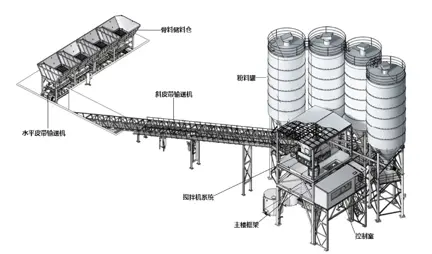

HZS120 Stationary Concrete Batching Plant

● Concrete batching plant components

HZS120 concrete batching plant is a large sized stationary concrete batching plant, The complete HZS120 concrete batching plant equipment includes double horizontal shaft mixer, material batching machine, cement silo for concrete batching plant, screw conveyor and microcomputer control room. This type of concrete batching plant can produce plastic concrete, dry hard concrete and many other kinds of concrete.

HZS120 compact concrete batching plant has high production efficiency and short mixing time. The theoretical productivity of HZS120 concrete batching plant equipment is 120m³/h, the power of the mixer is 74KW, with 2000L nominal capacity of the mixer. The batching machine has 2 raw material hoppers, the batching capacity is 3200L. It is equipped with 2 of 200T cement silo for concrete batching plant,the capacity of powder silo: cement weighing range and accuracy is (0~1200)±1%kg, admixture weighing range and accuracy is (0~50)±1%kg, aggregate weighing range and accuracy is 4*2000 ±2%, the discharging height is 3.8m, total power is 145KW, to meet the production demands.

HZS120 ready mix concrete batching plant is widely used in the large and medium scale building constructions, roads and bridges, and precast plant which produce the concrete products. It is an ideal mixing equipment for the commercial concrete production.

● Components of concrete batching plant

Mixing system

Equipped with JS2000 forced double horizontal shaft mixer, the mixing arm is made of high wear-resistant alloy which make it has high wear resistance and strong impact resistance, Strong sealing technology to avoid the leakage. The mixer no need inject the lubricating oil, save the cost of concrete batching plant, and has no pollution to the concrete. It is suitable for the large-scale construction, commercial concrete companies, etc.Batching system

HZS120 ready mixed concrete batching plant is equipped with the PLD3200 batching machine. The raw materials are feeding through a belt conveyor. It has individual material weighing and cumulative material weighing total two weighing method. It adopts electronic weighing, microcomputer control, digital display, and wired remote control operation, to make it has advantages such as accurate weighing, high batching precision, fast speed, strong control function, and easy operation.Control system

This precast concrete batching plant adopts imported components, has excellent performance; it integrate the intelligent control, automatic control and manual control; it has concrete ratio storage function, can gap compensation automatically, and over-scale and under-scale alarms and correction; it has functions such as operation monitoring, data cloud storage, and printing.

Conveying system

The powder conveying adopts a fully sealed device; the discharge port and the metering hopper adopt a soft link, which does not affect the metering accuracy; the material receiving port is a universal ball joint, the angle deviation can be adjusted; the gap between the spiral blade and the conveyor tank is very small, and the transmission efficiency is high.Material storage system

The upper and lower parts of the cement silo for concrete batching plant are each equipped with a material level gauge. There is an air blowing arch breaking device at the cone of the silo to prevent the powder from arching. It uses a solenoid valve to control the release of compressed air to break the powder arch. It also can be designed as a chip shaped cement silo, easy to transport.Metering system

The powder, water and admixtures are all measured by electronic scales; with high batching precision and measurement accuracy; the cement measuring hopper is hung on the frame by a sensor, with a stable structure and high reliability; the water metering device uses a water pump to unload; the admixtures measure bucket is metered by a single hanging point sensor.

