Block and Brick Making Machine Manufacturer-Yansumi

We provide best block and brick making machines with great ideas to develop your block and brick production business.

Ladrillos maquina para hacer ladrillos de cemento completamente automatico

● Block Making Machine

◆ Clay Brick Making Machine

◆ Concrete Block Making Machine Click To See Catalog

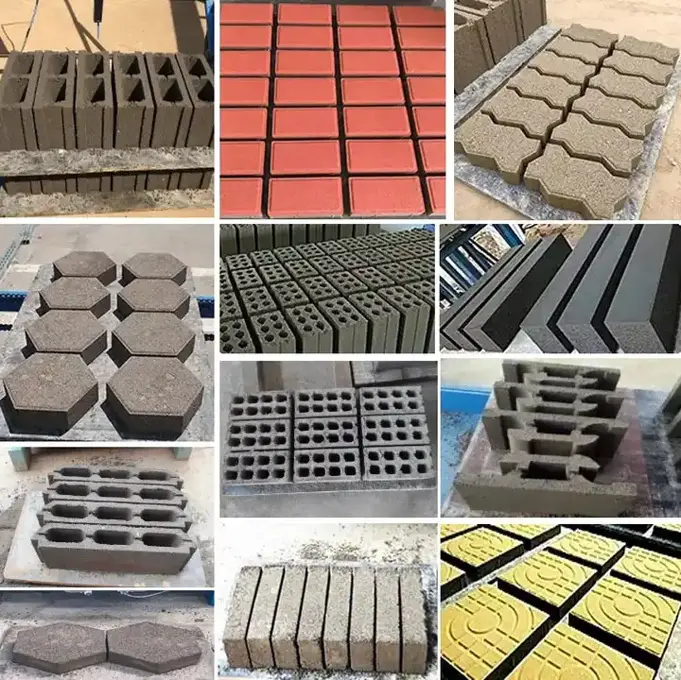

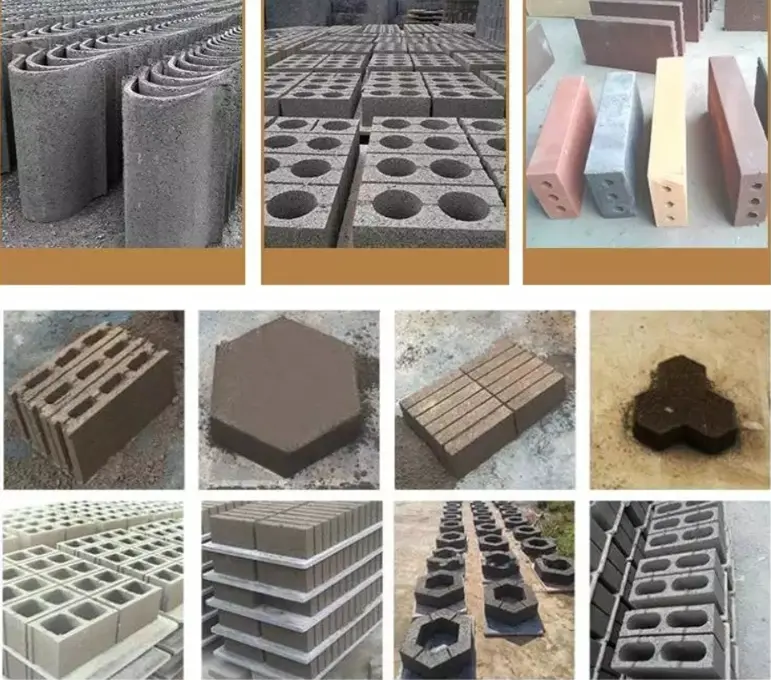

Our brick making machines can be divided into two main categories: no burning brick machine and clay brick making machine. The no burning brick machine mainly uses raw materials such as sand, stone, stone powder, cement, fly ash, slag, steel slag, coal gangue, and construction waste to produce various sizes and types of hollow blocks, standard bricks, porous bricks, paving bricks, plaza bricks, lawn bricks, slope protection bricks, etc. While the clay brick making machine mainly uses clay, gangue, shale, fly ash, etc. as raw materials. Our brick machines are rich in models, reliable in quality and affordable in price, and can meet the needs of users with different production scales and brick-making purposes. Our products mainly include:

