semi automatic brick making machine production line

The brick making machine is a mechanical device used to produce bricks. The brick making machine for sale described in this article is a semi-automatic brick making machine, it is a type of equipment used to produce bricks. It combines manual and automatic processes to streamline the brick manufacturing process.

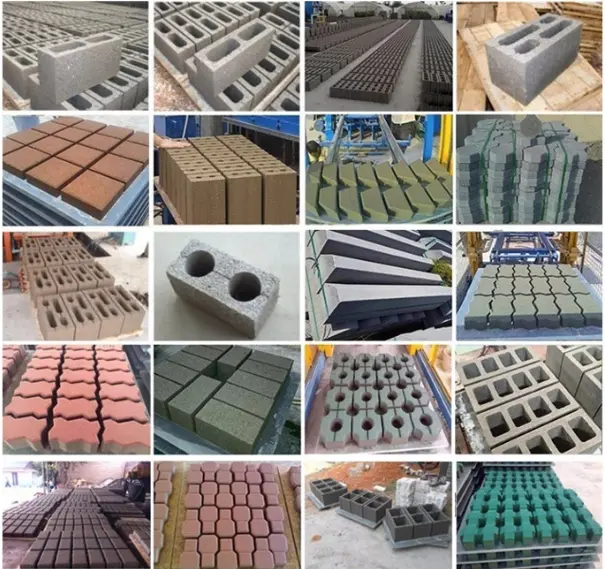

Semi-automatic brick making machine commonly used as a cement brick making machine, concrete brick making machine, ash brick making machine, solid brick making machine, hollow brick making machine, pavement brick making machine, etc. This brick block making machine uses industrial and construction waste such as crushed stone, sand, stone powder, fly ash, slag, slag, and water, along with cement as the raw materials to produce various types and specifications of bricks, such as standard bricks, hollow bricks, permeable bricks, clear water bricks, slope protection bricks, grass planting bricks, curb bricks, colored pavement bricks, etc. Generally, the stock brick making machine only needs to change the mold to achieve multiple uses and produce different types of bricks, making it cost-effective.

Ladrillos semiautomatica sin quemar maquina para hacer ladrillos block 4 26

◆ Features of cement brick making machine

1. This cement brick making machine adopts a four-column guide and is equipped with a powerful vibrating motor. The commercial brick making machine uses directional vertical vibration and upper mold pressure vibration to achieve strong vibration effects with minimal power, ensuring the dense filling of raw materials and greatly improving production efficiency. The blocks produced by this electric brick making machine have uniform density and high strength.

2. The cement brick making machine uses upper mold pushing and manual scraping to produce bricks. It is easy to operate and flexible, and operators can quickly become familiar with it.

3. The machine body of the concrete brick making machine is manufactured by large steel and special welding techniques and materials, making it sturdy, seismic-resistant. The ash brick making machine is equipped with "spring isolation technology" and directional vertical vibration technology at suspension and connection points. This reduces power loss, improves density, achieves good shock absorption, reduces mold wear, and extends the working life of the brick making machine molds.

4. The wooden pallet resonates synchronously with the brick making machine moulds during molding, enduring no impact force, and its service life is more than double that of similar products.

5. The stock brick making machine is versatile, with the option to use different specifications of brick making machine moulds to produce different sizes and types of cement bricks. The replacement of brick making machine moulds is convenient and simple, making maintenance easy.

6. The press head of the cement brick making machine can move longitudinally, facilitating feeding, maintenance, and cleaning. The clearance between the pressing foot and mold box is small, resulting in minimal rough edges on the blocks and a good appearance.

7. This brick making machine for sale is a semi-automatic production line, and the complete set of equipment includes the main brick and block making machine, a mixer, and a conveyor. This greatly enhances the efficiency of brick production. The semi automatic brick making machine is suitable for home workshops and is also suitable for small and medium-sized brick factories and cement product plants.

8. The bricks made by this block brick making machine do not need to be burned and can be put into use with only simple and short-term natural maintenance.

