steel formwork system

Since its inception in the United States in 1962, the steel formwork system has been widely used in the construction industry of emerging industrial countries, such as steel formwork malaysia, steel formwork in bangladesh, steel formwork nz, steel formwork philippines, steel formwork singapore, and steel formwork hk. Its application is also very common in Mexico‘s affordable housing projects. In Korea, the application of steel formwork system in high-rise residential construction has increased from 20% to 80% over the past decade. The steel formwork system adopts efficient installation methods and high-quality forming to reduce dependence on manual labor, promoting the standardized and universal development of the construction industry. The following introduces the application of our aluminum formwork in the Jin Yu Fu project.

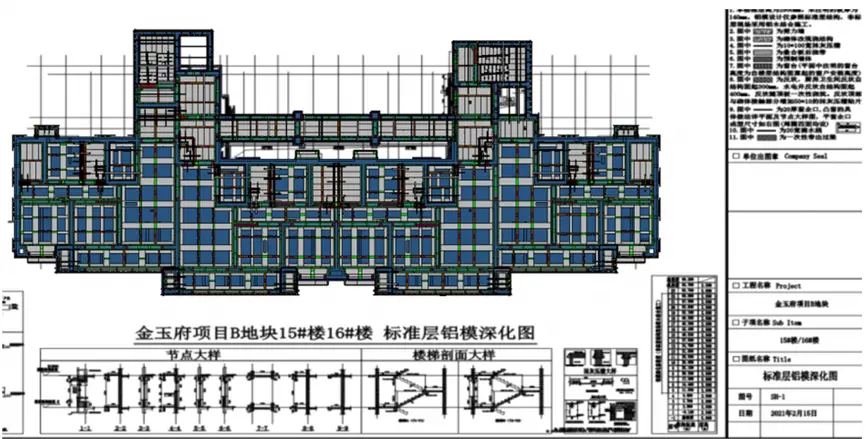

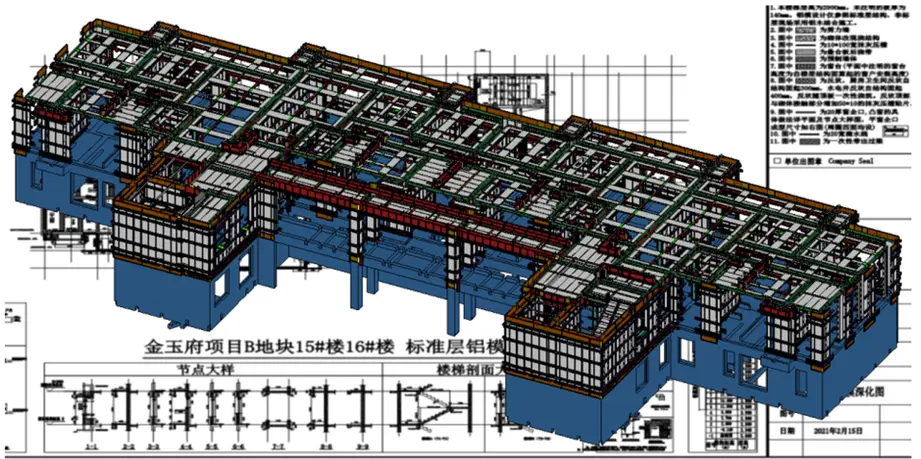

The 15# and 16# floors of the Jin Yu Fu project have the same standard floor structure and deepening requirements, so design only needs to follow the deepening design of one building. The height of this building is 2.9 meters, with a composite slab structure for the roof and a vertical prefabricated component thermal insulation integrated assembly structure for the external wall. The external scaffold adopts a I-shaped steel cantilever structure.

● What is steel formwork

The steel formwork system is an integrated solution that combines formwork, support systems, and construction techniques. The use of steel formwork increases the number of uses and reduces construction costs, thus significantly reducing the waste and consumption of forest resources in the construction industry.

Before construction, professionals use computer-aided design to standardize, modularize, and systematize all the required formwork for the project (including steel formwork for slab, steel wall formwork, steel ply formwork, steel props formwork, and steel waler formwork). The system can meet construction requirements, with steel formwork sizes reaching up to 2700mm x 400mm and a minimum steel formwork size of 50mm x 50mm. All formwork is designed in accordance with specifications, and the system's bearing capacity follows the standard of 60KN/m2. The structural design and accessories of the formwork have undergone rigorous mechanical calculation and strength testing to ensure that no formwork expansion occurs during concrete pouring, ensuring that the flatness and verticality of walls, columns, and floors are within the design range. The steel formwork pegs and steel formwork pins are used for connection, making installation and removal quick and easy. After dismantling formwork, the concrete surface is flat, achieving the effect of fair-faced concrete, eliminating the need for plastering, thus saving time, labor, and material costs.

Based on the steel formwork drawing, a list of required formwork and steel formwork accessories for the project is provided. After completion of production in the factory, each formwork and accessory will undergo strict quality management and coding. Before being transported to the construction site, all formwork and accessories will undergo 100% overall trial installation to address any potential errors and oversights. This method can effectively guarantee the quality and efficiency of on-site construction. With simple training for workers, they can easily perform simple assembly operations according to the drawings, completing on-site construction quickly, efficiently, and safely.

