beam formwork

● definition of beam formwork

Beam formwork is a temporary structure used in construction and engineering projects to support and secure concrete beams. It is primarily utilized to maintain the geometric shape of the beams, providing both lateral and longitudinal support. This ensures that the concrete receives proper support and positioning during the pouring and curing processes, preventing deformation or settlement.

Beam formwork is typically made from materials such as wood, steel, or aluminium alloys, possessing appropriate stiffness and strength to withstand the weight of concrete pouring and other loads.

Beam formwork design and construction need to take into account factors such as beam dimensions, load conditions, and construction techniques. Proper design and correct construction practices can enhance construction efficiency and quality.

● What is beam formwork of aluminium

aluminium beam formwork typically consists of three components: beam bottom formwork, beam side formwork, and beam formwork support. Beam bottom formwork serves as the formwork that supports the concrete and is usually in a flat shape. Its purpose is to ensure that the concrete solidifies and takes shape. On the other hand, beam side formwork is responsible for forming the boundaries of the beam, creating a closed space within the bottom formwork for the concrete to flow from the bottom and fill the entire space adequately. The overall shape and dimensions of the beam are determined by these beam formwork components. Beam formwork support is used to support and adjust the height of the formwork for beam to accommodate different beam sizes and requirements.

High-quality aluminium alloy materials are used for beam formwork components to ensure the durability and stability of the formworks. After the concrete solidifies, it can be disassembled and preserved separately for next use.

● Beam formwork components of aluminium

★beam bottom formwork

Beam bottom formwork refers to the structure used in construction and engineering to support and fix the bottom of beams.

1. Load-bearing capacity: Beam bottom formwork is capable of bearing the weight of the beam itself as well as other loads during construction and use. It ensures the stability and safety of the beam by transferring these loads to the supporting structure.

2. Providing support: Beam bottom formwork is connected to supporting structures such as columns and walls to provide stable support for the beam. It evenly distributes the load of the beam and transfers it to the supporting structures.

3. Maintaining shape: Beam bottom formwork helps maintain the geometric shape and dimensions of the beam, preventing deformation or sinking due to applied forces. It provides a stable supporting surface, keeping the beam level, straight, and at the correct height during construction.

★ beam side formwork

Beam side formwork is used to provide support for the sides of the beam and maintain its shape.

1. Enhancing lateral stability of the beam: Beam side formwork increases the lateral stability, reducing the deformation of the beam under lateral loads by providing additional rigidity and support.

2. Increasing the strength of the beam: Beam side formwork can provide additional cross-sectional area, thereby increasing the bending strength and load-bearing capacity of the beam. By increasing the thickness or width of the side panels, the structural performance of the beam can be improved, enabling it to withstand greater loads.

● Advantages of beam formwork of aluminium

Aluminium Formwork for beam and slab is a commonly used supporting structure in construction and engineering projects, made of aluminium alloy material. It is characterized by its lightweight, durability, and adjustability, making it a widely adopted solution in modern construction.

1. Improved construction efficiency: Aluminium slab beam formwork materials are made of lightweight aluminium alloy, which has a lower self-weight, making it convenient for transportation and assembly. Compared to traditional timber beam formwork, it is lighter, reducing labor consumption and accelerating construction progress, thus improving construction efficiency.

2. Enhanced construction safety: Use of beam formwork is stable and reliable, providing excellent load-bearing capacity and seismic performance. It effectively reduces the occurrence of safety accidents, ensuring the personal safety of workers.

3. Environmentally friendly and energy-saving: Compared to traditional wooden formwork, Aluminium beam formwork uses have higher reuse rates and lower maintenance costs. Additionally, aluminium materials are recyclable, reducing construction's impact on natural resources and minimizing waste generation, making it environmentally friendly.

4. Improved construction quality: Aluminium formwork for beam and slab offers excellent flatness and smoothness, ensuring accuracy and precision during the construction process. It provides a stable supporting structure, resulting in uniform concrete pouring and ultimately enhancing construction quality.

