What is pipe bending machine mandrel ?

The pipe bending machine mandrel is a bending tool made of metal material, its function is to provide support and stability to the bending parts. When using the pipe bending machine, if the bending radius of your machine is small and the pips can not be fixed, your pipes bent will have bad bending effects. The pipe bending machine mandrel can help you avoid this problem. The pipe bending machine mandrel can provide support and stability and can also increase the bending radius to meet different bending needs.

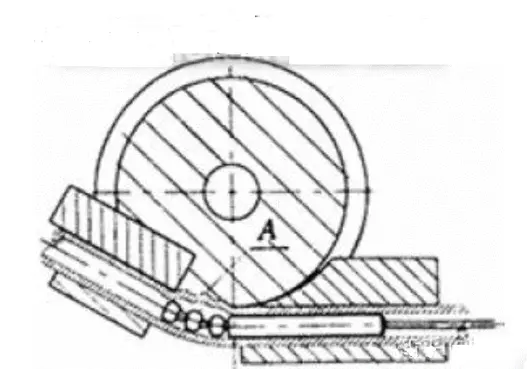

During pipe bending machine operation, the clamping die clamps the metal pipes, and the pipe tightly against the pipe bending machine die, then, the pipe bending machine equipment bends pipes according to the preset curve track. If you use non mandrel pipe bending machine to bend pipes, the bending quality is hard to promise. So, the pipe bending machine cnc and pipe bending machine nc produced by our factory are equiped with mandrel. There are different types of pipe bending machine mandrel, such as column type mandrel, universal single, double, three, and four-ball head mandrel, directional single and multi-ball head mandrel, etc. In addition, the position of the mandrel has an impact on the metal pipes bending effects. Theoretically, the tangent line of the mandrel should be flush with the tangent line of the bending die, but a large number of tests have proven that it is better to exced by 1 to 2 mm.

● Function of pipe bending machine automatic mandrel

1. Provide support

The pipe bending machine automatic mandrel has the function of providing support, ensuring stability during the bending of pipes.The pipe bending machine automatic mandrel can avoid deformation and wrinkles on the pipes, ensuring the normal operation of the bending process.

2. Reduce friction

The automatic pipe bending machine mandrel can reduce the friction of the pipes. The automatic pipe bending machine mandrel comes into direct contact with the inner wall of the pipe, reducing the inner friction of the pipes to reduce the risk of pipe breakage and deformation

3. Increase pressure resistance

The universal pipe bending machine mandrel can withstand pressure instead of pipes, making the pipes keep their original intensity, so, the pipe has stronger pressure resistance. The universal pipe bending machine mandrel also can improve the security and reliability of operation and reduce the problem of deformed or cracked.

4. Improve security

The pipe bending machine aluminium mandrel is inserted into the pipes to provide extra support and fix and prevent pipes from becoming loose or detached during usage. The pipe bending machine aluminium mandrel can also provide an extra layer of security to prevent damage to the pipes.

Therefore, the pipe bending machine mandrel has an important function as a key parts. It has become an integral part of modern industrial production.

● Pipe bending machine for sale mandrel selection

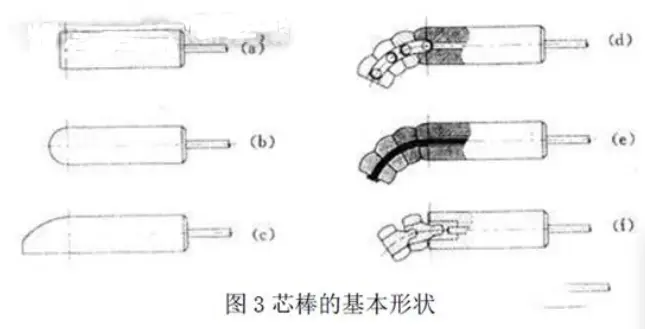

The pipe bending machine for sale mandrel has various types, we should choose different mandrels according to different bending radii, relatively thick wall pipes, and process requirements. In general, the pipe bending machine for sale mandrel can be divided into hard mandrel(a,b,c) and soft mandrel(d,e,f).

(a)Cylindrical mandrel; (b) Ball-head mandrel; (c) Claw-shaped mandrel; (d) Chain mandrel; (e) Flexible shaft mandrel; (f) Ball-and-socket mandrel.

As for the bender pipe bending machine hard mandrel, the cylindrical mandrel(ball-head mandrel) shapes are easy and produce is easy too, the cylindrical mandrel has a wider application than the Claw-shaped mandrel. As for the bender pipe bending machine soft mandrel, the ball-and-socket mandrel is able to flex in many directions, with spherical hinges between each ball joint, able to adapt to various shapes. So, the pipes with thin wall pipes and small bending radii usually adopt the ball-and-socket mandrel. In addition, the number of ball joints of the ball-and-socket mandrel should be chosen according to different relative bending radii, relative pipe wall thickness, and bending angles. If the number of ball joints of the ball-and-socket mandrel is less, it results in bad bending effects. If the number of ball joints of the ball-and-socket mandrel is large, it results in inconvenience for tube penetration.

After choosing the bender pipe bending machine mandrel, the gap between the mandrel and the inner diameter of the pipe is also an important factor affecting the quality of the bent pipe. If the diameter of the mandrel is too small, wavy wrinkles may occur on the inside of the pipe, and the outside part of the pipe will be deformed. If the diameter of the mandrel is too large, the wall pipes will be strained, even, the outside part of the pipe will bulge or rupture. So, the suitable diameter of the mandrel is key to ensuring the bending quality.

● Pipe bending machine automatic mandrel maintenance

●Clean and lubricate

In order to ensure the normal operation of the optimum pipe bending machine mandrel and extend its service life, the clean and lubricating in time is very important.1. Clean: the dirt and dust on the mandrel surface should be cleaned on time. We can use the cleaning agent and soft cloth to wipe the surface of the mandrel and prevent damage to the mandrel of the square pipe bending machine.

2. Lubricate: the mandrel needs to be lubricated to reduce the friction and run smoothly during pipe bending machine working. Apply a suitable lubricant to the surface of the mandrel, dol not use too much lubricant, as it can interfere with the operation and introduce impurities.

● Check and replace regularly

Checking and replacing regularly is an important part of ensuring the performance and safety of the roller pipe bending machine mandrel.1. Check regularly: Regularly check the appearance and structure of the pipe bending machine automatic mandrel and make sure there is no obvious damage, deformation, or wear. Especially, we should notice the connecting parts and support points of the mandrel to ensure the structure is stable.

2. Replace regularly: We should replace the mandrel of the nc pipe bending machine with damaged or severely worn according to usage and actual wear and tear. We should choose a suitable mandrel before replacing it and according to the instructions of the pipe bending machine manufacturers in China to replace it.

Checking and replacing the pipe bending machine mandrel in time to ensure the proper functioning and safety performance of cnc pipe bending machine china, else, the bending accuracy of pipe bending machine is inaccurate because the mandrel is damaged or aged.

Notice: The maintenance is different according to different pipe bending machine china mandrel. So, please read the pipe bending machine hydraulic manual provided by pipe bending machine manufacturers carefully, and follow its recommendations for operation before performing maintenance and service.

+86 19112905173

+86 19112905173