● Steel formwork advantages

1.steel formwork design: Through steel formwork design calculation, detailed and accurate analysis of the project is carried out, and construction plans are optimized to a maximum extent in order to resolve potential issues that may arise during construction at the design stage.

2.High-quality: The steel formwork system uses high-strength aluminum alloy profiles welded into various standardized components according to different requirements. The precision of the formwork is far higher than that of traditional formwork.

3.Trial installation: In traditional formwork and construction methods, many installation issues are typically handled on-site by construction workers randomly, which makes it difficult to ensure construction efficiency and project quality. However, in steel formwork system, before being transported to the construction site, 100% overall trial installation is carried out, pre-solving all potential problems that may arise, greatly improving actual construction speed and accuracy.

4.High construction efficiency:Steel formwork system mainly uses pins and wedges as the primary connection method, making steel formwork installation extremely simple. Workers only need basic training to operate and can complete the task with just a hammer. Due to its lightweight, workers can manually transport it layer by layer, without relying on cranes, which can greatly accelerate construction progress and improve efficiency.

5.Early stripping technology: The deck panels and support system of steel formwork system are designed integrally, incorporating early stripping technology into the roof support system, greatly improving the turnover rate of the formwork.

6.Safety construction: The design of steel formwork system, including the wall panel, deck panel, adjustable shoring props, and related accessories, has undergone complete calculation and experimental verification, ensuring that the entire system meets the design standard of 50KN/m2. According to relevant US standards, there is a safety factor of 2:1, which avoids the safety hazards caused by uncertainties in traditional support methods.

7.recyclable:Steel formwork system is made of recyclable aluminum alloy material, which can be fully recycled and reused. The construction site is clean and orderly, without generating any waste.

● Service Process

1. Project pre-evaluation

During the preparation stage of the project, our sales and technical team, a service team, directly communicates and exchanges with the customer. After receiving the building and structure drawings from the customer, based on the actual situation of the project, we provide users with technical feasibility analysis and commercial evaluation of the project, helping customers to determine the best construction plan in terms of both technology and cost.

2. Construction plan and product design

After signing a cooperation intention agreement with the customer and receiving the customer‘s advance payment, our professional designers will draw up the formwork layout drawing, formwork installation drawing, and detailed material list for the customer, and provide users with detailed technical documents such as steel formwork installation guide.

3.trial installation.

After the steel formwork system is designed and manufactured, a trial assembly will be conducted in the factory. Any potential problems will be corrected at the first time. Before packaging and shipping, each component of the formwork will be coded and a detailed packaging and shipping list will be registered, so that installation can be quickly checked on site during construction.

4.Technical Services

After the formwork is transported to the construction site, we will provide professional technical guidance to customers and assist with installation and construction. At the same time, we will maintain timely communication with customers to address any unexpected events that may occur on the construction site. If the construction site is not local, the customer shall bear the travel expenses of the relevant technical personnel.

5. Supply of spare parts

We will provide customers with continuous follow-up services, including timely supplementation of lost or damaged formwork and accessories on the construction site to avoid delays in construction that may affect the project schedule.

6. Formwork repurchase

There may be two situations where the formwork needs to be repurchased during the use of the steel formwork system. For different projects, approximately 10%-30% of the irregular formwork becomes unusable for the customer after the entire project is completed. The other situation is that the user wants to exchange old formwork with new ones after multiple uses. In either case, we will negotiate with the customer and provide a repurchase plan that is mutually agreeable.

7. Cooperation mode

Customers can choose to purchase, rent, or opt for EPC (Engineering, Procurement, and Construction) services. If the customer chooses the EPC service, we will provide a project team consisting of a project manager, product design engineer, installation engineer, and skilled workers to be responsible for construction to ensure safety and efficiency on-site.

● Problems in traditional formwork construction

The traditional construction method using wooden formwork and backing of wooden waler has a large number of uncontrollable factors that affect the construction quality and efficiency. It is difficult to effectively control construction quality, efficiency, and safety issues.

Currently, steel pipe clamps and cuplock scaffold are widely used in the support system of deck panels. However, these support systems are relatively independent of the formwork system, lacking integrated design, which leads to low construction efficiency and poor quality while wasting materials and working hours. Due to improper use of props equipment and construction schemes, safety accidents often occur, sometimes even resulting in serious casualties. In order to effectively solve these problems, steel plate formwork can be adopted.

With the increase of labor costs, the inefficient formwork system has become unsustainable. This method not only wastes forest resources such as wood but also violates the purpose of green environmental protection and causes a significant increase in construction costs. The key to solving these problems is to adopt a new steel plate formwork that is highly efficient, modular, and reusable. At the same time, as many problems as possible that occur on construction sites should be processed and completed in factories to improve construction efficiency and quality.

● Recommended

+86 19112905173

+86 19112905173