● Aluminium beam formwork design calculation

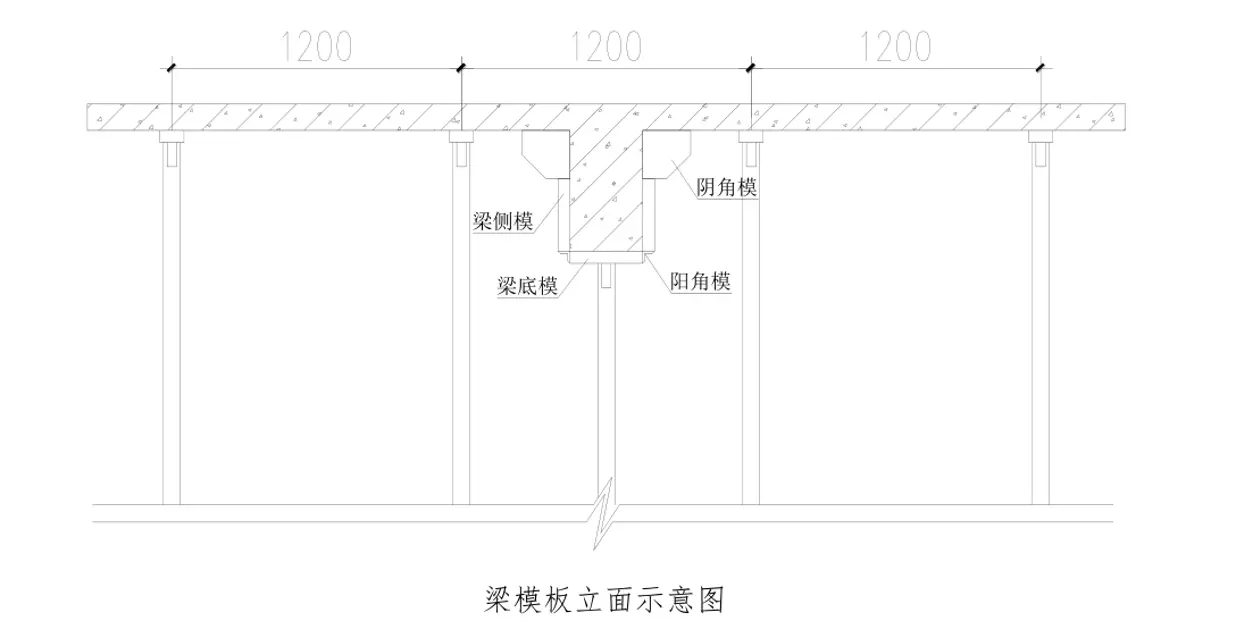

The aluminium beam formwork design adopts a rapid dismantling mode, with a maximum spacing of 1200mm between beam formwork support. The width of the supporting head at the bottom of the beam is 100mm, and the slab formwork length is 1100mm between the supporting heads. The beam bottom formwork and beam side formwork are connected using beam soffit formwork.

● Modification of aluminium ground beam formwork design

When there are changes in the section of beam formwork, it is necessary to contact formwork beam manufacturers for the aluminium formwork fabrication of beam and wall cross-sectional components. The modification of the aluminium formwork can be categorized into the following situations:

1. Variation in beam height

When there is a change in beam height, it is necessary to update the edge beam formwork design according to the drawings, ensuring that the edge beam formwork meets the required height specified in the drawings. The aluminium formwork manufacturer will then process the formwork accordingly. During the construction process, different models of formwork will be used based on the variation in beam height.

