What to do if the pipes wrinkle when bending by pipe bending machine hydraulic?

● Why do pipes wrinkle when using cnc pipe bending machine?

1. The pipe bending machine working principle

The CNC pipe bending machine for sale can bend metal pipes according to the needs. It consists of the pipe bending machine cnc body, hydraulic system, electrical control, and pipe bending machine die. The CNC pipe bending machine design is advantageous and has the advantages of good bending effect, fast processing speed, wide range of use, etc. During the pipe bending machine working, the pipe bending machine die clamps the pipes tightly, and the hydraulic system provides the power to bend pipes at the required angles and radius. However, because of the reasons of uneven pipe wall thickness and improper parameter settings of cnc pipe bending machine for sale, resulting in the inner wall of the pipe becomes wrinkled during the pipe bending process.

2. Wrinkling problem during the bending process of the Chinese CNC pipe bending machine

The problem of inner wrinkling refers to the phenomenon that the inner side near the bending direction appears dented or wrinkled during cnc pipe bending machine china bends metal pipes. This problem will result in the inner wall pipes becoming uneven and increasing the coefficient of friction. It can potentially lead to the accumulation of dirt and impurities inside the pipe, thereby affecting its normal usage.

3. The influence of cnc pipe bending machine hydraulic operation method on wrinkle problem

During the pipe bending process by cnc pipe bending machine hydraulic, we should consider many parameter settings, such as pipe thickness, bend radius, angle, etc. It will result in the problem of inner wrinkling because of the wrong parameter settings and operations. For example, if the pipe bending machine die is not suitable or the bending power is large, it causes dents or wrinkles inside the tube and affects the normal usage of pipes.

● Solutions of wrinkling during the bending process of pipe bending machine

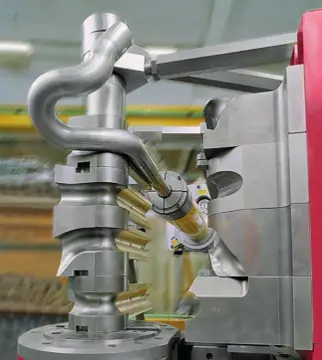

If you use mandrelless pipe bending machine for pipe bending, the inner of pipes may collapse and produce significant wrinkles. As shown in the picture, so, choosing the suitable pipe bending machine mandrel is the first step to solving the problem of wrinkling of pipe.

● The pipe bending machine mandrel

1. Determine the type and size of the pipe bending machine round mandrel: Choosing the suitable type and sizes of pipe bending machine round mandrel according to the bending requirements and Characteristics of pipes. For common mandrel types including hard mandrel and soft mandrel, we should consider the Stiffness, wear resistance, and high-temperature resistance of the mandrel.2. Adjust the position of the hydraulic round pipe bending machine mandrel: The hydraulic round pipe bending machine mandrel should be put inside the pipes correctly. The tangent line of the hydraulic round pipe bending machine mandrel should be flush with the tangent line of the bending die. But a large number of tests have proven, that the tangent line of the mandrel should exceed the tangent line of the bending die by 1 to 2 mm and the bending effect will be better.

3. Ensure the stability of oval pipe bending machine mandrel: The oval pipe bending machine mandrel should be stable and avoid shaking or shifting while using the oval pipe bending machine. We can improve the stability of the mandrel by reducing the mandrel length or adding fixed equipment.

4. Adjust the bending parameters of the large pipe bending machine: The bending parameters of the large pipe bending machine are very important for the usage effectiveness of the mandrel. According to the different types and sizes of pipes, adjust the bending speed, and bending power and choose suitable dies to ensure the mandrel valid supports the inner of the pipes.

5. Check the quality of the pipe: After using the large diameter pipe bending machine to bend pipes, we should check the quality of the pipes. Check for wrinkling, sinking, or deformation to ensure the mandrel is working well.