◆ Cement brick making machine parameters

| Brick making machine size | 1800*1500*2250mm |

| Installed capacity | 17.3kw |

| Power | 380V |

| Forming pressure | 8.5 T |

| Main vibration form | Mode vibration |

| Molding quantity | 4-24 pieces |

| Pallet size | 900*500*30 mm |

| Production capacity | 3-person shift produces 3000-18000 pieces |

| Total Weight | 2800kg |

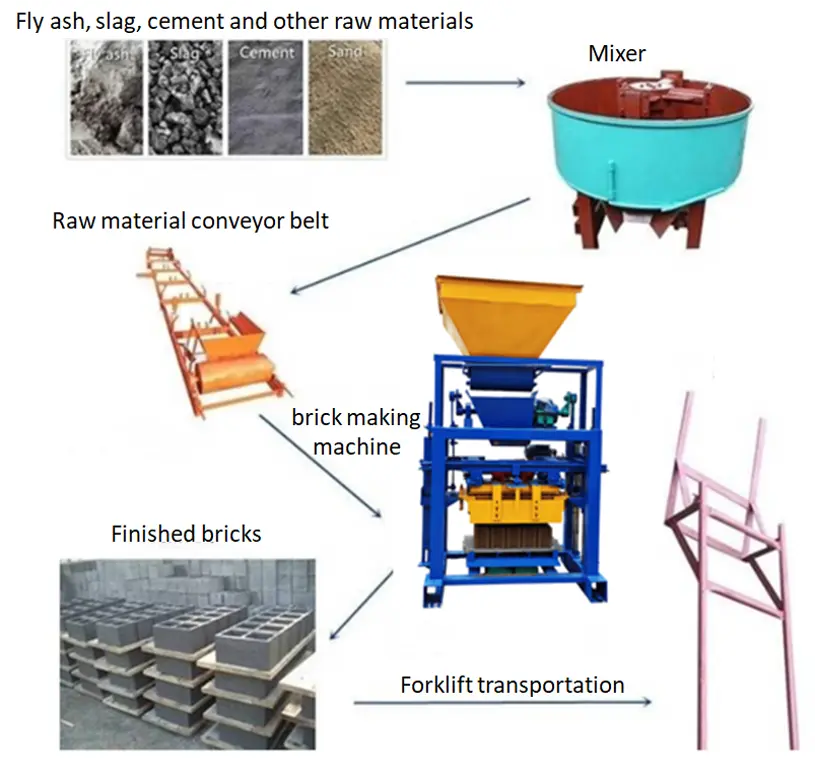

◆ Semi automatic brick making machine production flow chart

The production process of a semi automatic brick making machine typically includes the following steps:

● Raw Material Preparation: Prepare materials such as cement, sand, and stones, and mix them according to a certain ratio. Also, prepare water and other auxiliary materials.

● Mixing: Place the pre-mixed proportions of cement, sand, and stones into a mixing machine (mixer) and mix thoroughly until a uniform concrete mixture is formed.

● Brick Forming: Transfer the concrete from the mixing machine to the cement brick making machine through a conveyor belt. Pull the feeding lever of the semi automatic brick making machine, allowing the concrete to enter the brick making machine moulds. The concrete is then compacted and shaped through mechanical vibration and manual pressure to produce wet bricks.

● Curing: Use a forklift to transfer the freshly made wet bricks on pallets to a designated area for curing, ensuring that the bricks gain sufficient strength during the solidification process. It is important to control temperature and humidity during this process.

● Packaging and Storage: After the bricks have fully solidified, they are packaged and stacked for later sale or use.

