Brick moulding machine

Model: 3-15 cement brick moulding machine

The brick moulding machine uses the slag, slag, fly ash, stone powder, sand, gravel, and cement as raw materials and uses the hydraulic system to press raw materials into the blocks.

This is a 3-15 brick moulding machine for sale. It adopts an advanced design and computer control system. it has the features of a compact structure, strong steel, simple operation, fully sealed and dust-proof, high output, durable, and one machine with multiple uses. The block moulding machine can use various raw to make bricks and reduce the cost of production. In addition, it can replace different moulds to produce different size bricks, including cement bricks, bread bricks, curb stones, road tiles, hollow bricks, and cushion blocks.

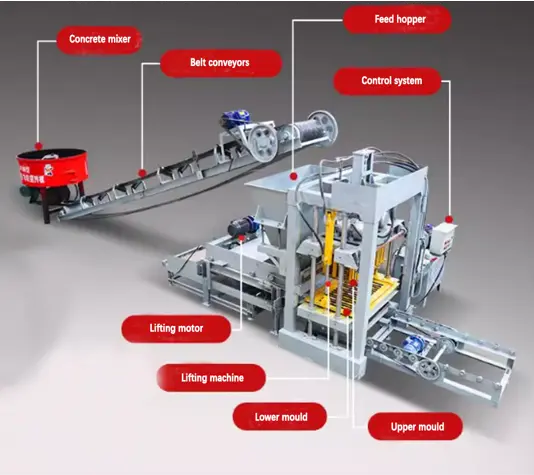

● Brick moulding machine production line

The production line of the cement brick moulding machine includes a feeding system, mix system, Molding system, demolding system, automatic stacking system, hydraulic system, electrical control system, etc.

Raw material: slag, slag, fly ash, stone powder, sand, gravel, cement, etc.

Crusher: Put the materials into the crusher and crush them.

Mixer: Mix the raw materials crushed by the crusher.

Screw conveyor: The screw conveyor transport the mixture to the block moulding machine.

Block moulding machine for sale: Making various sizes of bricks according to requirements.

Hand truck: Use the hand truck to transport the finished bricks to the maintenance site and stacking.

Finished bricks: Drying to form, the brick shape is beautiful.

| Size(mm) | 3000*3600*2300 |

| Molding area(mm) | 700*500 |

| Molding height(mm) | 30-200 |

| Molding cycle(s) | 13-15 |

| Pallet size(mm) | 750*550*30 |

| Weight(t) | 4.5 |

| Power(kw) | 18 |

| Vibration frequency (times/minute) | 4600 |

| Vibration force(kn) | 22 |

1. The automatic block moulding machine can fully automatic production to Save labor costs and improve production efficiency.

2. The moulds can be replaced at any time according to actual requirements to achieve one machine with multiple uses.

3. High vibration force making the finished bricks have the advantages of high strength and good compactness.

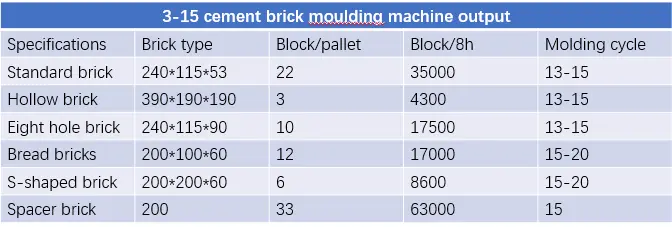

● Concrete brick molding machine output list

● Vibrated block moulding machine features

-

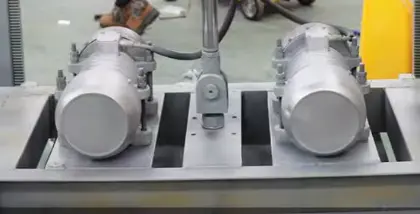

Vibration motor

The vibrated block moulding machine adopts a copper core motor and has the advantage of high temperature resistance, durability, stable operation, and long service life. -

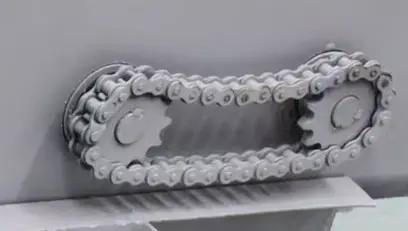

Thickened chain

The vibrating machine for block moulding adopts the thick 1 inch chain and is sturdy and durable, with a smooth transmission, smooth operation, and not easy to damage. -

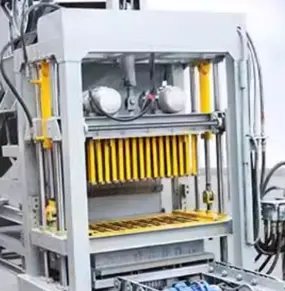

Travel column

The main machine adopts a three-beam and four-column layout, and the four-column guide layout is compact. And has the advantages of high a High precision and accurate positioning.

