Clay brick making machine

Clay brick making machine price: 5500 USD

The clay brick making machine is also called red clay brick making machine, clay brick extruder machine, and clay brick moulding machine. The body of clay brick making machine adopts good steel material, it has the functions of reasonable structure, sturdy and durable body, strong adaptability, low energy consumption, high production efficiency, and simple maintenance. So, the clay brick moulding machine is a wonderful equipment for making various clay bricks.

The clay brick making machine for sale can produce standard bricks ranging from 25 million pieces to 100 million pieces in one year. This model adopts a strong combined unit design and the main shaft bearing seat of the extrusion system is integrated with the mud cylinder to ensure the uniform extrusion of clay. Therefore, the clay brick making machine for sale has the features of high extrusion pressure and high output. The clay brick making machine price of YANSUMI MACHINERY is cheaper than other factories, so our equipment offers a high cost-performance ratio.

◆ Automatic clay brick making machine principle

The automatic clay brick making machine working principle includes the following steps:

1. Preparation: Mix the raw materials in a certain proportion and add water to make clay.

2. Take out air and water: Put the clay into the automatic clay brick making machine, start this machine, and take out the air and water.

3. Forming: The pressure head of the machine starts to push down and make the clay into a clay brick.

4. Care: After the clay brick is formed, send the clay brick to the care areas to start care.

5. Cut: Transfer the clay brick to the automatic cutting machine and start cutting according to the different requirements.

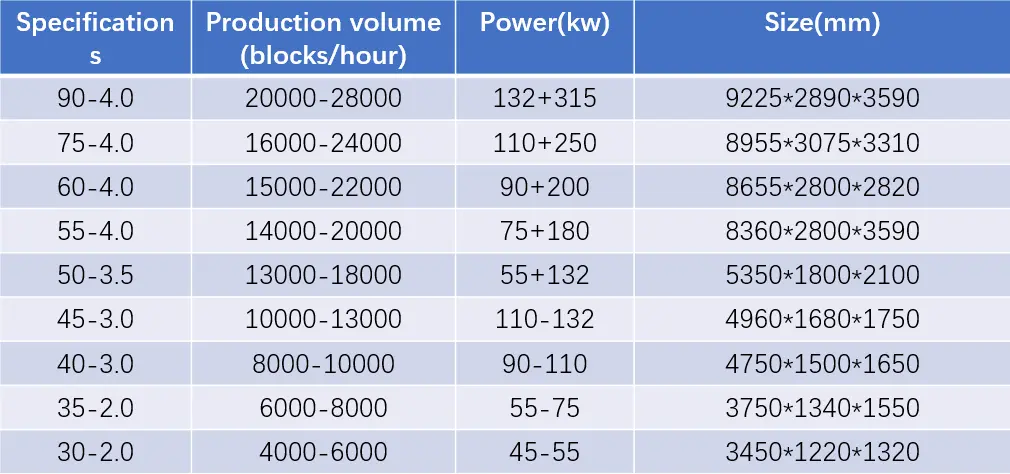

◆ Clay brick making machine parameters

◆ Mud brick making machine applications

The mud brick making machine is the usual equipment to make clay brick. It consists of the machine base, extrusion mechanism, vacuum pump, mixing mechanism, mold, conveyor belt, and control system. The machine base supports the weight of the machine. The extrusion mechanism and vacuum pump are key parts of brick molding. The mixing mechanism can mix the meterails. The mold and conveyor belt are used in delivery and collection. The control system can control the automatic production of mud brick machine. The mud brick making machine price is good and the mud brick making machine has the advantages of high efficiency, energy saving, environmental protection, and intelligence. Therefore, it has wide applications in construction, roads, water conservancy, etc.

The earth brick making machine can use clay, gangue, shale, high content of fly ash, urban construction waste, tailings waste, and inferior soil as materials to make produce solid bricks, load-bearing porous bricks, and hollow bricks. Our brick and block machine has the advantages of novel structure, advanced technology, high output, simple operation, and stable quality.

YANSUMI MACHINERY is one of the best clay brick machine manufacturers in China, we can customize different machines according to different requirements. For example, the clay brick making machine south africa is specifically designed and produced for South Africa customers. Therefore, If you are interested in the clay brick making machine, please contact us, and we will offer more detailed information and support.

◆ Brick making process of soil brick making machine

Brick making process of soil brick making machine: First, the mixing mechanism mixes the clay, sand, and stone powder, and puts the mixture into the soil brick making machine by the conveyor belt. Then the clay was extracted to form the adobe by the vacuum pump and cut into soil bricks of uniform size. Finally, put the soil bricks into the kiln and bake them.

