Small mobile brick making machine

Small mobile brick making machine also known as a portable brick making machine. The common small mobile brick making machine found on the market is mainly a manual brick making machine. It can be moved and used at construction sites or other places where bricks are needed. This type of brick making machine usually has small size and lightweight, making it suitable for small-scale construction projects or personal use.

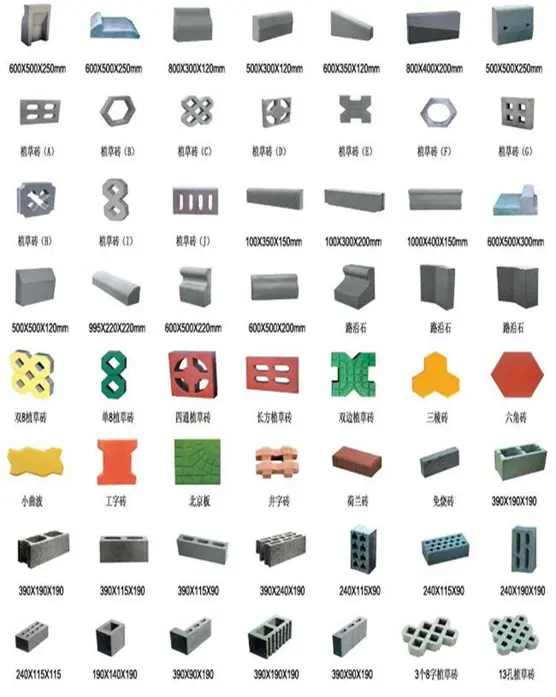

The small manual brick making machine for sale can produce various types of bricks by changing the brick making machine moulds, such as colored pavement bricks, lawn bricks, small concrete hollow bricks, porous bricks, curbstones, and wall blocks. The small mobile brick making machine is easy to operate and maintain, flexible in mold replacement, only requires low investment, yields quick results. The bricks produced by mobile brick making machine has high strength, and the bricks can be removed from the mold of portable brick making machine for sale immediately to save 5-10% of cement. Additionally, the appearance and edges of the blocks are regular. The small mobile brick making machine is currently more ideal models in construction industry.

● Parameters of small mobile brick making machine

| Product name | Small mobile brick making machine / manual brick making machine |

|---|---|

| Voltage frequency | 220V/50Hz |

| Power | 1.1kW |

| Molding time | 45 seconds |

| Excitation frequency | 2000 times/min |

| Vibration frequency | 400Hz |

| Main vibration form | Box vibration |

| transfer method | Pulley |

| Molding pressure | 1.5T |

| greatest pressure | 1.5 KN |

| Dimensions | 900*700*1100mm |

| Package volume | About 0.7 square meters |

| Brick making machine weight | About 200KG |

● Advantages of small mobile brick making machine

1. The small mobile brick making machine only requires one person for production, and it is easy to operate, suitable for people of all ages and genders.

2. The small manual concrete brick making machine uses agricultural electric power and does not require pallets; bricks can be directly made on the ground. This brick and block making machine can produce 2 to 8 blocks at a time, and one person can operate it on the road. This saves you the cost of purchasing pallets.

3. The bricks produced by the small mobile brick making machine are the same as those produced by large-scale maxi brick making machines, and various brick making machine moulds can be used to produce different specifications of hollow bricks, standard bricks, blind hole bricks, sidewalk bricks, lawn bricks, and road tiles. Manual brick making machine is a good machine for rural prosperity.

4. The small manual brick making machine has a wide range of raw materials: stones, slag, river sand, pebbles, expanded perlite, fly ash, ceramsite, construction waste, stone powder, etc., can all be used as the main raw materials for the brick making manual machine. By adding the appropriate amount of cement and using different ratios, the manual cement brick making machine can produce various types of bricks, such as standard bricks, non-standard bricks, paving bricks, load-bearing bricks, non-load-bearing bricks, and lightweight bricks. The bricks produced by the manual cement brick making machine have a complete, dense, and beautiful surface.

-

The (mobile brick making machine) is manufactured by high-strength steel and special welding processes, resulting in a sturdy and durable body, as well as excellent stability and performance.

-

One machine for multiple purposes, you can produce different size and shape bricks by replacing the brick making machine moulds. The small mobile manual brick making machine can be say the most affordable and cheapest brick making machine.

-

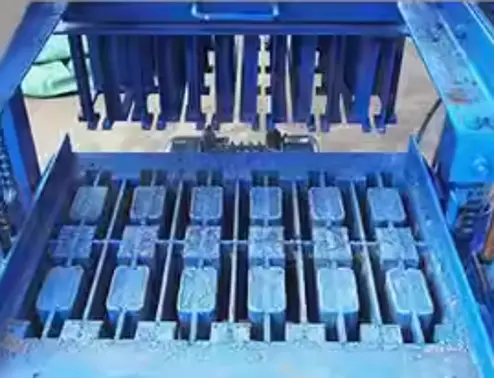

This is an electric brick making machine. Depending on the shape of the brick making machine mold, it can produce 2-8 bricks at a time. The mobile brick making machine does not need pallets and can be manually moved for brick production. The mobile brick making machine does not need a fixed plant, making it a low investment option.

