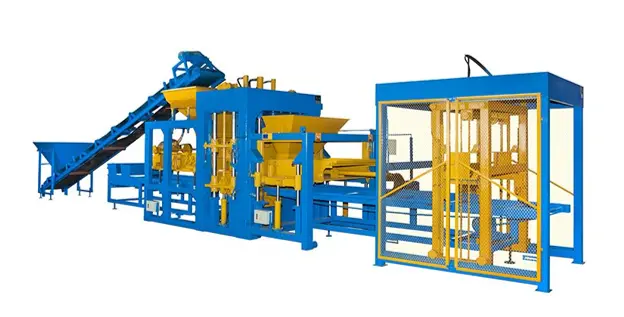

4-35 type small brick making machine

The 4-35 type small brick making machine is a professional mechanical equipment to produce bricks with industrial and construction solid waste such as fly ash, stones, sand, mountain sand, ore powder, and slag as raw materials Brick making machine is mainly used for producing cement bricks and other building materials in various sizes and shapes. This small brick making machine is a semi automatic brick making machine with small dimensions, making it relatively easy to transport and install. It mainly relies on manual operation and offers advantages such as low investment and quick results. Although it is in small size, this simple brick making machine provides a wide range of functions and can use various raw materials to produce different types and sizes of bricks. This brick making machine for sale has very extensive application, including in the fields of construction, roads, and landscaping. It is a cost-effective concrete brick making machine.

● Features of semi automatic brick making machine

1. The semi automatic brick making machine has a simple structure and is easy to operate. The workers can operate directly after simple training.

2. Semi automatic cement brick making machine adopts an excellent enlarged reducer, the key rotating parts are bearings, and the machine frame is made of thickened square steel. The four-column guide ensures accurate positioning, greatly improving the quality of the formed brick.

3. The brick making machine molds are made of high-quality wear-resistant steel and be special treated to enhance their durability and service life.

4. A small cement brick making machine can be equipped with multiple sets of brick making machine moulds, so you can produce various type and size bricks by simply changing the molds.

5. The operation of the semi automatic brick making machineonly requires 2-3 people, reducing production costs.

6. The semi automatic brick making machine has stable performance, no noise pollution, and can operate without faults for a long time.

● Small brick making machine parameters

| Product name | 4-35 small brick making machine |

|---|---|

| Power | 4.8KW |

| Bricks size | 390*190*190mm(hollow brick) |

| 500-600 per shift (8 hours) | |

| Production capacity | 500-600 per shift (8 hours) |

| Capacity per mold | standard brick 21pieces/pallet |

| hollow brick 4pieces/pallet | |

| Forming time | 45 seconds/time |

● Semi automatic brick making machine} details

-

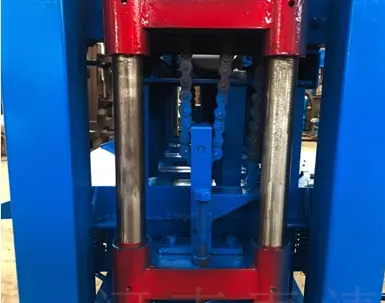

Stroke column

The semi automatic brick making machine} adopts a four-column structure, ensuring accurate positioning. The brick making machine moulds} are balanced and stable, improving the density of the blocks and providing an attractive forming appearance. -

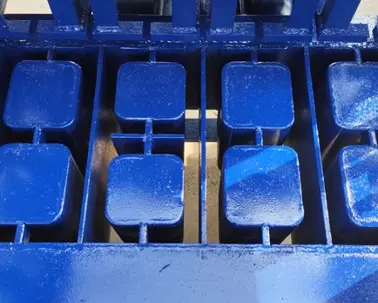

Lower mold box

Brick making machine moulds} can be customized according to customer requirements, One machine can be equipped with a variety of molds, and can produce different sizes and shapes bricks by changing the molds. This brick making machine china} can save investment for you. -

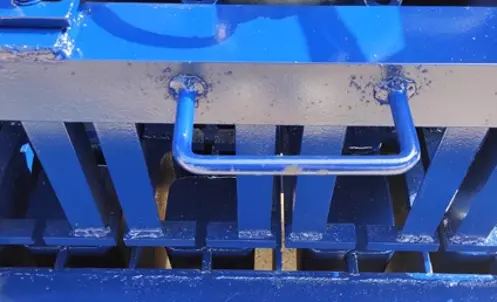

Upper mold pressing head

The pressing head moves vertical, making it easy to feed, maintain and clean.

-

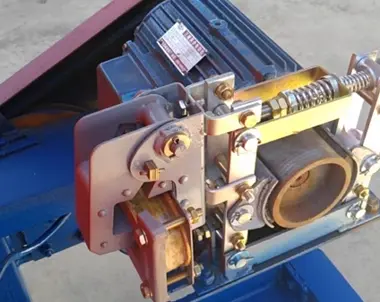

Lifting motor

The chain drives the semi automatic brick making machine} upper mold, saving time and labor. -

Vibration motor

The pure copper core vibration motor is durable, it has strong power to press down the raw materials to ensure the material be beautifully formed. -

Power control cabinet

The power control cabinet has a simple structure, is easy to operate, and it is durable to make the machine for brick making} operates stably.

● Types and applications of brick making machines

The brick making machine is a type of equipment that processes raw materials such as soil, cement, stone powder, sand, industrial waste, slag, etc. into brick blocks. The main working principle of brick making machine is to use pressure to combine the raw materials together, transforming them into bricks suitable for baking or solidifying, for wide application in subsequent construction projects.

