Concrete batching plant

● What is concrete batching plant?

The concrete batching plant is a fully automatic mixing equipment that mix the raw materials such as cement, sand, stone, and water and make a uniform concrete with the mixer. It is suitable for the construction of houses, roads, bridges, docks, etc.

YANSUMI MACHINERY provides high-quality and affordable concrete batching plant and customize suitable equipment according to your projects.

● Concrete batching plant for sale More

● The concrete batching plant is available in three sizes: large, medium, and small, and is widely used in outdoor construction projects such as highways, bridges, power plants, and dams.

● The concrete batching plant for sale can be used with dump trucks and mixer trucks. In addition, we can customize it according to special requirements to meet different needs.

● The customers should choose the types of concrete batching plant based on the amount of concrete used in the project to achieve the most effective production.

● Our Concrete Batching Plant

HZS25 concrete batching plant

HZS60 batching plant concrete

HZS75 stationary concrete batching plant

HZS90 concrete mixing plant

HZS120 concrete batch plant

HZS180 concrete batch plant for sale

★ The concrete batching plant is available in three sizes: large, medium, and small, and is widely used in outdoor construction projects such as highways, bridges, power plants, and dams.

★ The concrete batching plant for sale can be used with dump trucks and mixer trucks. In addition, we can customize it according to special requirements to meet different needs.

★ The customers should choose the types of concrete batching plant based on the amount of concrete used in the project to achieve the most effective production.

● Our Mobile Concrete Batch Plant

YHZS40 mobile concrete batch plant

YHZS60 concrete mobile batch plant

YHZS75 mobile concrete batch plant

★ The mobile concrete batch plant is a new type of concrete batch plant that integrates feeding, weighing, lifting, and mixing functions into one unit. It can be easily moved and used anywhere.

★ The mobile concrete batch plant for sale has a compact structure, making it easy to maintain. It can be moved without the need for a foundation, saving time and costs associated with construction. Additionally, it reduces transportation, labor, and maintenance expenses.

★ The mobile concrete batch mix plant is suited for construction sites with limited space, short construction periods, and the need for frequent relocation.

● Concrete batching plant solution customization

As a large concrete batching plant manufacturer, YANSUMI MACHINERY can customize concrete batching plant and provide one-to-one batching plant solution, including site selection, product selection, concrete batching plant design, basic construction, acceptance. We can not only increase the overall output of the production line, but also reduce investment costs for customers, and meet the requirements of different customer groups.

Environmentally friendly batching plant of concrete solution

Environmentally friendly batching plant of concrete of YANUSMI MACHINERY integrates high efficiency, energy saving, green environmental protection, noise reduction and dust removal functions, and wastewater treatment. It is easy to install, safe, and smart.

Concrete grades c15-c60

YANSUMI MACHINERY provides the following 10 types of concrete grades to meet different production requirements.

If you need professional concrete batching plant manufacturers to provide the concrete batching plant solution for you. Please contact us anytime, YANSUMI MACHINERY would like to provide you with a full range of services. We will provide you with professional opinions and suggestions in terms of site selection, equipment selection, construction process, output evaluation, and concrete grade. We look forward to providing you with the most optimized solution.

● Concrete batching plant parts

1. Concrete mixer

The concrete mixer is the center equipment of the concrete batching plant, it can mix cement, gravel aggregate, and water into concrete. The concrete mixer can be divided into JS500、JS1000、JS1500、JS2000、JS3000, etc.

The concrete mixers are used for mixing various types of concrete, including plastic, semi-dry, and lightweight aggregate concrete, as well as various mortars and grouts.

The concrete mixer has the advantage of the highly automated, good mixing quality, high efficiency, and easy maintenance.

2. Aggregate batching machine

The aggregate batching machine can be divided into PLD800、PLD1200、PLD1600、PLD2400、PLD3200 and PLD4800 according to the capacity.

The aggregate batching machine can be used with the concrete mixer. It can automatically complete the aggregate proportioning work according to the concrete proportion designed by the user.

The aggregate batching machine has the advantages of high measurement accuracy, high distribution efficiency, and a high degree of automation. It is the most important part of the automatic concrete batching plant.

3. Silo for concrete batching plant

Silo for concrete batching plant is a closed tank for storing bulk materials, such as storing cement, fly ash, and other bulk materials.

We provide various silo for concrete batching plant models from 5T-200T.

4. Screw conveyor

The screw conveyor is used for conveying cement, fly ash, fine sand, and other materials. It is suited for large cement plants and batching plant of concrete.

We offer screw conveyors transporting 15T-80T per hour, customers can choose it according to the actual projects.

5. Automatic control system for concrete batching plant

Automatic control system for concrete batching plant achieves automation and intelligence in the production process, including ingredients, measuring, mixing, and discharging. It can improve the accuracy of ingredients, product quality, and output, and reduce production costs.

Production plans can be easily changed at any time. The concrete mixing ratio can be changed according to different production requirements.

