and others. As a professional aluminium shuttering manufacturers, we provide the price of aluminium shuttering wholesale

● FAQ

▲ The installation and dismantling process for aluminium shuttering plates

Measuring and setting out→installing wall columns steel bars and water and electricity →apply shuttering oil for aluminium formwork→installing wall columns aluminium shuttering→installing shuttering aluminium beam →installing decks aluminium shuttering→installing deck steel bars and water and electricity→adjusting and reinforcing the aluminium shuttering system→checking and accepting→pouring concrete→curing the concrete→dismantle wall columns aluminium shuttering→dismantle shuttering aluminium beam→dismantle decks aluminium shuttering plates→clean→transport→cycle construction

The installation of aluminium shuttering technology is similar to building with blocks. Take a double-storey villa as an example, first, based on the site's dimensions and design drawings, the aluminium shuttering is prefabricated and assembled to confirm its accuracy. It is then transported to the construction site, and the workers start aluminium shuttering construction according to their assigned numbers. Finally, steel reinforcement is used to secure the structure, and concrete is poured into it. Once the concrete has dried, the construction work is completed.

▲Aluminium shuttering vs conventional formwork

1. Integrated construction

Aluminium shuttering system adopts an integrated construction method, which minimizes the possibility of leaks at window sills and exterior walls.

2. Reduced hollowing and crack.

This aluminium shuttering technology can maximize the reduction of wall surface cracking problems.

3. High-precision construction.

Due to the advanced aluminium shuttering technology in construction, there has been a significant improvement in construction precision.

4. High-quality aluminium material.

Aluminium extrusions have strong rigidity, and according to relevant data, can be reused at least 200 times, guaranteeing the construction process and promoting recycling value.

5. Energy-saving and environmentally friendly, leading the way in green buildings.

Aluminium shuttering material is a renewable material that greatly reduces the waste of traditional wood materials and is energy-saving, environmentally friendly and low-carbon.

▲Aluminium shuttering pans construction precautions

1. When aluminium shuttering construction, it does not allow carpenters to cut or polish the formwork. If there are issues with loose assembly or an inability to fit properly, it is necessary to check whether the bolts are tightened and whether there are any assembly errors.

2. It is recommended to arrange for workers to learn the aluminium shuttering technology of assembling and disassembling at the aluminium shuttering manufacturers before pre-assembly. This can improve construction efficiency and quality on site.

3. When installing aluminium shuttering components, aluminium shuttering oil must be evenly applied.

4. The aluminium shuttering pans system should undergo three measurements. The first measurement should be made after the wall column assembly is complete, to precisely control the elevation, flatness, and verticality of the aluminium shuttering pans. The second measurement should be made after the deck aluminium shuttering pans is installed, with real-time adjustment of the flat tie, steel waler, push-pull prop, shoring props, and waller clamp. If it is found that the error between the aluminium shuttering pans and the control line exceeds 4mm, it should be adjusted in time. The third measurement should be made within 30 minutes after pouring and adjusting as necessary.

5. During the dismantling process, it is important to take measures to protect the aluminium shuttering sheet and avoid rough handling. After removal, it is necessary to promptly clean the surface of the concrete.

● Recommended

+86 19112905173

+86 19112905173