● Automatic block moulding machine applications

The moulding block machine is normal equipment for the brick factory. It has the advantages of high output, high strength, and a high degree of automation. We can replace different moulds to produce different bricks, such as bread bricks, porous bricks, standard bricks, hollow bricks, exterior wall blocks, interior wall blocks, flower wall blocks, floor blocks, berm blocks, coloured pavement bricks, road tiles, curb stones, pads, etc. There are many types of block moulding machine, and we should choose the suitable machine according to our actual needs. Among them, the 3-15concrete block moulding machine adopts three phases 380 volt voltage and the total power is 24.5 kW. The concrete block moulding machine for sale is driven by the hydraulic and has the feature of no noise, high output, and high density. YANSUMI MACHINERY provides low brick moulding machine price for customers, it has wide applications in buildings, roads, squares, hydraulic engineering, gardens, etc. Next, we will introduce the specific application of the unburnt bricks produced by cement block moulding machine.

1. Building exterior wall

Unburnt bricks have the advantages of thermal insulation, sound insulation, fireproofing, and waterproofing, so they become a new choice for the building exterior wall. It can improve the beauty of the exterior wall and the safety of the building.

2. Indoor

Unburnt bricks can be used in Indoor wall decoration and floor paving. It has the advantages of easy cleaning and low maintenance costs.

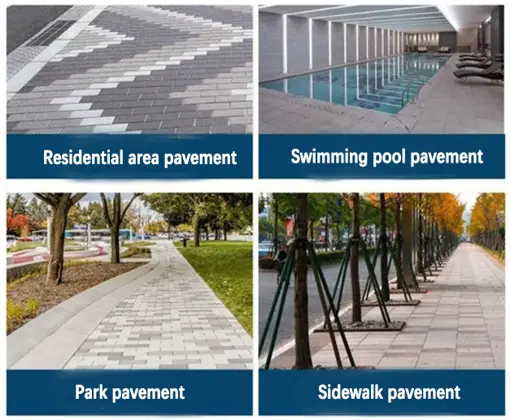

3. Pavement

The unburnt bricks can be used on roads, squares, and sidewalks. It is stronger, more durable, more stable than traditional bricks, and easier to construct and maintain. In addition, the unburnt bricks can absorb noise and reduce noise pollution.

4. Bridge building

The unburnt bricks can be used in bridge building, such as bridge piers, bridge decks, and curbs. Because the unburnt bricks have good anti-corrosion, earthquake resistance, etc, they can improve the safety and stability of the bridge.

● Automation degree of the automatic block moulding machine

The output of the equipment will affect the automation degrees. In general, the small moulding block machine needs one to two operators to operate. The large moulding block machine needs five to six operators. The automation degree of the brick moulding machine for sale is different according to the different production processes. For example, if we need to produce unburnt bricks, The ingredients, mixing, pressing, palletizing, and curing processes are essential. In addition, The automation degrees are also different according to the block moulding machine for sale produced by different factories.

Therefore, we recommend buying the multiple block moulding machine with high automation degrees to improve the production effectiveness and product quality, while reducing the number of required operators and production costs.

● Hollow block molding machine moulds

The moulds of the hollow block molding machine can change the appearance of bricks to meet different brick making requirements. According to the different sizes of the bricks, we can divide moulds into the following types.

Standard brick mould: produces the standard brick.

Hollow brick mould: produces concrete hollow brick.

Pavement brick mould: produces colored pavement tiles, square tiles, and dutch tiles, etc.

Curb stone mould: produces curb stone block.

● Wiring precautions for electric block moulding machine

1, The power main line of the electric block moulding machine should use the aluminum wire above 25mm2 or copper wire above 16mm2.

2, The high voltage of modern block moulding machine should be 380V-410v or low voltage should be 330V-360V. The modern block moulding machine must instal the ground wire to ensuere the safty of the operatier.

3. The wiring of the mobile block moulding machine includes housing wiring and internal electrical wiring. The housing wiring is used to prevent static electricity accumulation, electrical leakage, etc., and external lightning protection measures should be installed.

● Common faults of block molding machine

1. Discharging of the concrete block molding machine is not smooth.

The reason for cement block molding machine discharging is not smooth maybe there is too accumulated material at the feed port, or it may be blocked at the discharge port. For this solution, we can solve it in the following ways.

● Clean the feed port and ensure the feed port is smooth.

● Clean the discharge port.

2. The excessive vibration of the molding block machine.

If the molding block machine is excessive vibration, it can not only affect the stability of the equipment but also affect the quality of the making bricks, for this problem, we can solve it in the following ways.

● Check whether the equipment is fixed. If the equipment is not fixed, it needs to fasten bolts.

● Adjust the eccentric block according to the actual situation.

3. The electric motor of the brick molding machine does not work.

If the electric motor of the brick molding machine does not work. It may be the motor circuit is short-circuited or burned out.

● Check whether the motor circuit is damaged and replace it in time.

● Check whether the junction box and buttons are complete, If it is not complete, it needs to be replaced in time.