Clay brick making machine for sale

The clay brick making machine for sale can use shale, gangue, and clay as raw materials to produce hollow bricks of various specifications. This machine adopts superior and subordinate structures and it can be installed in a straight line or in a T shape according to different sites. The body of the clay brick making machine for sale is made of welded steel plates. The surface of the reamer adopts a wear-resistant material spray welding process to extend the service life.

The clay brick machine for sale is driven by an electric motor, The reducer controls the upper-level mixing and lower-level extrusion parts simultaneously. So, this machine has a good structure and an obvious energy saving effect.

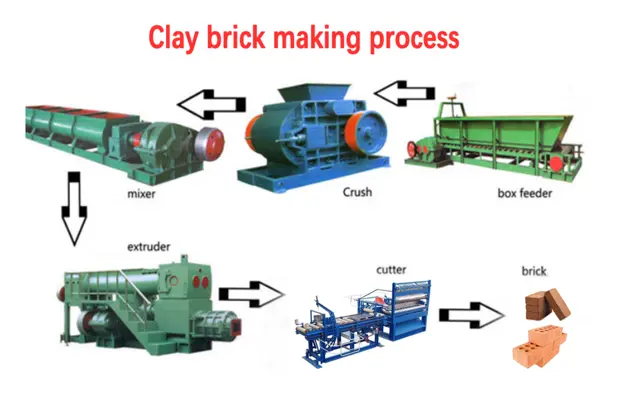

◆ Clay brick making machine working principle

The clay brick extruder machine is made of welded steel plates and has the advantage of reasonable structural design and high extrusion pressure. This machine has strong practicability, small investment, and quick results. It is good equipment for brick factories to increase output.

The clay brick extruder machine uses a combination of vacuum suction and mechanical pressure to make brick. First, put the raw materials into the hopper and mix it with a mixer. Then, put the mixture into the molds and the vacuum pump removes the air from the mixture. At the same time, mechanical pressure compacts the mixture. Finally, the desired hollow brick product is formed.

◆ Maxi brick machine parameters

| Types | JZK 50 |

|---|---|

| Production capacity(piece/h) | 13000-15000 |

| Reamer diameter(mm) | 500 |

| Allowable pressue(MPa) | 3.0 |

| Vacuum degree(MPa) | ≤-0.092 |

| Motor power(kw) | 55+132 |

| Size(LxWxH)mm | 5800*2054*2600 |

◆ Mud brick making machine applications

The mud brick making machine is used to make mud bricks. It consists of brick making machine moulds, hoppers, mixers, forming dies, forming machines, vacuum systems, etc. The mud brick making machine price is good and it has the advantages of high efficiency, energy saving, environmental protection, and intelligence. Therefore, it has wide application in construction, roads, water conservancy, and other engineering fields.

1. Construction industry

The mud brick making machine has wide application in the construction industry. It can produce solid bricks, hollow bricks, etc. These bricks be used in the construction of houses, offices, business centers, and shopping malls.

2. Roads industry

The mud brick machine can produce the pavement bricks for the construction and maintenance of the roads. These bricks can be used in the sidewalks, roads, and squares.

3. Garden industry

The mud brick machine can produce garden bricks for the Garden industry. The garden bricks be used around flower beds and sidewalk edges and beautify the environment and prevent soil erosion.

◆ Ancillary equipment for Soil brick making machine

The soil brick making machine mainly processes the elastoplastic materials composed of a mixture of tiny solid material particles and a certain amount of water. The elastoplastic materials have the features of strong plasticity and low resistance to deformation. First, the raw materials enter the soil brick machine, and the mixer crushes, kneads, and mixes the raw materials. The raw materials enter the conical mud cylinder and are squeezed. Next, the raw materials are cut into slices and entered the vacuum chamber. Then, the vacuum pump removes the air from the clay. Under the action of the spiral, the mud is pushed to the front and gradually pressurized. Finally, the soil becomes a high-density brick embryo.

◆ Clay brick machine advantages

1. The clay brick machine consists of the mixing extrusion part and extrusion molding part. It can be installed in a straight line or T-shaped. This machine equips air compression systems and vacuuming to ensure good product quality.

2. The clay brick moulding machine is made of good steel. It has the features of a reasonable structure, high extrusion pressure, high vacuum degree, sturdy and durable, strong applicability, low energy consumption, high efficiency, and easy maintenance.

