Troubleshooting for tube bending machine

The round tube bending machine is often used as exhaust tube bending machine(exhaust mandrel bender ) and boiler tube bending machine(boiler tube bender) in automobile manufacturing industry and boiler manufacturing industry. The rectangular tube bending machine often takes part in production of chairs. The tube bending machine for sale of Yansumi Machinery is widely used in the production of different products. Mandrel of the tube bending machine with mandrel can support inside of tubes and the tubes can maintain roundness after being bent. As a professional cnc tube bending machine manufacturer, Yansumi Machinery provides our clients not only nc tube bending machine and cnc tube bending machine for sale for their production but also guidance of tube bending problems and solutions to help them get better bending quality.

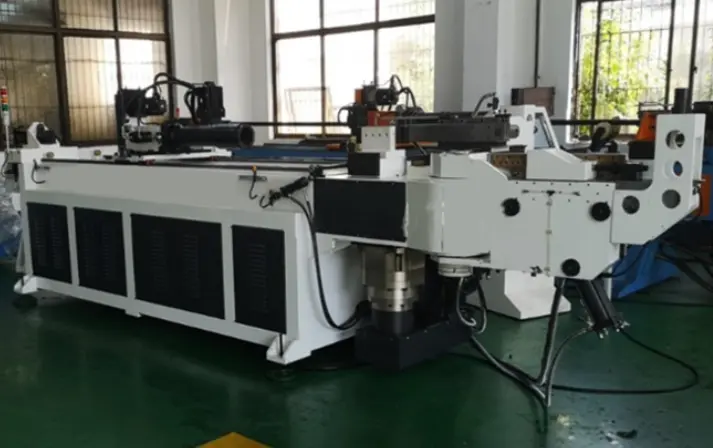

dobladora de tubos para escape cnc

The tube bending problems and solutions that clients may encounter when they use tube bending machine to bend pipes.

1. The outside of pipe arc becomes flat.

1. Tube bending defects: The outside of pipe arc becomes flat.

This happens because there is no support inside the pipe during the pipe bending process. To solve this problem it’s necessary to use some tool to prop up the inner pipe wall. This tube bending machine with this tool is tube bending machine with mandrel. Measurement and shape of the mandrel should be selected according to the diameter and wall thickness of the pipe. The mandrel should be well installed: the central axis of the grooves of all tube bending machine dies( bending die, pressure die, clamping die, anti-wrinkle die and mandrel) should be on the same plane.

2. Tube bending defects: The outer wall of the arc becomes very thin.

In order to avoid excessive thinning of the pipe wall the commonly used and effective methods is to bend pipes with stainless steel tube bending machine with a device that gives extra power at the side or at the rear of the machine. The extra power of the device on aluminum tube bending machine can cancel out some friction during the pipe bending process, improve the stress distribution on the cross section of the pipe and make the neutral layer move outward, so as to reduce the thinning of the outer wall of the pipe.

3. Tube bending defects: The outer wall of the arc cracks.

First, check pressure from the big tube bending machine pressure die. Tube cannot move smoothly if too much pressure from the pressure die of aluminium tube bending machine and will lead to crack of tube. Move backwards the pressure die to keep a little distance from the tube so that the pressure die can hold the pipe less firmly and the tube can move smooth through the pressure die of aluminium tube bending machine. Secondly, make sure that there are good lubrication between the mandrel of tube bending machine with mandrel and inner wall of the pipe to reduce friction during the bending process.

4. Tube bending defects: There are wrinkles on the inner side of the arc.

Take corresponding measures according to the wrinkling position.

①If there are wrinkles at the start point of the curve, move the mandrel of the small diameter tube bending machine a little more forward to ensure that the mandrel is supporting the pipe wall all the time.

②Use large tube bending machine anti-wrinkle die if there are wrinkles at the end point of the curve. It’s necessary to make sure that the anti-wrinkle die is on the proper position of the round tube bending machine. At the same time, adjust the pressure die position on the nc tube bending machine to ensure the proper pressure from the pressure die.

③There are two possible reasons if wrinkles are on all the inner side of the arc.

The diameter of the big tube bending machine mandrel is too small. This will lead to the big distance between the big tube bending machine mandrel and the pipe wall and affects the pipe bending effects.

Solution: measure the mandrel diameter, change the mandrel for a bigger one.

(2) The pressure of the tube bending machine hydraulic pressure die is not big enough to make the pipe fit well with the bending die and anti-wrinkle die of the large tube bending machine during the bending process.

Solution: adjust the position of the pressure die of the tube bending machine with mandrel and make it to offer more pressure.

In this article we talk about the methods to improve pipe bending quality, there are more blog on our web that can help to know more about how to achieve the good bending quality.

+86 19112905173

+86 19112905173