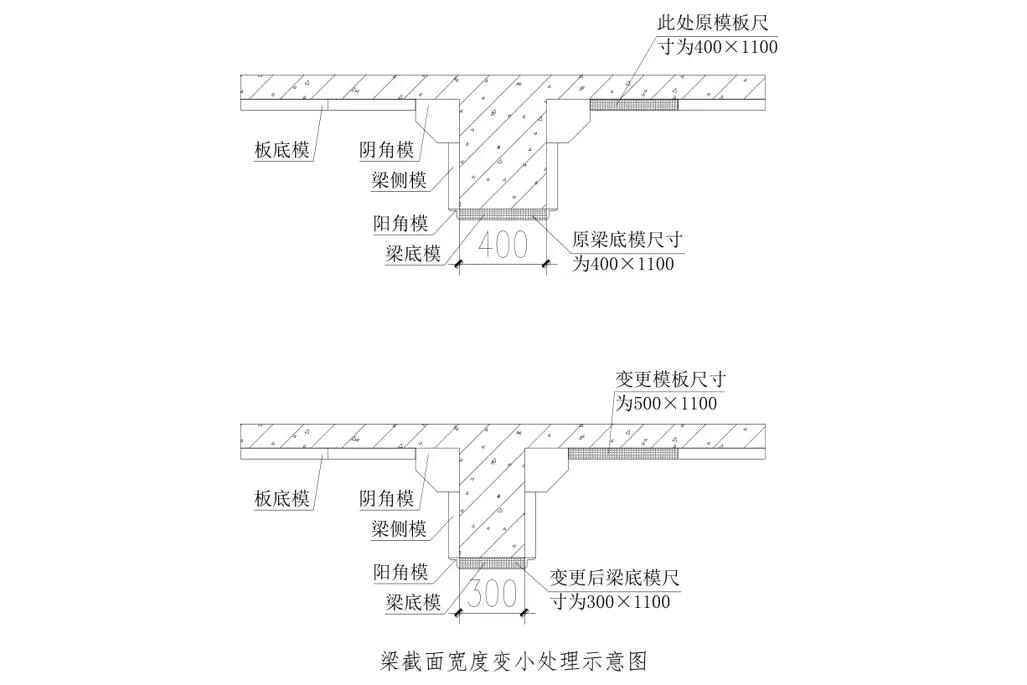

2. Reduction in beam section width

When there is a decrease in beam section width, it is necessary to update the design of the formwork of beam based on the drawings. Example: If the beam width changes from 400mm to 300mm, a new formwork of beam with a width of 300mm should be configured. The original size of the slab formwork was 400mm × 1100mm, and it should now be modified to 500mm × 1100mm.

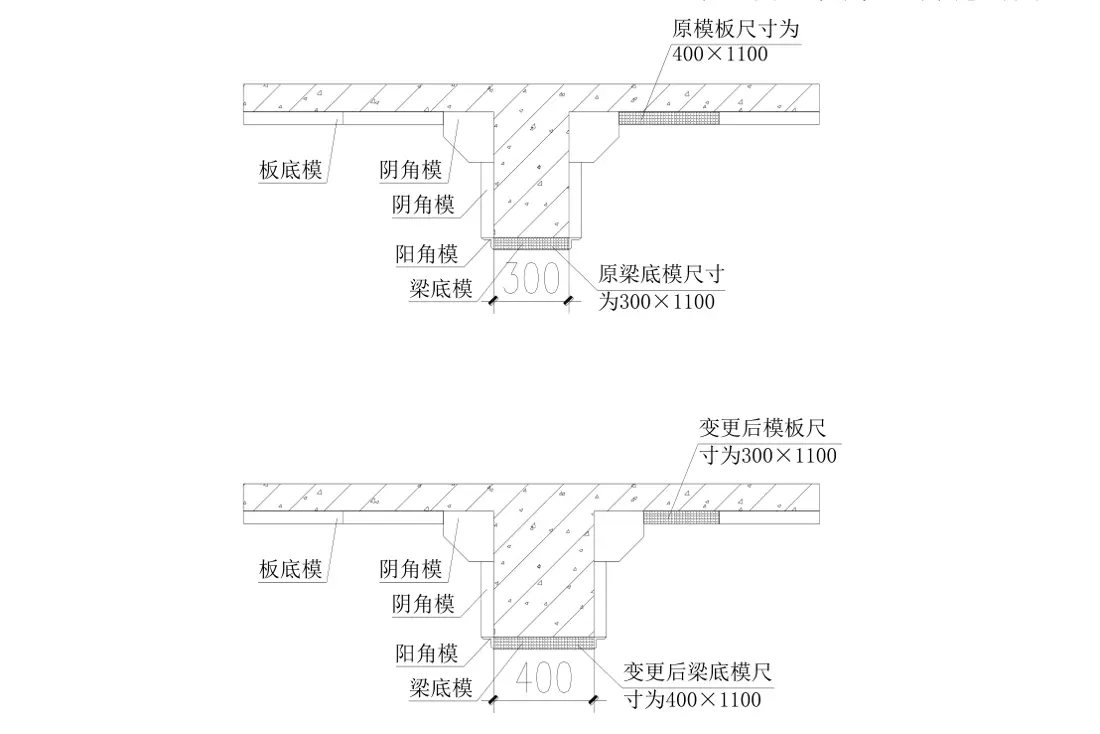

3. Increase in beam section width

When there is an increase in beam section width, it is necessary to update the design of the formwork of beam based on the drawings. Example: If the beam width changes from 300mm to 400mm, a new formwork of beam with a width of 400mm should be configured. The size of the slab formwork was originally 400mm × 1100mm, and it should now be modified to 300mm × 1100mm.

● beam formwork procedure

The assembly of the roof beam formwork mainly consists of the beam bottom formwork, formwork for edge beam, and supports. When assembling the roof beam formwork, it is recommended to initially assemble the beam bottom formwork and supports on the ground, reinforcing them using long dowel pins. Then, the assembled formwork can be installed onto the wall formwork as a unit. Finally, during the installation of the formwork for edge beam, it should be done in a sequential manner following the assigned numbering.