Brick making process of flyash brick machine: Use jaw crusher to crush quicklime——mixing mechanism mixes the various materials——Put the mixture into the hopper——Hydraulic brick machine press molding——Bricks undergo autoclave curing——Drying for 10 days——Brick processing completed

◆ Clay brick extruder machine types

Horizontal double level T-shaped adobe brick making machine

The brick making raw materials enter the first level single shaft extruder, the first level extruder conveying, and extruding raw materials to the second level single shaft extruder. The second level extruder conveys, extrusion, and takes out the air of the adobe. The brick is extruded from the extrusion port of the second level extruder. These two kinds of extruders have an independent set of transmission systems and can be driven separately.

Single level soil brick making machine

The two sets of reamers are driven by a main shaft. The first reamers convey and extrude the raw materials to the vacuum box of the second reamers from the hopper. The second reamers convey, squeeze, and crush the soil, and the vacuum system takes out the air from the soil. Finally, the soil brick is extruded from the front of the vacuum box.

Double level clay brick making machine

This machine is driven by three output shafts. The upper two output shafts drive the upper level twin-shaft mixing extruder. The raw materials enter the upper vacuum box after stirring, squeezing, and chopping by a twin-shaft mixing extruder. Then the vacuum pump takes out the air from the clay and drops it in the lower vacuum box. The lower output shafts drive the extruder in the lower vacuum box. The lower-level extruder transports and squeezes the brick-making raw materials, and then extrudes them into shape from the machine head at the front end.

Combined industrial brick making machine

The combined industrial brick making machine consists of an upper-level mixing and extrusion system and a lower-level extrusion molding system. The difference is the upper-level mixing and extrusion system and lower-level extrusion molding system has an independent drive system. It can be arranged in a parallel line like double level clay brick machine for sale and also can be a T-shaped layout.

Dual extrusion auto brick making machine

The structure of the dual extrusion auto brick making machine is the same as the combined industrial brick making machine. The difference is that one set of upper-level mixing and extrusion systems works together with two sets of lower-level extrusion systems. The purpose is to eliminate the need for large capacity electric motors, large reducers, and large extrusion molding systems, thereby achieving energy efficiency, cost reduction, and ease of maintenance.

◆ Knowledge

1. Different configuration: The clay brick manufacturing machine is equipped with the reducer, barrel, machine base, and other accessories, so it can simply process clay. The vacuum clay brick manufacturing machine equips the vacuum pump, it can remove the air of the clay, so, the clay brick has a good quality.

2. Different weight: The clay brick machine for sale has a small size, and weighs less than 300kg. So, it can easily move and use it in the car. However the vacuum clay brick machine for sale has a more high-end configuration, so, the size of this machine is bigger and the weight is more than 600kg.

3. Different price: The clay brick machine price is cheap, so, it is suited for Family workshops, small factories, and individuals. On the other hand, the vacuum clay brick machine price is higher and it is suited for mid and large factories.

● Clay brick extruder machine operation specifications

During the use of the clay brick extruder machine, we should strictly abide by the following operating procedures.

1. We should check the vacuum pump of the clay brick extruder machine before use and add the lubricating oil for the reducer and vacuum pump according to brick machine manual.

2. We should connect the cooling water before starting.

3. The speed of adding soil should not be fast, we also should check the value of the vacuum gauge and whether the value is within the specified range.

4. We should strictly check the strength and density of the clay and ensure there are no air, cracks, or interlayers in the clay.

5. Check the temperature of the bearings, reduction gearbox, vacuum pump, and mud conveyor, if there are some problems, we should stop this machine.

6. Before stopping clay brick moulding machine, we should stop adding the clay and stop the driven motor after the clay is completely squeezed out. Seal the feeding port and discharge port with a clean plastic cloth.

● Precautions for using semi automatic clay brick making machine

1. Check the lifting and transportation equipment and lifting tools in time and check whether the spiral or blade of the semi automatic clay brick making machine are fixed.

2. The operation of lifting and transportation equipment and lifting tools should according to safe operating procedures.

3. Do not wear gloves to operation and do not put sundries into the clay brick making machine.

4. When performing mud stacking operations, do not choose panels with cracks. Also, ensure that the length of the mud material is appropriate and not too long.

5. We should obey the safe operating procedures to repair the clay brick manufacturing machine, including cutting off the power supply, locking the distribution box, hanging warning signs, and removing the belt of the pug mill.