Hollow block maker machine

Model of hollow block machine for sale: 4-35A(2B)

The hollow block maker machine is also called cement hollow block machine and the finished bricks do not need to be fired. The hollow block machine for sale adopts the semi automatic control system to achieve the highly effective making brick. The hollow block making machine has the advantages of a compact structure, mechanical transmission, and low failure rate, so it has a wide application in the construction, forestry, rural, and other construction fields.

◆ Hollow block maker machine features

-

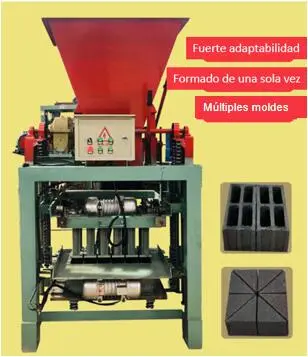

The body of the hollow block machine is made of high strength steel materials. It has the features of high compressive strength, strong deformation resistance, good stability, solid and durable.

-

The hollow block molder machine adopts a powerful electric motor and has the advantages of stable working and long service life.

-

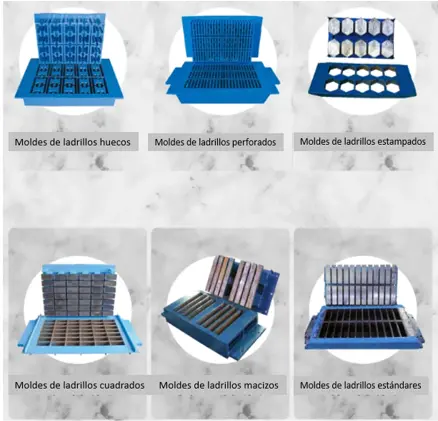

The hollow block manufacturing machine can customize various molds. The different molds can produce various shapes and specification products to meet different requirements of the customers.

◆ Automatic hollow block machine parameters

| Model | 4-35 A(2B) |

|---|---|

| Size(L*W*H) | 1300x 1200x 1600 MM |

| Moto power | 7.5(KW) |

| Weight | 0.7 T |

| Voltage | 200V-380V |

| Number of operators | 1-2 |

| Raw material | Sand, gravel, fly ash, slag, gypsum powder, etc. |

◆ Small hollow block making machine output

| Specification(mm) | Number(pieces) |

|---|---|

| 390*190*190MM | 4 |

| 390*240*190MM | 3 |

| 390*150*140/190MM | 5 |

| 390*115*190MM | 6 |

| 240*115*53MM | 21 |

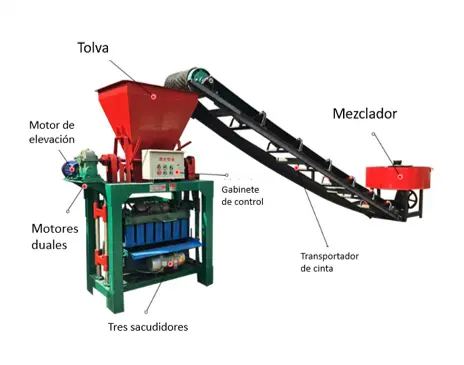

◆ Fully automatic hollow block making machine production line

The fully automatic hollow block making machine includes the host and control cabinet, the price is 4500 USD to 9500 USD. The production lines include the hollow block mixer machine, conveyors, hydraulic hollow block machine, pallets, etc and the price is 8000USD to 30000USD.

◆ Hollow block making machine applications

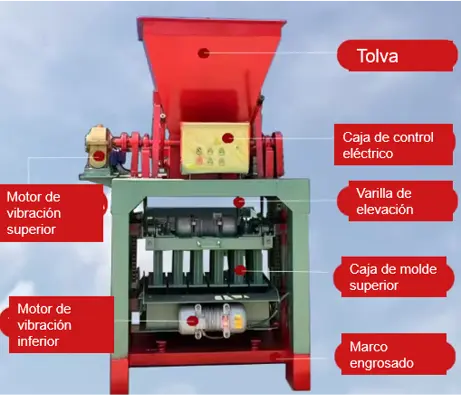

The hollow block making machine is also called cement hollow block machine or concrete hollow block making machine and is professional equipment for making concrete bricks. The hollow block forming machine consists of the electric motor, reducer, feeding system, pressure head, and crank link mechanism. The electric motor drives the reducer and the reducer drives the main shaft of the equipment to rotate. The crank link mechanism converts circular motion into up and down linear motion of the stamping mechanism. and the pressure head of the stamping mechanism was automatically pressed into the mold filled with a mixture. And then, after the bricks are formed, we can use manual or mechanical transmission to remove the bricks.