● Block brick making machine

● Solid brick making machine

● Hollow brick making machine

● Pavement brick making machine

● Cement brick making machine

● Concrete brick making machine

● Flyash brick machine

● Clay brick making machine

● Mud brick making machine

● Soil brick making machine

● Vacuum brick machine

● Production lines and auxiliary equipment

● Application of brick machine

Brick machines are widely used in the construction industry and municipal engineering for producing various types of bricks. Some common types of brick machines include clay brick machine, mud brick machine, cement brick machine, concrete brick machine, flyash brick machine, ash brick machine, and sand brick machine. These brick machines are often used as block brick machine, hollow brick machine, paving brick machine, adobe brick machine, red brick machine, soil brick machine, etc., and they are widely used in various industries. Here are some application scenarios of brick machines:

● Construction projects: Brick making machines are widely used in the construction industry for producing different types of bricks such as red bricks, concrete bricks, hollow bricks, etc. These bricks can be used in residential buildings, commercial buildings, industrial buildings, and other construction projects.

● Municipal engineering: Brick molding machines also play an important role in municipal engineering. For example, they are used for road pavement, sidewalk construction, drainage system development, etc. The bricks produced by brick molding machines can meet the material requirements of municipal engineering projects.

● Garden landscaping: Bricks produced by brick maker machines can be used in garden landscaping design, such as courtyard paving, flowerbed borders, pathway construction, etc. These bricks are beautiful in appearance and durable.

● Rural construction: In rural areas, brick maker machines are commonly used for producing various bricks, such as clay bricks, antique bricks, etc. These bricks can be used in rural housing construction, agricultural water conservancy projects, etc.

● Eco-friendly construction: With increasing attention to sustainable development and eco-friendly construction, ecological brick making machines are gradually being used to produce environmentally friendly bricks, such as recycled bricks, lightweight bricks, etc. These bricks can reduce dependence on natural resources and reduce harm to the environment.

In conclusion, brick machines have wide applications in construction, urban infrastructure, garden landscaping, and environmental protection. Brick manufacturing machines improve production efficiency, reduce labor costs, and can produce high-quality and high-strength bricks to meet the needs of different fields. Due to the wide range of uses, brick machines become a good investment. You can choose a manual brick machine, semi automatic brick making machine, fully automatic brick making machine, small scale brick making machine, maxi brick machine, hand brick making machine, hydraulic brick making machine, etc., to invest according to your brick making purposes, budget and production requirements.