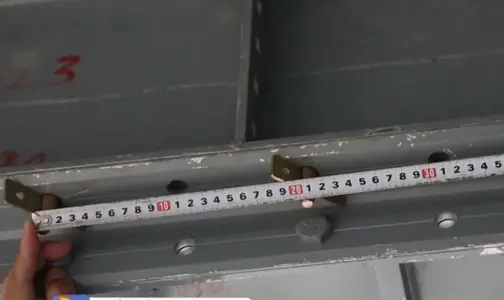

★capping beam formwork strengthening Once the capping beam formwork is assembled, it should be promptly supported using beam formwork support rods. Connect the beam formwork support rod to the beam formwork support head and securely tighten it to prevent any shaking, loosening, or accidental dislodgement of the capping beam formwork. Horizontal dowel pins should be installed at intervals of 250mm. For drop edge beam formwork, ensure that a minimum of three pins are used per sheet. If the beam height exceeds 600mm, the maximum spacing between dowel pins should not exceed 200mm. For beam heights exceeding 800mm, flat ties must be added.

★ Removal of beam girder formwork

1. The removal of beam girder formwork should be carried out after the concrete has reached the design strength. Generally, the side forms of the beam can be removed when the concrete strength reaches 50% and 12 hours have passed since pouring. The bottom formwork of the beam can be removed when the concrete strength reaches 100% and 36 hours have passed since pouring.

2. For formwork for suspended beam, it is necessary to wait for the concrete to reach 100% strength and 21 days to pass after pouring before removing the bottom support rods of the beam formwork.

★ Precautions for beam formwork removal:

1. Prior to removal, it is necessary to install a working platform to ensure safety.

2. The formwork should only be removed when the concrete strength reaches the design strength.

3. Take caution not to loosen or collide with the support rods when dismantling the formwork.

4. Clean the formwork immediately after removal, removing any debris, and applying form release agents promptly.

5. Any formwork that has been deformed or bent during the construction process should be promptly sent to the processing area for correction.

6. Clean, count, and transfer the removed components promptly to the higher floor.

7. Transfer the removed formwork to the upper level through the pre-determined floor openings, and use stairs to transport scattered components.

● Economic Benefits and Environmental Value

★ Reduce Cost

The use of beam formwork can result in various cost savings and benefits.

aluminium materials have a lightweight and high strength, making beam formwork easier to transport, install, and dismantle, thus reducing labor and machinery usage costs.

aluminium beam formwork has a long service life and good corrosion resistance, which eliminates the need for frequent replacement and maintenance, reducing maintenance costs.

The reusability of aluminium beam formwork reduces material waste, further reducing costs.

★ Sustainable Development

aluminium beam formwork exhibits high environmental friendliness and sustainability.

1. aluminium is a recyclable material with high value for reuse. The beam formwork construction can be recycled and reused after the project, reducing the consumption of natural resources.

2. Compared to other materials, aluminium beam formwork generates less waste and pollution during the production process, resulting in relatively minimal environmental impact.

3. The reusability of aluminium beam formwork reduces the demand for raw materials, further promoting sustainable development.

● Knowledge

★ How long to wait to remove formwork for beams?

aluminium beam formwork utilizes a rapid dismantling system, resulting in short beam formwork removal time. The beam side formwork can be dismantled after 12 hours, while the beam bottom formwork can be dismantled after 36 hours. However, during the dismantling process, it is crucial to ensure that the support rods remain in their original positions without loosening. The removal of beam supports can be considered after 21 days. It is important to note that the precise beam formwork removal time should be determined based on sufficient concrete solidification, structural design requirements, and project progress planning. Before conducting any dismantling operations, please consult professional engineers or follow relevant regulations and construction standards to ensure the safety and effectiveness of the procedures.

★ What is the formwork used for beam?

The beam formwork commonly referred to as beam formwork concrete is a temporary structure used to support and shape concrete during the construction process of beams. It determines the shape, size, and position of the beams.

Beam formwork concrete consists of various beam formwork components, including beam bottom formwork and beam side formwork, as well as beam formwork support, which are assembled to achieve the desired shape. aluminium beam formwork concrete offers adjustability and reusability, making it suitable for various beam structures. During the concrete pouring and curing process, it is essential to ensure proper alignment and support to maintain the desired shape and structural integrity of the beams.

If you want to know more about formwork construction, such as aluminium formwork construction safety requirements, don't hesitate to contact us.

● Recommended

+86 19112905173

+86 19112905173