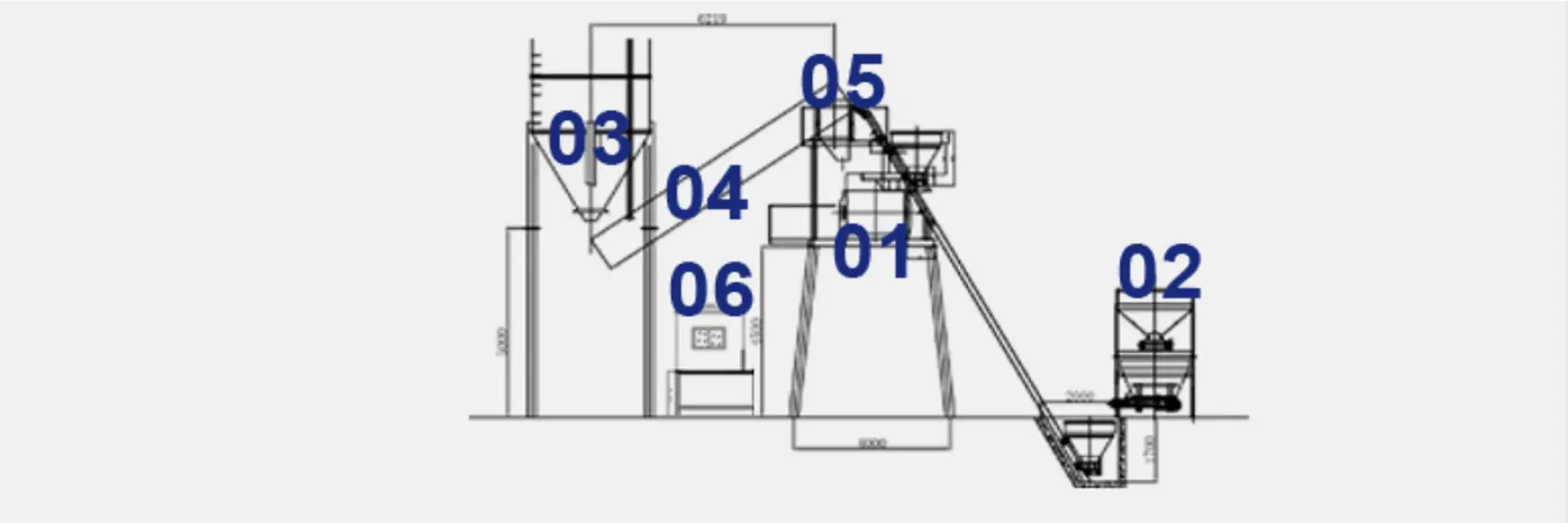

● Batching plant of concrete structure

The batching plant concrete is also called ready mix concrete batching plant and it is a professional mixing equipment for the concrete. The concrete batching plant mainly produces commercial concrete by using cement, fly ash, sand, and gravel, water-reducing agents to mix according to strict accordance with the prescribed standard proportions and transport the concrete to the construction site by a mixer truck.

The concrete batching plant equipment consists of six parts including the mixer, silo for concrete batching plant, batching system, screw conveyor, weighing system, and control system.

1. The mixer is most important in the concrete batching plant components and it adopts the forced mixing method to ensure thorough mixing of the concrete.

2. The concrete plant batching system is to weigh and transport the aggregates, the parameters can be adjusted according to different concrete proportions.

3. The silo for concrete batching plant is a store equipment to store the cement and admixtures.

4. The screw conveyor transport the powdered materials, such as cement.

5. The weighing system is used for accurate weighing of materials. As for the concrete batching mixing plant, the accurate weighing of aggregate, cement, powder, water, and admixtures is very important. In general, The weighing accuracy of aggregate is ≤2%, and the weighing accuracy of cement, powder, water, and admixtures is ≤1%.

6. The automatic control system for concrete batching plant adopts Intelligent control and it can automatically adjust the operating parameters of the concrete batching plant equipment to improve the concrete quality and production effectiveness.

● Concrete batching plant applications

The ready mixed concrete batching plant for sale consists of the mixing system, weighing system, transport system, store system, and control system. The concrete batching plant working principle uses cement as the binding material and mixes the sand, lime, and cinder to make the concrete. It has the high-quality mixer and sophisticated accessories, such as screw conveyors, measurement sensors, pneumatic components, etc. These parts of concrete batching plant work together and improve the production effectiveness. The ready mix concrete batching plant has wide applications in water conservancy, electric power, bridges, airports, ports, and other large facility construction projects and places with the large demand for concrete.

● YANSUMI MACHINERY advantages

1. Concrete batching plant manufacturer with rich experience

YANSUMI MACHINERY has provided more than 100 concrete batching plant solutions for domestic and foreign customers. Our technical expertise allows us to perform concrete batching plant optimization and reduce the concrete batching plant cost to meet different requirements of the customers.

2. Professional team

We have a professional team to design and produce, so, our concrete batching plant design is advanced. The concrete batching plant price is cheap and the quality is good, our product adopts the selection of high-quality raw materials, precision manufacturing, strict multiple testing, and quality guaranteed.

3. Rich products and customizable

We specialize in the production of concrete batching plant equipment and supporting equipment, including the production of concrete batching plant stationery/mobile, concrete batching plant parts, etc. We can offer different concrete batching plant specification and also provide customizable services according to the different requirements of customers.

4. Perfect concrete batching plant service

We have a perfect Pre-sales and after-sales service to help customers use better and faster. We can provide different services such as solution customization, installation, commissioning, maintenance, etc.

So, you can unquestionably choose YANSUMI MACHINERY. If you want to know the concrete batching plant price and more detailed information, you can contact us anytime.