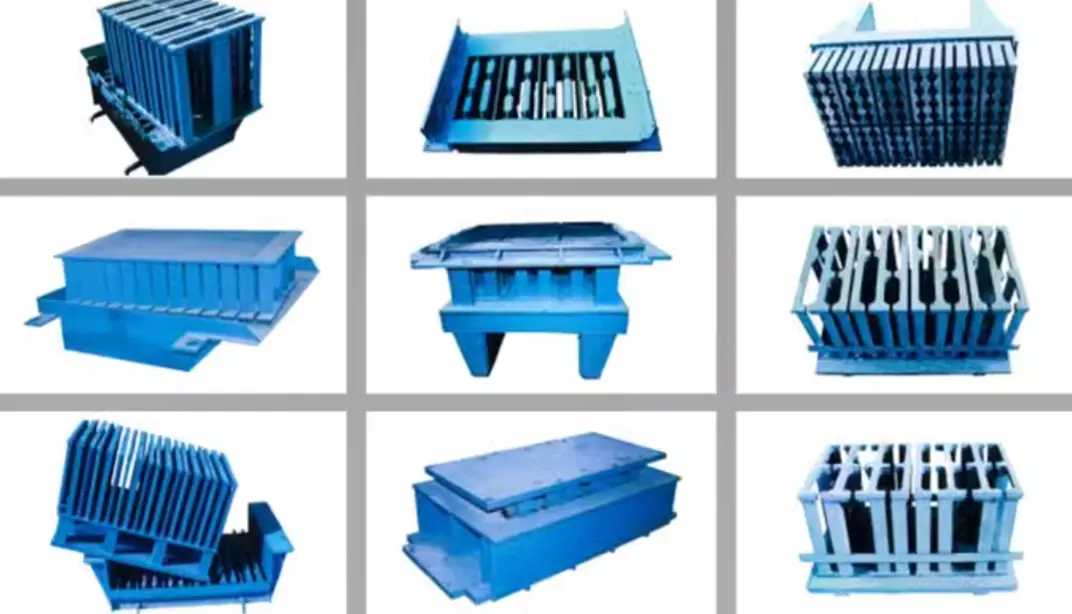

● How to maintain brick making machine moulds

Brick making machine moulds are one of the most important components for brick production. By replacing different moulds, you can produce bricks with various sizes and shapes on the same brick machine, this can greatly reduces your investment and creates more value. As frequently used accessories, the brick making machine moulds may suffer from rust and wear, so it is important to properly maintain them during daily use. As professional brick machine manufacturers, we’d like to share some maintenance tips for brick making machine moulds.

In summary, here are some precautions for using and storing cement brick making machine moulds:

1. Brick making machine molds are made of steel, when they encounter water, salt, alkali and other impurities, they will inevitably be corroded. So it is necessary to clean the stains on the moulds in time after use.

2. During use, the brick making machine moulds subject to friction from different raw materials, which will cause wear and tear, so it is important to do appropriate external protection, such as painting.

3. Regularly check the punch head of the brick making machine for sale, properly weld the cracked positions.

4. Many brick making machine moulds have corner springs. Please store them properly, because different brick machines may have different design of these springs.

5. When storing the brick making machine moulds, try to keep them separate to ensure proper air circulation and prevent rusting.

Kindly note, proper maintenance of brick making machine moulds is helpful to prolong their service life and ensures the quality of the bricks produced. Regular cleaning, maintenance and inspection are basic works to maintain brick machinemold performance and durability.

● Pressure Block Maker Related Supporting Equipment

◆ Extrusion Block Making Machine

● Extrusion Block Maker Related Supporting Equipment

● Why choose us?

√ Diverse product range: We offer manual, hydraulic, and automatic brick making machines, along with related auxiliary equipment such as mixers, feeders, stackers, crushers, and cutters, providing comprehensive solutions for our customers.

√ Advanced manufacturing technology: We employ advanced manufacturing processes and technologies to ensure precision and consistency during the production, ensuring that our brick making machines and auxiliary equipment have efficient and stable performance to meet the diverse production needs of our customers.

√ High-quality materials: We use high-quality materials and components in manufacturing equipment, which helps to ensure long-term stability and reliability. This means that customers can trust your equipment to maintain high-quality processing capabilities over the long term, reducing maintenance costs and improving production efficiency.

√ Customization capability: We can provide personalized customization of brick making machines and auxiliary equipment according to the specific needs and requirements of customers, ensuring maximum satisfaction of their production needs.

√ Comprehensive pre-sales service: We have a professional pre-sales consulting team that can provide customers with detailed product knowledge and solutions, helping them select the most suitable equipment and auxiliary equipment for their production needs.

√ Comprehensive pre-sales service: We have a professional pre-sales consulting team that can provide customers with detailed product knowledge and solutions, helping them select the most suitable equipment and auxiliary equipment for their production needs.

√ Efficient after-sales service: We have established a comprehensive after-sales service system with a professional technical team and after-sales service personnel who can respond to customer needs in a timely manner, ensuring the proper operation and maintenance of the equipment.

√ Quality assurance: We are committed to providing high-quality, reliable products through strict quality control and testing, ensuring that customers receive trustworthy brick making machines and auxiliary equipment.

√ Long-term partnership: We focus on establishing long-term stable cooperation with customers, aiming for mutual development and success, providing continuous support and service to customers.

● Types of block moulding machine

The types of block moulding machine are diverse. Here we introduce the main classification methods and block moulding machine categories:

1. According to different raw materials used to make blocks, the block moulding machine can be divided into cement block moulding machine / concrete block moulding machine, fly ash brick making machine, and clay brick moulding machine.

2. According to the automation grades, they can be divided into:

● Manual block moulding machine / hand block moulding machine. Manual block moulding machine relies entirely on manual operation for brick production and is suitable for small-scale blocks production.

● Semi automatic block making machine has certain automation functions, significantly reducing labor intensity and technical requirements. Semi automatic block making machine requires some manual operation and is suitable for small-scale brick production, such as individual projects, small construction projects, or personal entrepreneurship.