There are various types of brick making machines. Depending on the raw materials used, it includes clay brick making machines (also known as mud brick making machines) and concrete brick making machines (also known as cement brick making machines); according to the automation level of the brick making machine, it can be divided into manual brick making machines, semi automatic brick making machine and auto brick making machines. Auto brick making machines mainly utilize a high-end electrical control system to achieve automatic brick forming processes, featuring simple operation and high efficiency, and are widely used as industrial brick making machine, suitable for large and medium-sized brick factories or cement product plants. On the other hand, semi automatic brick making machines require manual involvement in many steps, so with lower production efficiency. However, they are quite affordable and are favored by many small and medium-sized users and home workshops.

The brick making machine in this article is a semi automatic cement brick making machine, although it is a small scale brick making machine, it can produce bricks of various sizes and types (such as solid bricks, flowerpot bricks, fence bricks, etc.), suitable for construction in horticultural gardens, park areas, pedestrian walkways, and other pavement construction sites.

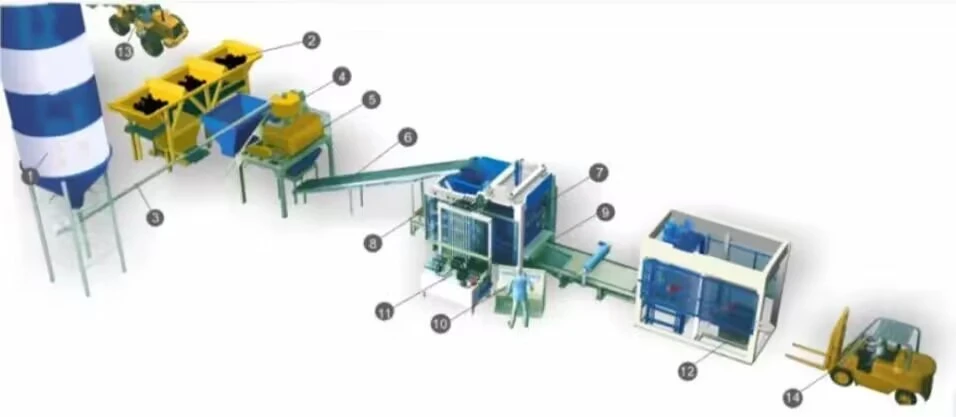

● Brick making machine production line

In order to meet the different production capacities demands, our small brick making machine can be combined with other equipment to form various scales of modern brick making machine production lines. Each modern brick making machine production line can be equipped with multiple brick making machine moulds to produce various sizes and shapes bricks.

1. Semi Automatic Cement Brick Making Machine Production Line

This small scale brick making machine can be combined with mixer and belt conveyor to form a semi automatic cement brick making machine production line. You only need to pour the raw materials which prepared in the required ratios into the mixer, then they will be transported to the brick making machine hopper by the conveyor belt. Operators manually push and pull the brick making machine molds, pull down the material-discharging lever of the semi automatic brick making machine, to make the materials fall into the brick making machine moulds. The operators then flatten the dropped raw materials manually, pull down the forming lever, and the semi automatic brick making machine will proceed with the molding and demolding of the bricks. Finally, the newly formed wet bricks are manually transported to the designated location via trolley or forklift.

2. Small-Scale Automatic Brick Making Machine Production Line

When a brick making machine automatic is equipped with a automatic pallet feeder, automatic pallet remover, hydraulic control cabinet, PLC computer control cabinet, automatic material laying machine, brick making machine moulds, conveyor belts, mixers, and other equipment, it can form a automatic cement brick making machine production line. Typically, such an automatic brick making machine production line requires 2-3 operators. Depending on the size and type of bricks produced, there are multiple models of automatic brick making machines to choose from. A set of small-scale automatic cement brick making machine production line can produce 20,000 to 80,000 standard bricks per day, with prices ranging from around $12,000 to $50,000.

3. Large-Scale Fully Automatic Cement Brick Making Machine Production Line

If you have abundant space and sufficient investment, you can further enhance the small-scale automatic brick making machine production line by adding electronic batching machines, cement silos, fully automatic stacking machines, forklifts, and other equipment to create a truly fully automated brick making machine production line. The large-scale fully automatic brick making machine production line requires 4-6 operators and can produce 150,000-200,000 standard bricks per day, with a price range of approximately $40,000-$120,000 based on different production capacities..

You can also establish your own brick plant. If you are interested in building a brick plant, you can consult us for the necessary equipment. Based on your specific situation and existing equipment, we can provide you with a complete set of supporting equipment and solutions.

● Common troubleshooting of cement brick making machine

During the use of a cement brick making machine, we may meet some common faults. Here are some common faults and their possible causes, and we also show the troubleshooting:

1. The block brick making machine cannot start

This may be due to power failure, poor electrical connections, or motor damage. You can check if the power supply is functioning properly, inspect the electrical connections for looseness or damage, and ensure that the motor of the block brick making machine is working correctly.

2. Uneven mixing of raw materials

This may be due to a malfunctioning mixing device, worn or damaged mixing blades, etc. You can check if the mixing device is operating properly and inspect if the mixing blades need replacement.

3. Insufficient compaction of the bricks

This may be caused by inadequate pressure, inappropriate vibration frequency, or damage to the brick making machine moulds. You can adjust the pressure and vibration frequency of the mini brick making machine to meet the requirements of the bricks, and check if the brick making machine moulds need repair or replacement.

4. Brick shape is Irregular

This may be due to uneven brick making machine moulds or uneven vibration. You can check whether the brick making machine moulds are level, adjust the vibration frequency and time to ensure consistency in the shape of the bricks.

5. The small brick making machine is jammed

This may be caused by excessive raw materials or the conveyor system blocked. You can check if the amount of raw materials being fed is appropriate and clear any blockages in the conveyor system of the small brick making machine.