● Small scale brick making machine application

Small scale brick making machine is a machine used for producing bricks. It operates on the principle of vibration molding to produce bricks. During production, the small brick making machine for sale applies top and bottom pressure and strong vibration. The electrical brick making machine is particularly suitable for producing hollow bricks, which have higher filling capacity than red bricks and are non-load-bearing. With different brick making machine moulds, it can also produce various types of bricks, such as hollow bricks, perforated bricks, standard bricks, sidewalk bricks, grass planting bricks, and road edge bricks, among others. This small cement brick making machine features a simple internal structure, compact body, easy operation, easy maintenance, low energy consumption, small investment, and quick returns, making it widely used in construction, roads, squares, hydraulic engineering, gardens, and other projects.

● Small mobile brick making machines are typically small and lightweight, making them easy to carry and move. Mobile brick making machine can be flexibly used between different construction sites and are suitable for scenarios requiring frequent transfers.

● Due to its compact and portable features, and being the cheapest brick making machine, small mobile brick making machines are suitable for individual and small-scale construction projects, such as personal residences, rural housing construction, rural transformation project, and small-scale engineering.

It's worth noting that the production capacity of small mobile manual concrete brick making machine is relatively low and suitable for small-scale needs and projects. If you want to do large-scale brick production, we recommend you to choose larger brick making machine such as the maxi brick making machine. If you are considering to buy brick making machine or you have further questions about small brick making machine for sale or related matters, such as manual brick making machine plans, manual brick making machine prices, maxi brick making machine prices, or have interest in how to make your own brick making machine, and so on, please feel free to contact us for consultation. We are professional brick making machine manufacturers who can help you develop your own plans for brick making machines.

● Difference between mobile brick making machineand stationary brick making machine

1. Different structure

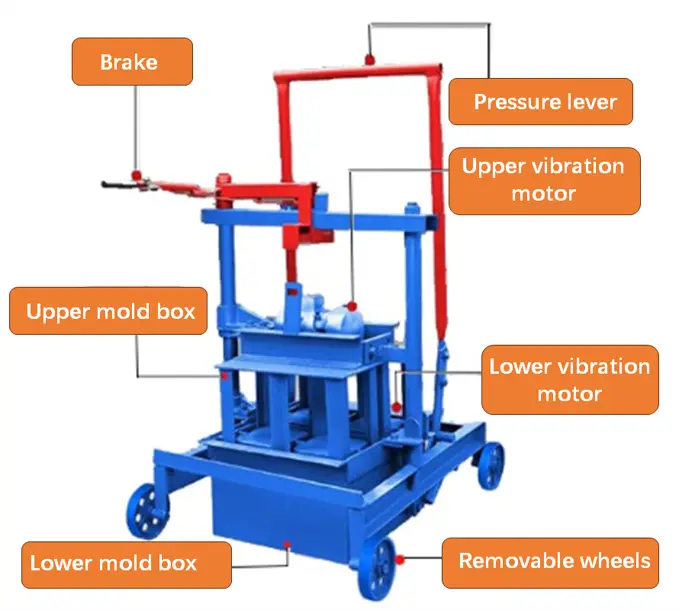

The mobile brick making machine, also known as the portable brick making machine, is equipped with four wheels at the bottom, allowing the brick making machine to move and work flexibly. Mobile brick making machine usually does not have a working platform, and the formed bricks can be directly placed on the ground, which is very convenient and cost-saving.

While the stationary brick making machine needs to be fixed to the ground with anchor bolts. This type of block brick making machine has a relatively large working platform, in order to prevent shaking during production, the block brick making machine and hydraulic pump station also need to be securely fixed.

2. Different operating modes

The mobile brick making machine requires manual operation to move the machine and control its various actions, it is also known as a manual brick making machine, the production efficiency is relatively low.

The stationary block brick making machine does not require manual control. It operates automatically through programmed control, usually be automatic brick making machine. The production efficiency of these auto brick making machines is relatively high, and they are often used in production lines, work together with other more equipment such as mixer, conveyor, pallet feeding machine, etc.

3. Different configurations

The mobile brick making machine has relatively low configuration, as it doesn’t have control system and hydraulic system. It is very simple and relies solely on manual operation of the brick force making machine.

The stationary brick making machine for sale has a relatively high configuration, with an automatic control system that enables the brick force making machine to automatically complete processes such as material feeding, fabricating, brick forming, brick ejection, and stacking.

4. Different production scales

The mobile brick making machine is used for small brick plants, with a small output and scale. These machines often rely on more manual labor to compensate for their limited output.

On the other hand, the stationary brick making machine is generally used for large-scale brick production, with a higher output. It is commonly used in large brick plants, one fully automatic brick making machine can produce over 100,000 standard bricks per day.

stationary brick making machine

stationary semi automatic brick making machine production line