The hollow block machine automatic can use various materials as raw materials, such as stone, sand, rubble sand, fly ash, expanded particles, etc. It can meet various applications and produce various specification bricks, such as porous bricks, hollow bricks, and road bricks. The hollow block machine design is advanced and adopts the plc control system and hydraulic system to ensure the stable working of the machine. The hollow block automatic machine also has the advantages of reliable performance, simple operation, small errors, and easy maintenance, so it has wide application in the construction of buildings, roads, squares, gardens, landscaping, parking lots, and road surfaces.

◆ How to build a hollow brick factory?

1. Production site

The small hollow brick factory produces the hollow brick 1.5 million pieces every year, the scale is relatively small. So, the production equipment can use a semi automatic hollow block machine and need 3 to 4 workers to produce, The factory requires 2-3 acres of land.

The medium hollow brick factory produces the hollow brick 2.3 million to 4.2 million pieces every year, we can adapt the automatic hollow block making machine, it needs 5-6 workers and the factory requires 4-6 acres of land.

The large hollow brick factory produces the hollow brick 8 million to 10 million pieces every year, the large hollow block molding machine can be selected and it needs 6 workers at least. The factory requires 8-10 acres of land.

The scale of the hollow brick factory is determined by the output of automatic hollow block machine, including the daily production output and bricks maintenance cycle, as well as raw material storage.

2. Production equipment

For the small hollow brick factory, we only need to purchase one piece of production equipment, and the other operation can be completed manually, so the hollow block machine cost is low.

For the large hollow brick factory, we recommend adopting the fully automatic hollow block making machine to ensure the quality and strength of the hollow bricks. Except for the fully automatic hollow block making machine, we also need to buy the supporting equipment, such as an electronic batching machine, hollow block machine mixer, conveyor, fully automatic plate feeder, fully automatic plate unloader, distributor, fully automatic palletizer, batching warehouse, forklift, forklift, etc.

◆ Hollow block machine types

The hollow block making machine can be divided into different types according to the specifications, performance, etc.

According to the different specifications, the hollow block machine can be divided into small hollow block making machine and large hollow block molding machine.

The small hollow block making machine has low requirements for the raw materials, in general, the two materials can be produced. It can replace different molds to produce different brick shapes and is suited for self-employment. So, these machines getting more and more popular in small-scale entrepreneurial groups in rural and urban areas.

The large hollow block molding machine is suited to produce standard bricks, hollow bricks. it can automate making bricks and reduce time and labor costs. So, it is suited for large mass production.

According to the degree of automation, the best hollow block machine can be divided into automatic hollow block making machine, semi automatic hollow block machine, and manual hollow block machine. The automatic hollow block making machine has high production effectiveness and the automatic hollow block making machine price is high. The production effectiveness of the semi automatic hollow block machine is slow, but the semi automatic hollow block machine price is cheaper. The production speed of the manual hollow block machineis the slowest, and the production quality is difficult to guarantee.

● Hollow block molding machine wiring and operation

The hollow block moulding machine belongs to the semi automatic production machinery. The wiring needs to be carried out before production. Let me show you the wiring process and operation sequence.

Hollow block molding machine wiring

1. Connect the power cord: Connect the power cord to the air switch of the electrical cabinet.

2. Wiring: The machine has been debugged, just follow the installation instructions and connect the wires.

Hollow block molder machine operation sequence

1. Turn on the power.

2. Put the raw materials into the molds.

3, Pull the handle down to insert the pressure head into the mold.

4. Turn on the up and down vibration motor and vibrate for 5-8 seconds.

5. Turn off the vibration motor and raise the mold at the same time.

6. Use a wheelbarrow to roll out finished bricks.