● Automatic block moulding machine can work automatically from raw material processing to brick forming and conveying, and is mainly used in large-scale brick production areas such as construction, road paving, municipal engineering, and landscaping. However, the fully automatic block making machine price is much higher, and it has high requirements for operation skills and maintenance, so the automatic block moulding machine is usually used by professional production enterprises or large construction projects.

3. According to the output capacity, the block moulding machine for sale can be divided into maxi brick block making machines, medium size brick moulding machines, and small block making machines. Manual brick moulding machine is generally a mobile block moulding machine, which is also a small scale brick machine. Semi automatic brick making machine also belongs to small scale brick machines with a daily output of several thousands blocks. While the automatic block moulding machine, depending on the machine output capacity, includes both small brick moulding machine and large brick moulding machine for sale.

These brick machines correspond to various users with different production scales and output requirements.

● How to choose block moulding machine

In the previous content, we introduced the main types of block moulding machines. Now let's briefly introduce how to choose the right block moulding machine based on their characteristics.

1. Cement brick moulding machine / concrete block moulding machine and fly ash brick making machine typically use stone powder, fly ash, slag, mine tailings, crushed stones, sand, and water as raw materials for brick making. They are commonly used in areas which are rich in industrial and mining waste.

2. Clay brick moulding machines primarily use clay as the main raw material. They are suitable for regions with abundant clay resources and no policy restrictions.

3. Manual block moulding machine (or hand block moulding machine) is a brick making machine that relies on manual operation. It does not have an automated control system. Operators have to manually handle the processes such as raw material loading, mixing, pressing, and forming, and remove the finished bricks manually. Manual block moulding machines is high flexibility which make them easy to transport and move. They have lower investment costs. Hand block moulding machines are suitable for small-scale brick production and can be used in various construction sites or locations. However, hand block moulding machines have lower production efficiency, making them only suitable for individual projects, rural areas, or personal entrepreneurship scenarios.

4. Semi-automatic block moulding machines are equipped with some automation control devices that enable automated operations for basic processes such as pressing, forming, and feeding of bricks. This improves production efficiency and quality stability. However, semi-automatic block moulding machines require some manual intervention from operators, such as manually loading raw materials, removing finished bricks, and performing simple maintenance and debugging tasks. They have relatively limited production efficiency and output capacity, making it hard to meet the demands of large-scale brick production. Semi-automatic brick moulding machines are more suitable for those investors who want to build a brick making factory but lack experience and funds.

5. Automatic block moulding machines are highly automated brick production equipment, all processes including raw materials supplying, mixing, pressing, forming, and stacking are doing automatically. The fully automatic brick molding machine for sale adopts PLC computer control system that can accurately control various process parameters such as pressure, temperature, time, etc., to ensure that the quality and specifications of the bricks can meet the required standards. It can continuously produce bricks and adjust the speed and output of the production line as needed. Fully automatic brick making machines are widely used in large-scale brick production fields. The investment cost of block moulding machine is high, and the operation technique and maintenance requirements are also high, so the automatic moulding block machine are usually used by professional production enterprises or large construction projects. Fully automatic block moulding machines are suitable for users who want to invest in large brick factories to obtain high-profit returns.

Manual block moulding machines and semi automatic brick making machine s are both small-sized brick machines. Some small automatic block moulding machines also belong to the category of small-sized brick making machines, such as our QT3-15, QT4-15, QT5-15 block making machines, their production output generally ranging from hundreds to thousands blocks per hour, depending on the size and type of the bricks and brick making machine models too. Our QT6-15 block making machine, QT8-15 brick molding machine are medium-sized brick machines, with a production output generally ranging from 55,000 to 80,000 solid bricks (240*115*53mm) and 10,000-15,000 hollow bricks (390*190*190mm). QT10-15 block making machine and QT12-15 are large-sized brick machines that can produce 110,000-120,000 solid bricks and 16,000 hollow bricks. They are mainly suitable for enterprises and organizations that require a large quantity of bricks and for the investors who are interested in the field of building materials production.

Please kindly note that all types of block moulding machine mentioned above can produce bricks of various sizes and shapes by changing the molds. You only need to consider your budget, production site size, brick output requirements, etc., to decide which specific block moulding machine to choose. If you still have doubts about the brick making machine selection, please feel free to contact us for further communication.