● The pipe bending machine wiper die

Because the material on the inner side of the pipe is in an extruded state, the pipes also may be wrinkled, even if we use the pipe bending machine mandrel to support the pipes. In this situation, the automatic pipe bending machine can be able to add the wiper die to avoid wrinkles. So, what is the wiper die? The wiper die is like a scraper. It is installed in the bending die and moves along the inner wall of the bend. During the pipe bending process, when the pipe passes through the wiper die, the wiper die will scrape off the excess material in contact with the pipe surface, making it smooth and eliminating defects such as inner wrinkles and waves. As shown below, the wiper die is installed on the side of the bending die of the pipe bending machine, and the leading edge of the wiper die is tightly pressed against the bending die.

So, the position of the pipe bending machine best wiper die and the inclination angle of the wiper die and the pipe has an effect on bending quality. If wrinkles appear in the pipe, we should solve this problem according to the following steps.

1. Extra add wiper die.

2. If wrinkles still appear on the pipe, please adjust the position of the pipe bending machine wiper die and closer to the cutting point of the bending die.

3. If the best bending effects are not achieved, reduce the wiper die inclination angle.

4. Finally, if the bending effects are not still good, we should consider replacing the materials of the pipes.

So, how can we determine from the beginning whether the pipe bending machine hydraulic needs a wiper die as shown in the table below?

| CLR/Tubediameter | 1XD | 1.5XD | 2XD | 2.5XD | 3XD | 5XD | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Bending Angle | 90° | 180° | 90° | 180° | 90° | 180° | 90° | 180° | 90° | 180° | 90° | 180° |

| 10 | P | P | P | P | P | P | P | P | N | P | N | N |

| 20 | MB1 | MB1 | MB1 | MB1 | MB1 | MB1 | P | P | P | P | P | P |

| 30 | MB2 | MB3 | MB2 | MB3 | MB2 | MB3 | MB1 | MB2 | MB1 | MB2 | P | P |

| 40 | MB3 | MB3 | MB3 | MB3 | MB3 | MB3 | MB3 | MB3 | MB2 | MB3 | P | MB1 |

| 50 | MB3 | MB4 | MB3 | MB4 | MB3 | MB4 | MB3 | MB4 | MB3 | MB3 | MB1 | MB2 |

| 60 | MB4 | MB5 | MB4 | MB5 | MB3 | MB4 | MB3 | MB4 | MB3 | MB4 | MB3 | MB3 |

| 70 | MB4 | MB5 | MB4 | MB5 | MB3 | MB4 | MB3 | MB4 | MB3 | MB4 | MB3 | MB3 |

N= No mandrel required;

P= Straight-end mandrel;

B= Single ball head mandrel;

MB=Ball head mandrel, the number represents the number of ball heads;

The wiper dies are recommended for dark gray areas.

When using the pipe bending machine for sale to bend pipes of different bend angles, diameters, and thicknesses, we should replace the pipe bending machine mandrel and wiper dies according to the actual situation. The customer can able to choose the suitable pipe bending machine mandrel and wiper dies according to the shown in the table above to improve the bending effects.

Except for the above problems, there is another more challenging wrinkling defect situation. As shown below, the wrinkles are very slight and distributed throughout the bend area. After checking the position of the pipe bending machine mandrel and wiper dies, the position and angle are all correct. So, for this situation, we can consider the following solutions:

1. Check whether the size of brass pipe bending machine mandrel is too small.

2. After confirming the position and angle of the pipe bending machine mandrel and wiper dies are correct, increase the pressure of the pressure die.

In reality, the actual cause that affects the occurrence of wrinkles is how we control the material flow during the pipe bending process. So, the wire pipe bending machine mandrel and the wiper die cooperate with each other and can able to get good bending quality.

The key to resolving the issue of inner wrinkles lies in understanding and controlling the flow direction and tendencies of the material. In order to meet different application scenarios and quality requirements, we can flexibly combine the process means of the pipe and tube bending machine. In this way, we can improve the bending effects and bending quality.

+86 19112905173

+86 19112905173