◆ Application of cement brick making machine

The cement brick making machine, also known as the brick block making machine, can produce various types of bricks, such as hollow bricks, permeable bricks, bridge deck bricks, full-color bricks, slope protection bricks, and clear water bricks, among others. This semi automatic brick making machine belong s to small scale brick making machine, the block brick making machine design is compact and adopts a frame structure, making it easy to maintain. It features stable performance, high level of automation, and is suitable for various scenarios. The electrical brick making machine exhibits high compressive strength and can produce various types and sizes of bricks by replacing different brick making machine moulds, achieving multi-functional use. This small brick making machine occupies a small area, produces stable products, and boasts high efficiency. This ash brick making machine utilizes materials such as fly ash, slag, industrial waste, construction waste, river sand, gravel, and cement with low cost to produce various types of bricks. Its applications are extensive, including the road bricks for green environmental protection and municipal engineering, permeable bricks, tactile paving, curbstones, slope protection bricks, grass pavers, plaza bricks, driveway bricks, quay bricks, and more.

◆ Brick making machine faults and troubleshooting methods

1. Fault: Unreasonable parameter setting.

Solution: Adjust the block brick making machine working parameters according to the site conditions.

2. Fault: Raw material particles are too large, or the raw materials are of poor quality; concrete mix is uneven; improper dryness or mix ratio.

Solution: During the block brick making machine production, strictly select raw materials according to requirements. If there is no problem with the mix ratio of the concrete, you can adjust the dryness and mix the concrete evenly.

3. Fault: The vibration system of electric brick making machine has problems, unstable vibration or insufficient vibration force.

Solution: Check and repair the vibration system of the cement brick making machine.

4. Fault : The time for eliminating residual vibration is too short, and the vibration box is still vibrating during demolding.

Solution: Lengthen the time for eliminating residual vibration, or adjust the pressure of the cement brick making machine brake valve.

5. Fault: The pallet of the brick making machine is not qualified, for example, the pallet is too thin and lacks strength; uneven thickness within the same pallet, with significant errors; using unassembled substandard wooden pallets, causing fractures at the joints during vibration etc., these may result in the bricks not being formed, especially during the production of block bricks, face bricks, and curbstone bricks.

Solution: Replace the pallet with the ones meet the requirements.

◆ Frequently check the cement brick making machine’s vulnerable parts

1. Check whether there is any looseness in the various parts of the brick making machine moulds, and clean the attachments of the upper mold.

2. Clear away the debris, sand, and dust around the hydraulic cylinder upper column of upper brick making machine moulds. Check whether the nuts and oil pipe joints are loose.

3. Check whether there is any looseness in the synchronous bearing pressure cover and gears of the upper mold, and handle it promptly.

4. Check for the looseness in the upper vibrating transmission parts of the paver brick making machine.

5. Check whether there is any looseness in the various parts of the lower brick making machine moulds, and clean the attachments. When cleaning, it is necessary to pay attention to safety, please place wooden blocks between the upper and lower molds.

6. Check whether the screw of the lower mold compression rod is loose, and adjust it immediately if necessary.

7. Check whether there is any looseness in the oil cylinder and oil pipe joints of the lower mold of the hollow block brick making machine.

8. Remove debris from the grooves in the lower vibration pallet.

9. Check whether the locking nut of the lower vibration support frame has become loose.

10. Check and handle any looseness in the small cement brick making machine lower vibration transmission parts and joints.

● Reasons for deformation of brick making machine pallet

The pallet used in the block brick making machine sometimes may become warped, and the main reasons for this are as follows:

● Improper adhesive ratio.

● Improper hot pressing conditions.

● The glue on the front and back surface of the cement brick making machine's pallet is asymmetrical.

● The pallet of the concrete brick making machine has a high moisture content and causes drying and shrinkage.

To ensure the quality of brick formation, we should take measures to settle the pallet deformation issue, we can start from the following aspects:

● Reduce the amount of urea-formaldehyde resin adhesive to make the adhesive layer soft, and improve the hot pressing conditions.

● After hot pressing, stack the pallets horizontally and press them with heavy objects. Make the fiber direction of the pallet of the concrete brick making machine be parallel to the direction of the base material's dry shrinkage and wet expansion.

● When gluing, squeeze the brick making machine pallet as tightly as possible, leaving the central part slightly loose.

● Reduce the moisture content of the stock brick making machine pallet and ensure its uniformity.