● Concrete batching plant specification

| Concrete batching plant equipment | Concrete batching plant Model | HZS120 |

| theoretical productivity (m³/h) | 120 | |

| discharging height (m) | 4 | |

| Working cycle time (S) | 60 | |

| Dimension (mm)(L*W*H) | 55885×20200×21600 | |

| Total power (kw) | 210 | |

| Mixer | Model | JS2000 |

| Batching machine | Model | PLD3200 |

| Pneumatic system | Air compressor model | 1.8-7 |

| Rated exhaust volume (m³/min) | 1.67 | |

| Rated exhaust pressure (MPa) | 0.8 | |

| Motor power (kw) | 15 | |

| Weighing system | Aggregate weighing accuracy range (kg) | ± 2% |

| Cement weighing accuracy (kg) | ± 1% | |

| Water weighing accuracy (kg) | ± 1% | |

| Admixture weighing accuracy (kg) | ± 2% |

● HZS120 compact concrete batching plant application

The theoretical concrete batching plant capacity of HZS120 is 120 m3/h. The complete concrete batching plant equipment includes JS2000 forced double horizontal shaft mixer which has the 2000L nominal capacity, PLD3200 batching machine, cement silo, screw conveyor, belt conveyor, microcomputer control room. HZS120 can be used as different types of concrete batching plant such as dry concrete batching plant, wet mix concrete batching plant etc. to produce various types of concrete. This concrete batching plant machine has fast mixing speed and excellent mixing effect, it can meet the requirements of large quantity of concrete, and can realize concrete proportioning according to different construction requirements to ensure the quality and stability of concrete. so the HZS120 type of concrete batching plant is widely used in various large scale engineering construction projects, such as road construction, bridges, tunnels, reservoir construction etc. which has large demands of concrete.

● The area required for concrete batching plant HZS120

The area required for concrete batching plant main based on the concrete batching plant specification and concrete batching plant components, and also concrete batching plant manufacturers. Even the components of concrete batching plant are the same, the area required for concrete batching plant HZS120 will be different due to the different concrete batching plant manufacturer. The belt conveyor type of concrete batching plant HZS120 is placed in “L” shaped pattern, takes an area of approximately (length × width): 55 × 20 meters. It is noted that, the complete concrete batching plant building also requires for other supporting equipment in addition to the concrete batching plant machine, as well as the places for concrete batching plant wastewater treatment, gravel storage and so on. So the total area required for a medium sized concrete batching plant is approximately 6600 square meters.

● Concrete batching plant capacity and price of HZS120

HZS120 stationary concrete batching plant is also called “2m³ concrete batching plant. It has high production efficiency and short mixing time, discharge once each 60s, 2m³ concrete each time, the theoretical concrete batching plant capacity of HZS120 is 120 m3/h, and the actual concrete batching plant capacity is around 100 m3/h due to the influence of external factors such as the material suppling and worker’s concrete batching plant operation skill level etc. The total power is 230Kw, due to the different concrete batching plant specification and configuration, the stationary concrete batching plant price is also different. The HZS120 automatic concrete batching plant price is around 120,000 to 180,000 dollars, please feel free to contact us for accurate quotation.

● Precautions for concrete batching plant operation(concrete batching plant operation manual)

Precautions before starting the concrete batching plant

1. Prepare qualified sand, gravel, aggregates, etc. according to the standard concrete batching plant specification. The materials exceeding the standard scope can not be used.

2. Before using the concrete batching plant equipment, all meters must be adjusted to zero according to regulations.

3. Check the oil level and oil quality of the gear box, make sure the oil level is suitable and the oil is clean.

4. Check and pay attention to the safety of electrical appliances to prevent electrical components and wires from getting damp and damaged.

5. Check the weighing device and make sure it can be used normally. The rubber sleeve connected to the weighing hopper should not be stressed, to avoid affecting the weighing accuracy, and the error cannot exceed 1%.

6. Make sure the lifting protector can brake sensitively and the safety pin of the lifting bucket is normal. If someone is working under the lifting bucket, be sure to lock the lifting bucket with the safety pin.

7. When starting the concrete batching plant machine, should check whether the rotation direction of rotating components of concrete batching plant is the same with the direction of the marked arrow.