3. The reamers of the clay brick moulding machine are made of wear-resistant materials and their life is 4 to 7 times longer than normal reamers. The scientific arrangement of the reamers improves the extrusion pressure and work efficiency.

4. The lubrication of the reduction gearbox uses an electric low-pressure gear pump to ensure sufficient lubrication.

5. The upper/lower bearings adopts lubricated with thin oil, it not only ensures lubrication but also acts as a seal, extending the service life of the bearings.

6. The clay brick machine for sale adopts the appearance of the currently popular model in the world, it has an advanced design to improve the working effectiveness.

7. The important parts such as shafts and gears of clay brick manufacturing machine are made of high-quality carbon steel and alloy steel through heat treatment processes such as tempering or quenching, which extends the service life of the equipment.

8. The red clay brick making machine has a low noise in the working. It is relatively economical in terms of power consumption, with a saving rate of up to 40%.

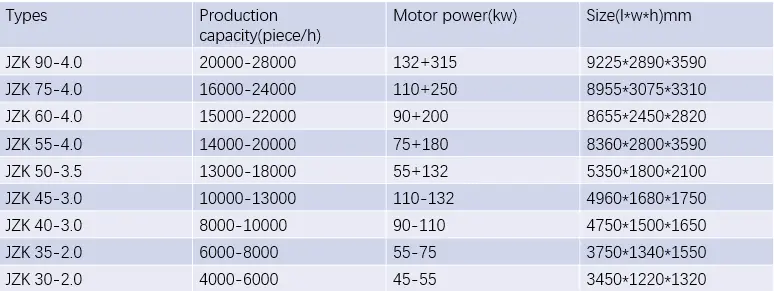

◆ JZK soil brick machine model

The JZK series of the soil brick making machine can use low plasticity raw materials such as shale, coal gangue, high content of fly ash, and infertile soil as raw materials to produce the hollow bricks. The extrusion pressure reached 3.0. Each upper and lower level of the JZK series soil brick machine is equipped with a motor and can be installed in a line shape or a T shape according to the terrain. After the material is stirred in the upper level, it enters the lower level for extrusion and then forms. The types of the JZK soil brick machine include the JZK-50, JZK-45, JZK-40, JZK-30, etc.

● Knowledge of clay brick machine

What are the differences between the single stage and two stages of industrial brick making machine for sale?

The single stage and two stages of the clay brick machine price vary greatly. The two stages clay brick machine price are more expensive. So, what is the difference between the two machines and what is the advantage of the two stages of earth brick making machine?

Difference:

1. The two stages of press brick machine consist of the upper and lower parts, however, the single stage press brick machine is a whole.

2. The two stages of red clay brick making machine need two electric motors to drive, but the single stage of red clay brick making machine only needs one electric motor.

Advantages of earth brick making machine:

1. The extrusion pressure is high and the humidity is low. Brick embryos can be directly put into the kiln for sintering without drying.

2. This model has balanced efficiency and high production output.

3. Easy to maintain, the equipment has an observation room, and we can directly see the scene inside the machine.

● What factors affect the service life of hydraulic brick making machine?

1. Raw materials

The hydraulic brick making machine for sale can use sand, stone, and cement as raw materials, the quality, particle size, and gradation will affect the lifespan of the machine. Therefore, the raw need to adopt the processing process of coarse crushing and fine crushing.

2. Operation method

The operation method also affects the lifespan of the hydraulic interlocking brick making machine. The right operation method can ensure the smooth operation of equipment and reduce wear and breakdown. For example, we need to turn on the conveyor or feeder before starting the machine. In addition, we also should check the operating status of the equipment and abnormal situations should be discovered and dealt with in time.

3. Maintenance

Maintenance is an important factor to affects the lifespan of hydraulic uni brick making machine. The equipment should be regularly inspected, lubricated, and cleaned to reduce wear and breakdown. We should pay attention to the running stats of the machine and find and deal with problems in time. In addition, We also need comprehensive inspections and repairs to ensure the good stats of the machine.

4. Working environment

The working environment can affect the lifespan of the automatic hydraulic brick making machine. The high temperature, humidity, and dust environment can accelerate the wear and aging of equipment. So, we need to use this machine in a good environment and adopt some methods to reduce the effects of dust, moisture environmental factors.

5. Product quality

The quality is the most important factor to affect the lifespan of hydraulic press brick making machine. General, the high quality machine has good durability and stability. So, we need to choose a brick making machine manufacturers with a good reputation and quality assurance.