8. The concrete mixer should be covered with a lid before starting. When working at night, there should be adequate lighting.

9. After the concrete batching plant hopper is raised, please do not stay under the hopper, and please do not use the concrete batching plant hopper to lift heavy objects.

10. It is strictly forbidden to operate the water pump for mixing without water.

● Precautions during the working of concrete batching plant

1. Adjust the ratio of sand and gravel, the overshoot amount, the feeding sequence and the mixing time according to the moisture ratio.

2. The feeding system should prevent aggregate from entering the operating mechanism of concrete batching plant machine. Generally, sand and cement cannot be fed in the same pipe trough.

3. Add water while feeding raw materials to reduce dust flying.

4. Feeding can be done once or multiple times. Once feeding means to put the materials into the mixer according to a certain process sequence, kindly note, cement can not be put in first to avoid cement sticking to the shaft. When feeding once, in order to prevent the cement from being wrapped by water and forming cement balls, should mix the cement and sand to disperse the cement before pouring water. Multiple feeding and mixing of concrete is also called shell concrete. Its feeding operation is relatively complicated and needs to be realized in special treatment in the concrete batching plant.

5. Please keep paying high attention to various instruments, if has any abnormal phenomenon, should adjust and deal in time.

6. Due to the mortar will stick to the inside of the mixer when the first tank, should consider whether to compensate by adding sand, cement and reducing stone.

7. Please do not do the concrete batching plant repair, maintenance, lubrication, fasten etc. during the concrete batching plant operation. If the hopper is stuck by some objects, please don not pull by force, at this time should discharge 50% materials by manual from the discharging device. Check out the stuck reasons and then restart.

8. After the discharging is completed and the discharge hopper is closed, the feeding can be carried out again.

9. When there is a sudden power outage or a malfunction causes shutdown, please pay more attention to the concrete batching plant operation and clean the concrete in the mixer in time.

Precautions after the working of concrete batching plant

1. Before stop the concrete batching plant equipment, should discharge all the concrete, add some stones and water keep mixing for some minutes to clean the mixing tank.

2. In cold weather concrete batching plant can not left water in the water supply system, clean the accumulated ash and stuck concrete inside of the concrete batching plant machine, and clean the construction site

3. Cut off the power supply and lock the electrical box. Check each lubricating part and add oil accordingly.

● The maintenance of concrete batching plant equipment

The maintenance of concrete batching plant equipment is divided into maintenance per shift and graded maintenance according to prescribed periods.

1. Maintenance per shift (routine maintenance): refers to the maintenance work before, after and during the working of concrete batching plant. The content is “inspection”, such as checking the completeness of concrete batching plant machine and parts of concrete batching plant, oil volume, water volume, indication values of instruments, the working condition of control devices (such as steering, braking, etc.), the solidity of key concrete batching plant parts, and whether there are leaks of oil, water, gas , electricity and other abnormal phenomenon, whether it is necessary to add lubricating grease, cooling water, etc. to ensure the normal concrete batching plant operation and production. Maintenance is performed by concrete batching plant operator during each shift.

2. First-level maintenance: The focus of this maintenance is lubrication and tightening. Check and tighten the external connecting parts of concrete batching plant, add lubricating oil and grease, clean the filters or replace the filter elements as required.

3. Second-level maintenance: This maintenance is focus on the inspection and adjustment. In addition to do all contents of first-level maintenance, also need to check the working condition of the power device, control system, transmission system, steering system, brake system, speeding system and walking etc. from outside. If necessary, should do adjustment and troubleshooting accordingly.

4. Third-level maintenance: This maintenance is focus on eliminating the hidden dangers. In addition to do all the contents of second-level maintenance, we should inspect the main parts of concrete batching plant. If necessary, partially disassemble the corresponding concrete batching plant parts to check the fastening, gaps and wear situation of the internal parts, to find and eliminate the hidden dangers. Please do not disassemble in large scale to avoid damaging the concrete batching plant parts.